Method for controlling nonmetal inclusions in X70 stage acidoresistant pipeline steel

A technology of non-metallic inclusions and control methods, applied in the manufacture of converters, etc., can solve the problems of inclusions that are harmful and fail to reach X70 steel grade, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

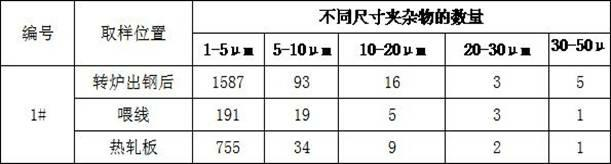

Embodiment 1

[0024] A method for controlling non-metallic inclusions in X70 grade acid-resistant pipeline steel provided in this embodiment includes:

[0025] (1) Desulphurization pretreatment of molten iron requires strict slag removal operation. After slag removal, there should be no residue on the surface of the molten iron. It is required that the molten iron [S]≤0.002%, and spray Mg for strong desulfurization treatment;

[0026] (2) Guarantee that the number of times of carbon pulling at the end of the converter is ≤1 time; the end point of the converter [S]≤0.008%, [P]≤0.008%; converter tapping pre-refining: complete the slag fluorite, active lime, aluminum before tapping 2 / 5 Incorporation of lumps and alloys;

[0027] (3) Deep desulfurization during the refining process, refining with high alkalinity and strong reducing slag, the alkalinity of the slag is 7, the treatment time: 40min, the S content in the molten steel is controlled to be ≤15ppm; the LF treatment process meets the [A...

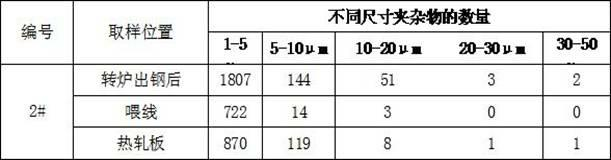

Embodiment 2

[0031] A method for controlling non-metallic inclusions in X70 grade acid-resistant pipeline steel provided in this embodiment includes:

[0032](1) Desulphurization pretreatment of molten iron requires strict slag removal operation. After slag removal, there should be no residue on the surface of the molten iron. It is required that the molten iron [S]≤0.002%, and spray Mg for strong desulfurization treatment;

[0033] (2) Guarantee that the number of times of carbon pulling at the end of the converter is ≤1 time; the end point of the converter [S]≤0.008%, [P]≤0.008%; converter tapping pre-refining: complete the slag fluorite, active lime, aluminum before tapping 2 / 5 Incorporation of lumps and alloys;

[0034] (3) Deep desulfurization in the refining process, refining with high alkalinity and strong reducing slag, the alkalinity of the slag is 10, the processing time: 50min, the S content in the molten steel is controlled to be ≤15ppm; the LF treatment process meets the [Als]...

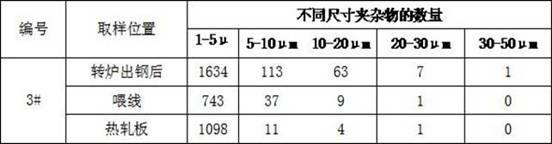

Embodiment 3

[0038] A method for controlling non-metallic inclusions in X70 grade acid-resistant pipeline steel provided in this embodiment includes:

[0039] (1) Desulphurization pretreatment of molten iron requires strict slag removal operation. After slag removal, there should be no residue on the surface of the molten iron. It is required that the molten iron [S]≤0.002%, and spray Mg for strong desulfurization treatment;

[0040] (2) Guarantee that the number of times of carbon pulling at the end of the converter is ≤1 time; the end point of the converter [S]≤0.008%, [P]≤0.008%; converter tapping pre-refining: complete the slag fluorite, active lime, aluminum before tapping 2 / 5 Incorporation of lumps and alloys;

[0041] (3) Deep desulfurization during the refining process, refining with high alkalinity and strong reducing slag, the alkalinity of the slag is 15, the processing time: 60min, and the S content in the molten steel is controlled to be ≤15ppm; the LF treatment process meets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com