Toothed thread drill stem joint

A threaded drill and rod joint technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problem of insufficient torsional strength and bending fatigue life of API threads, stress concentration at the root of API male joint threads, and fatigue sensitivity of API threads Coefficient of high, to reduce fatigue sensitivity, solve fatigue or brittle fracture, improve the effect of bending fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

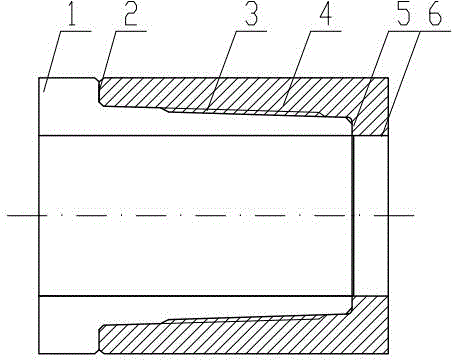

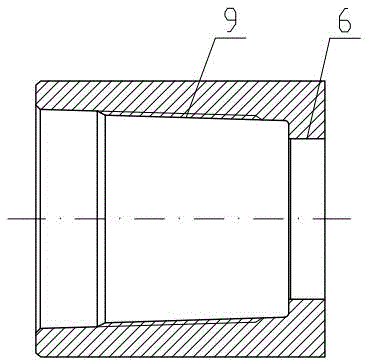

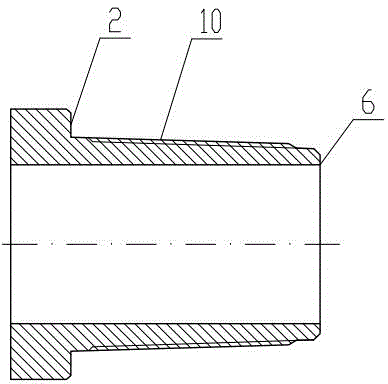

[0023] According to attached figure 1 It can be seen that the present invention specifically relates to a threaded drill pipe joint, including a female joint 4 and a male joint 1, both of which are hollow structures, and the outer wall of the male joint 1 has an axially extending An external thread 10, the inner wall of the female joint 4 has an axially extending internal thread 11, and both sides of the internal thread 11 and the external thread 10 are provided with a section of smooth base, and the outer side of the smooth base is provided with steps, so The female joint 4 and the male joint 1 are screwed together as a whole. The internal thread 11 and the external thread 10 are tooth-shaped tapered threads, and the taper of the tooth-shaped tapered threads is 1:8~1:16. The dedendum 8 and the dedendum 7 are arc-shaped structures, and there is a gap at the joint between the dedendum 8 and the dedendum 7, and two sealing surfaces 9 are formed at the joint of the tooth side; C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com