Ceramic anchoring nail for castable liner

A castable and anchoring nail technology, applied in the direction of lining support, etc., can solve the problems of high temperature on the outer wall of the equipment, easy to be corroded, cracking of the castable lining, etc., and achieve the effects of reducing heat dissipation loss, investment, and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

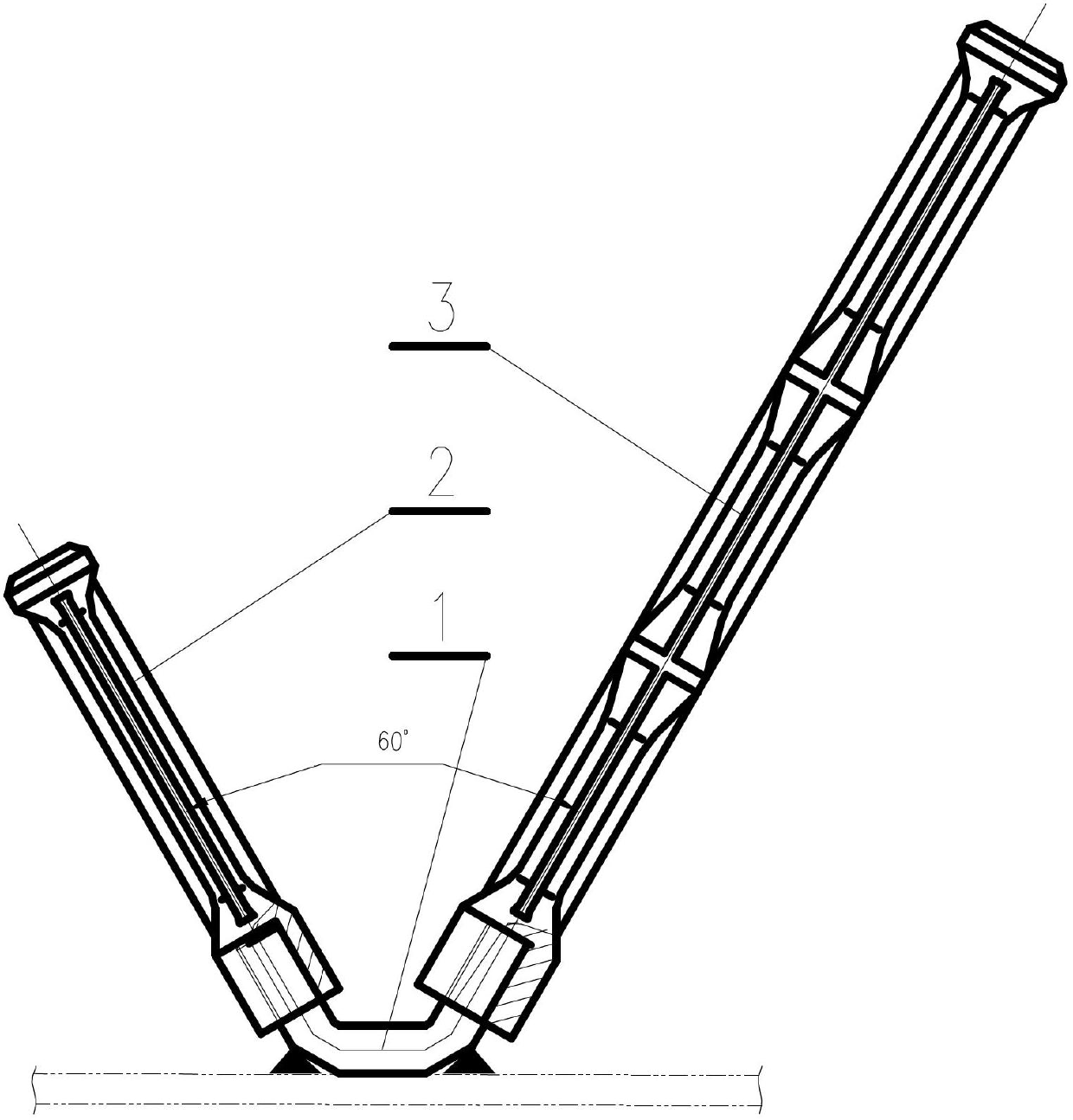

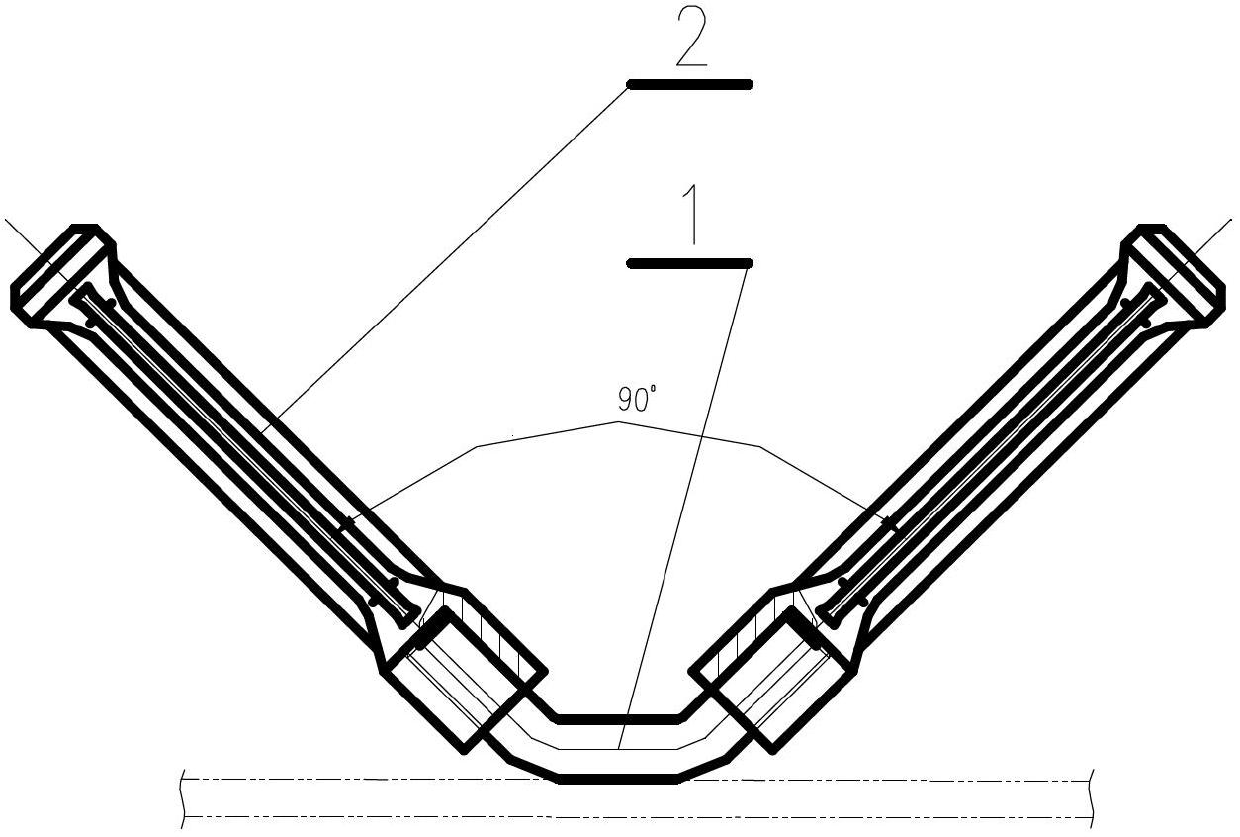

[0027] Such as image 3 , 4 As shown in and 5, a ceramic anchoring nail for castable lining according to the present invention includes a base nail 1 and a pair of nail bodies, and the base nail 1 is in the shape of a "V". Such as figure 