Main power house for side-position arranged turbine generator

A technology for turbo generators and main workshops, applied in industrial buildings, etc., can solve the problems of shortening the length of high-temperature piping systems, reducing engineering investment, and high investment, and achieves the goals of improving normal operation efficiency, reducing engineering investment, and improving investment returns Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

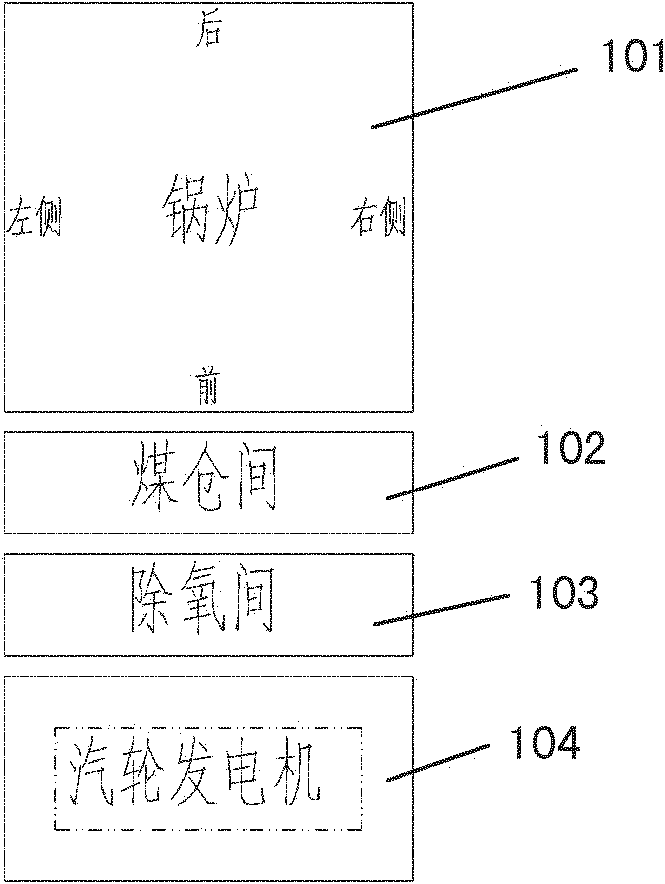

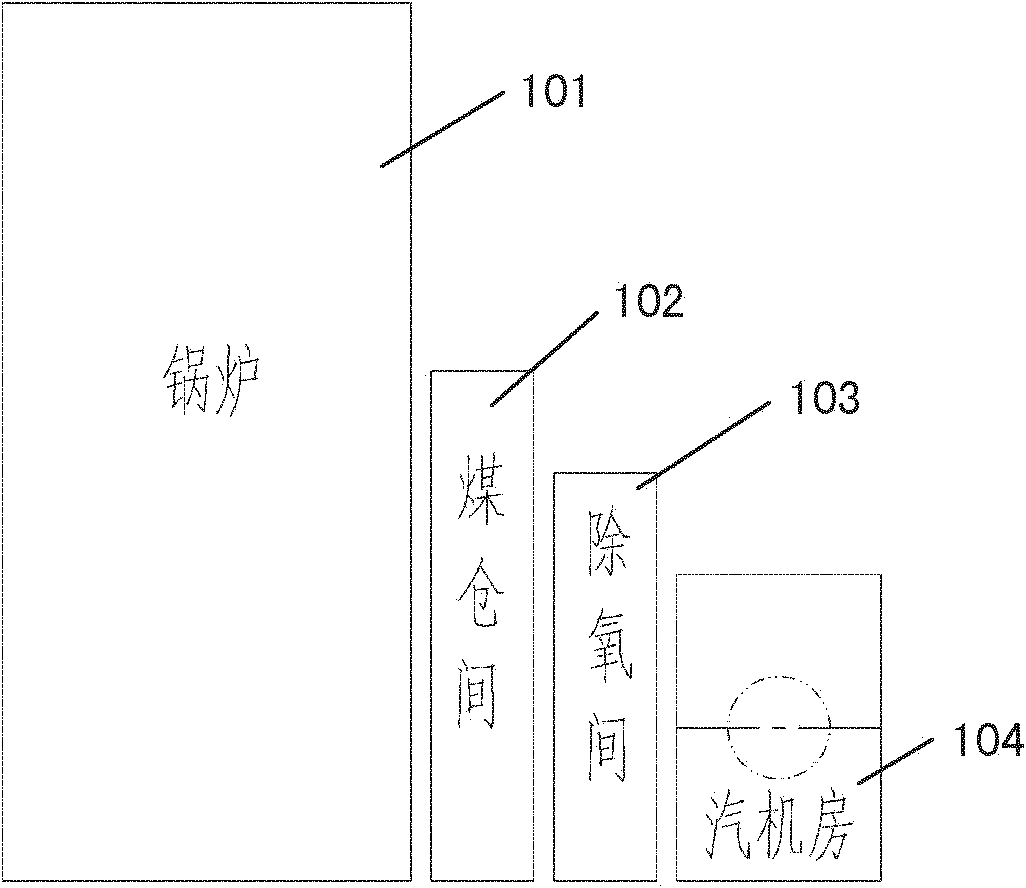

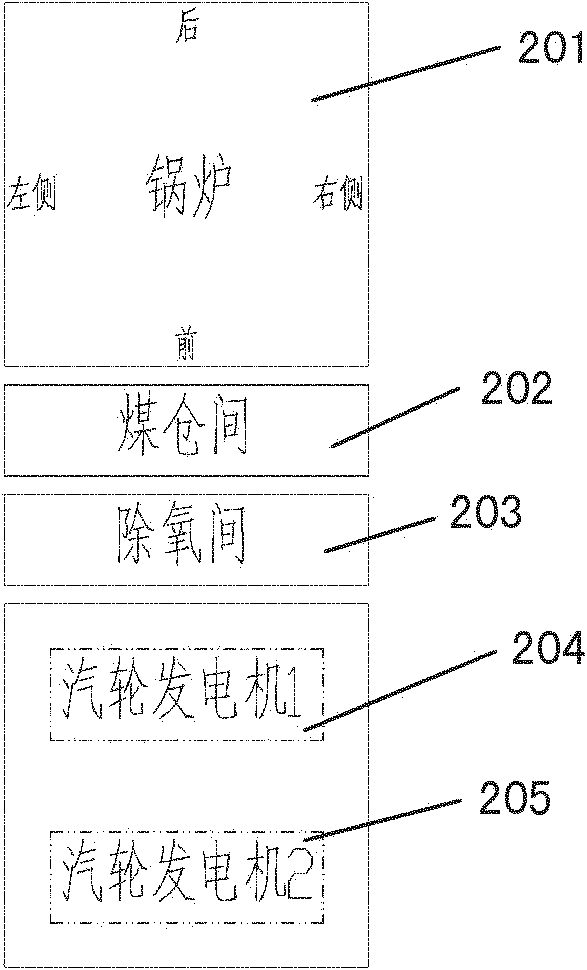

[0028] Aiming at the problems of long distance between the high temperature interface between the steam turbine and the boiler, long piping system, high investment, large flow resistance and low efficiency caused by the large distance between the steam turbine and the boiler in the conventional front position arrangement in the prior art, the present invention proposes a This is the main powerhouse with the steam turbine generator room arranged sideways. The main workshop includes a boiler room, a coal bunker room, a deoxygenation room and at least one turbogenerator room, wherein one of the at least one turbogenerator room is arranged adjacent to one side of the boiler room.

[0029] According to one aspect of the present invention, the above-mentioned at least one steam turbine generator room is a single-shaft turbo-generator machine room, wherein the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com