Sliding guide rail with micro-pit oil pockets on surface of base

A sliding guide, base body technology, applied in the direction of engine lubrication, engine components, linear motion bearings, etc., can solve the problems of rapid wear and large frictional resistance, and achieve the effect of good wear resistance, reducing friction and wear, and guaranteeing life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawings and examples.

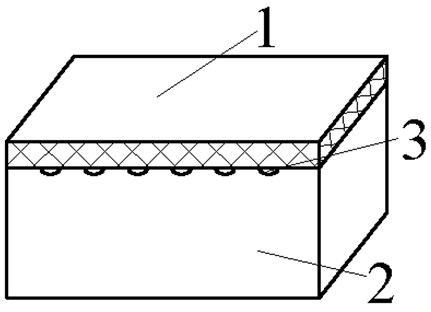

[0028] Such as figure 1 As shown, the present invention has evenly distributed micropit oil bags 3 on the surface of the static guide rail substrate 2, and a layer of soft material 1 is bonded on the static guide rail substrate 3.

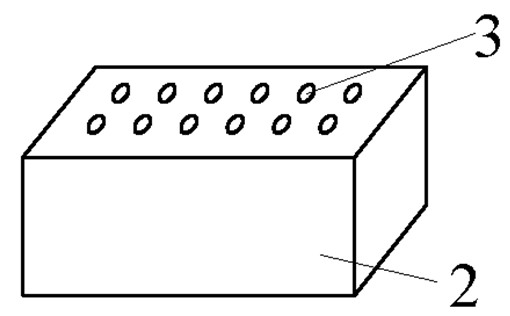

[0029] Such as figure 2 As shown, the micropits 3 on the surface of the base body 2 of the static guide rail are arranged in parallel and equidistantly along the length direction of the static guide rail. Or along the length direction of the static guide rails, multiple parallel ones, each equidistantly arranged in dislocation.

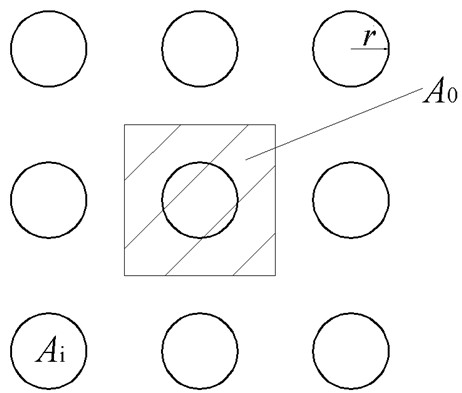

[0030] The total area of the micropit oil pockets 3 on the surface of the static guide rail base 2 is 5% to 20% of the surface area of the static guide rail base. Such as image 3 , the area ratio of the oil pocket area of a micropit to the corresponding matrix area .

[0031] The depth-to-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com