A kind of niti and ti6al4v dissimilar metal composite welding method

A hybrid welding and dissimilar metal technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as brittle fracture, reduce welding deformation, increase service life, and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, but the present invention should not be limited to the examples.

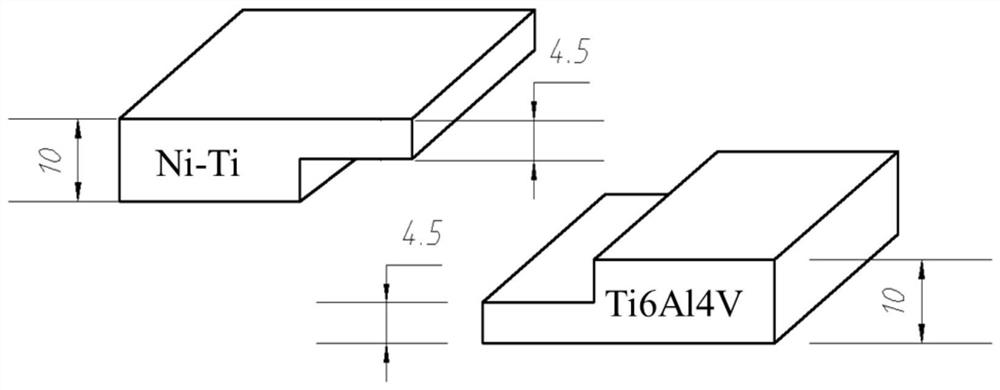

[0020] This embodiment uses Ti6Al4V alloy and Ni-Ti alloy as the implementation objects, and the specific dimensions are as follows figure 2 shown.

