High temperature resistant silicon molybdenum ferritic nodular cast iron for steam turbine and its preparation process

A nodular cast iron and preparation technology, applied in the field of nodular cast iron and its preparation technology, can solve the problems of increasing casting production risk, increasing production cost, prolonging production cycle, etc., and achieve the effects of shortening production cycle, saving resources and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The product in the following examples is the medium-pressure outer cylinder of a double-reheat steam turbine of Shanghai Electric. Its main wall thickness is 60-350 mm, partly 500 mm, and its pouring weight is 64.0 tons.

[0043] The material is a kind of high temperature silicon molybdenum ferrite ductile iron for steam turbine, the mass percentage of each component is as follows:,

[0044] C 3.0~3.5%, Si 2.8~3.2%, Mo 0.5~0.8%, Mg 0.040~0.055%,

[0045] Sb 0.004~0.008%, Mn<0.2%, P<0.040%, S<0.015%,

[0046] Re<0.010%, the remainder is iron and residual elements.

[0047] The following table is the composition value of each embodiment:

[0048]

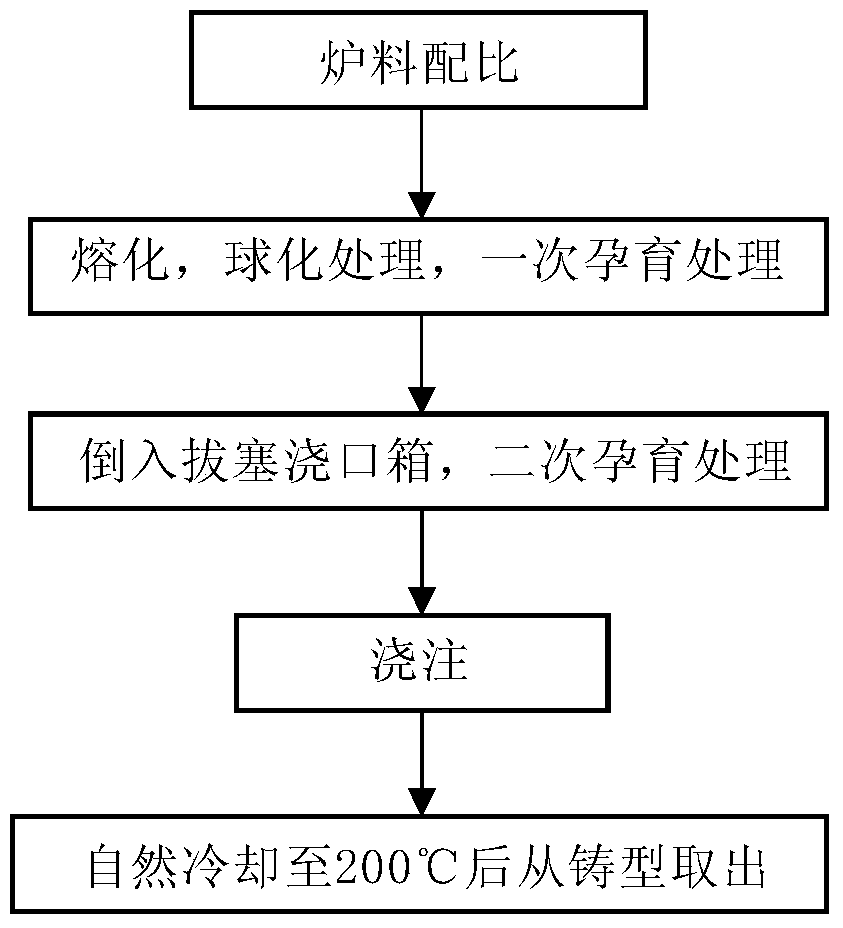

[0049] The preparation process steps of the high temperature resistant silicon molybdenum ferrite nodular cast iron product for above-mentioned steam turbine are as follows (asfigure 1 shown):

[0050] a. Furnace charge ratio: 50 parts by weight of pig iron, 30 parts by weight of carbon steel scrap, 20 parts by weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com