1 , 2 As shown, the pair of nail bodies are respectively fixedly connected with the two ends of the base nail 1 in a "V" shape.

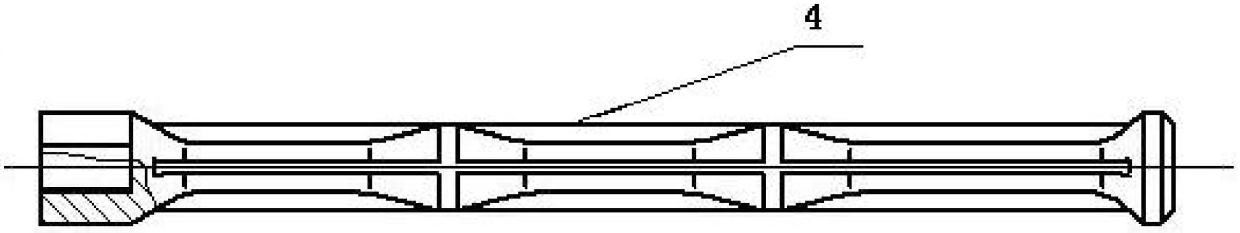

[0028] The nail body of the present invention includes long nails 3 or short nails 2, and Al 2 o 3 Content greater than 90%, ZrO 2 It is sintered from a toughened composite ceramic material with a content greater than 3.7%. The cross-section of the nail body is circular, and the basic geometric shape adopted is cylindrical. In order to enhance the rigidity of the nail body and improve the adhesion of the lining, the following design is adopted:

[0029] 1. A total of 4 ribs are set at a ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com