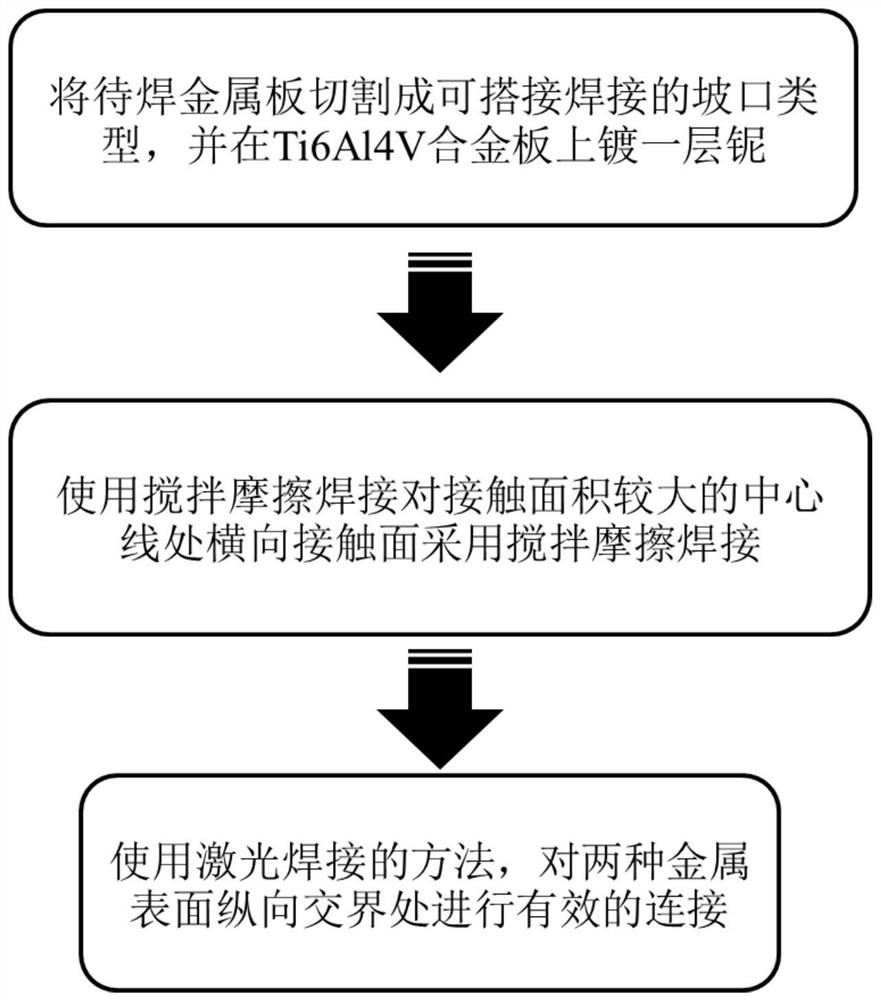

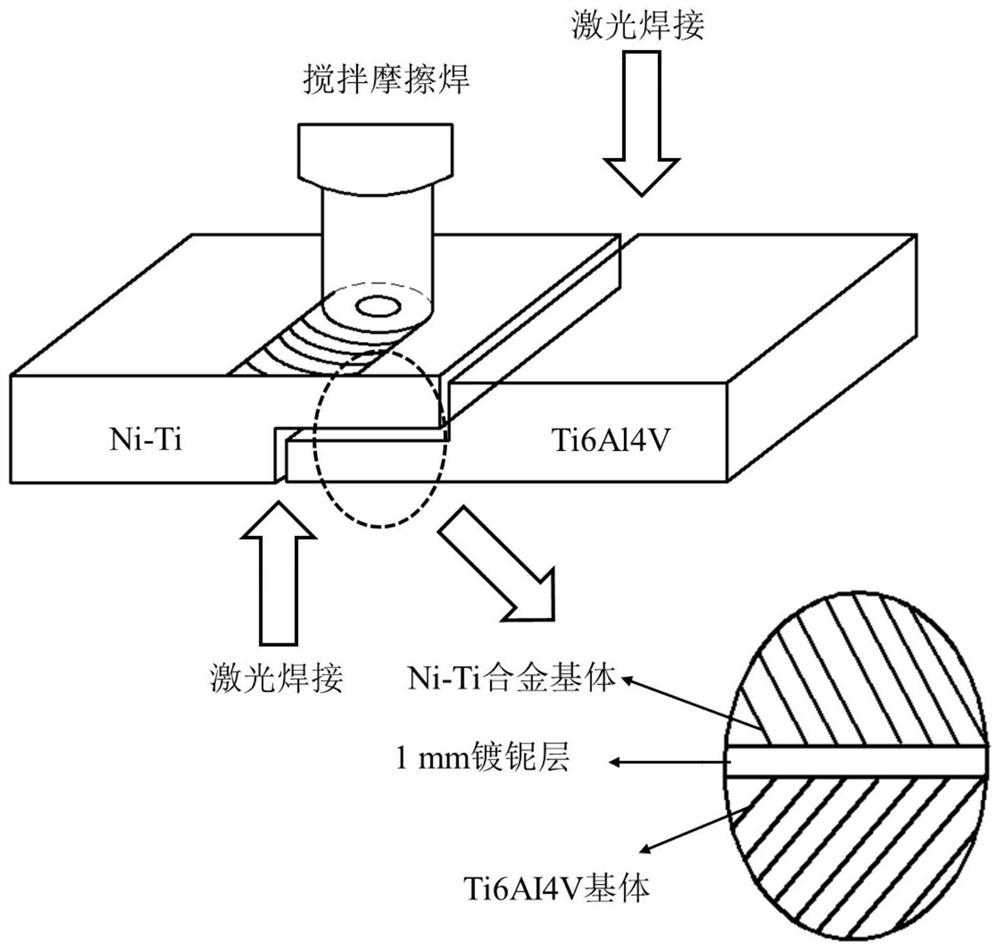

[0021] A kind of example of NiTi and Ti6Al4V dissimilar metal composite welding method, its concrete steps are:

[0022] (1) Cut two steel plates with a thickness of 10mm into a groove type that can be lap welded, and the groove thickness of the cut plates is 4.5mm.

[0023] (2) Texturize the upper surface of the groove of Ti6Al4V. The textured area is a rectangular area with a distance of 5 mm from the edge of the groove, and the surface roughness of the textured area is greater than or equal to 5 μm. Use acetone solution to clean the surface of Ti6Al4V to remove surface oil and dust,

[0024] (3) Coating a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com