Deinking agent for waste paper

The technology of deinking and saponifying agent for waste paper is applied in the field of deinking agent and deinking agent for waste paper, which can solve the problems of unstable performance and excessive fiber loss of waste paper, and achieve the effect of good papermaking performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

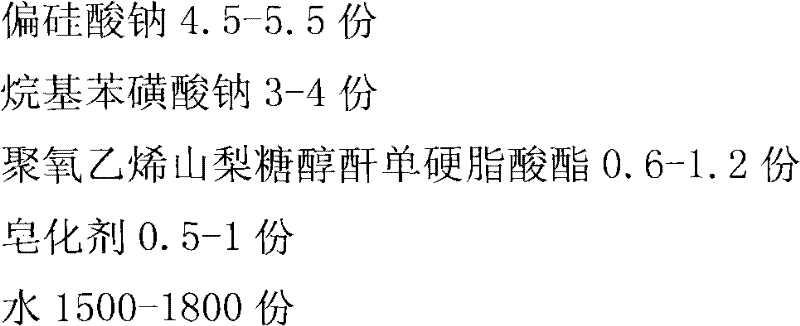

[0010] Put 4.5 kilograms of sodium metasilicate, 3 kilograms of sodium alkylbenzene sulfonate, and 0.6 kilograms of polyoxyethylene sorbitan monostearate into the reaction tank, then add 1500 kilograms of water and stir evenly, and the water temperature rises to 50°C, then put the waste paper into the tank and soak for 2 hours to deink, and the deinked slurry is washed 3 times with a cylinder deinking agent to remove ink particles.

Embodiment 2

[0012] Put 5 kilograms of sodium metasilicate, 3.5 kilograms of sodium alkylbenzenesulfonate, and 1 kilogram of polyoxyethylene sorbitan monostearate into the reaction tank, then add 1600 kilograms of water and stir evenly, and the water temperature is raised to 55°C, then put the waste paper into the tank and soak for 2.5 hours to deink, and the deinked slurry is washed 3 times with a cylinder deinking agent to remove ink particles.

Embodiment 3

[0014] Put 5.5 kilograms of sodium metasilicate, 4 kilograms of sodium alkylbenzene sulfonate, and 1.2 kilograms of polyoxyethylene sorbitan monostearate into the reaction tank, then add 1800 kilograms of water and stir evenly, and the water temperature rises to 60°C, then put the waste paper into the tank and soak for 3 hours to deink, and the deinked slurry is washed 3 times with a cylinder deinking agent to remove ink particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com