COD (chemical oxygen demand) online monitoring instrument

A technology of monitor and photoelectric detector, applied in the direction of instruments, analytical materials, etc., can solve the problems of high reagent cleanliness, frequent maintenance, errors, etc., and achieve low reagent consumption, low maintenance, and low failure. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The above scheme will be further described below in conjunction with the accompanying drawings and examples.

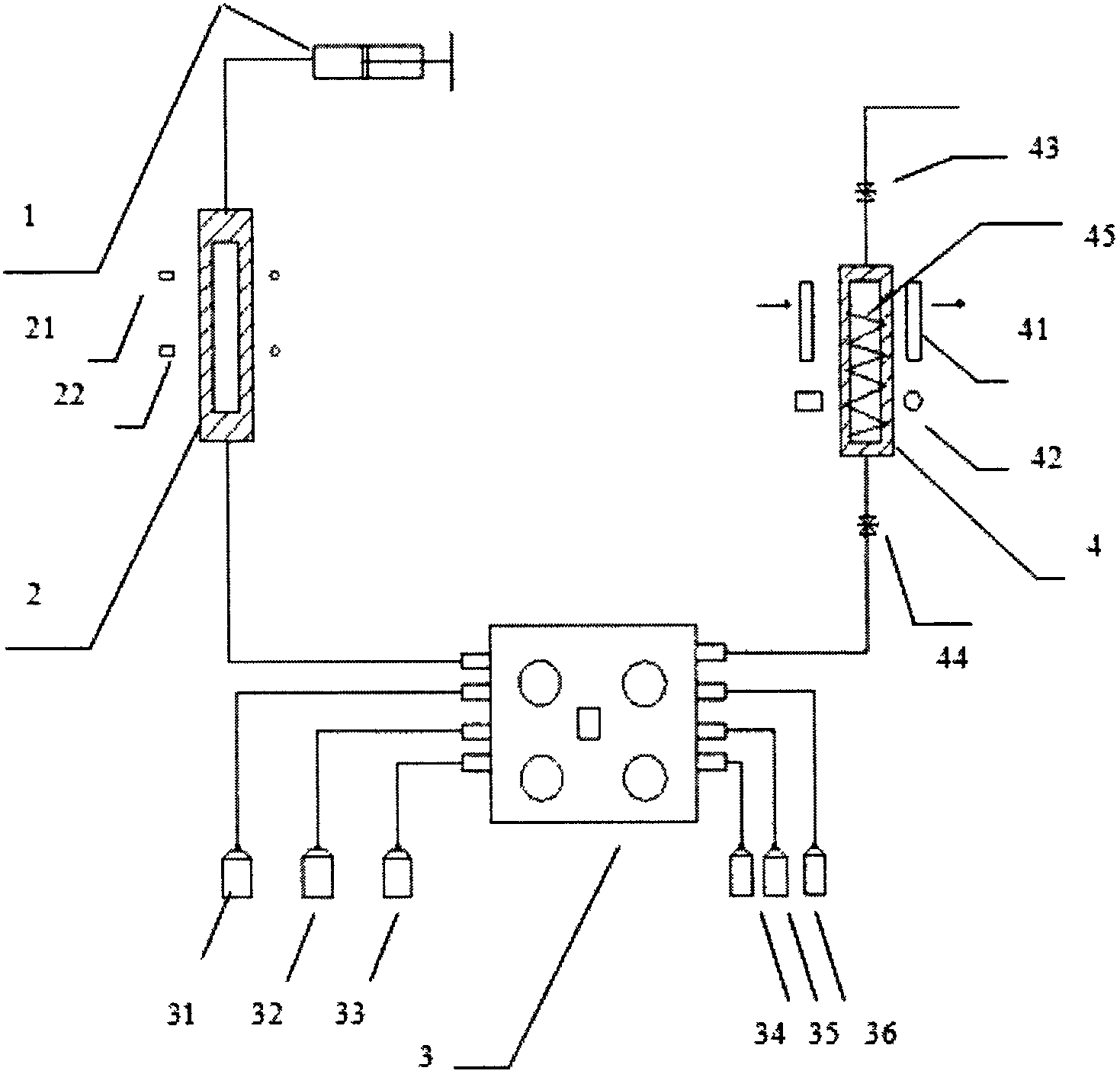

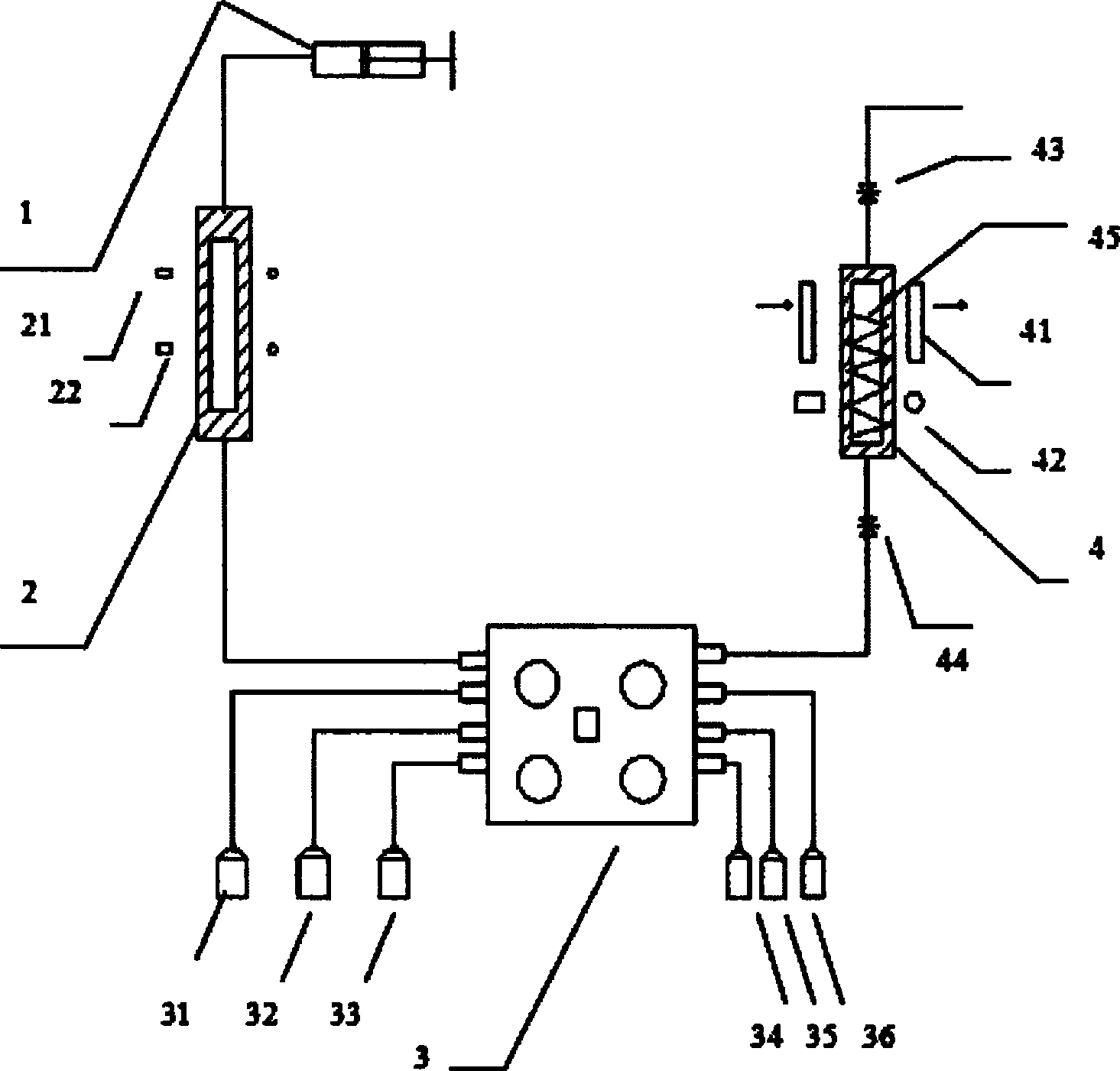

[0019] Example figure 1 , a kind of COD on-line monitor, including the sample and reagent storage device and the reaction device connected with the control pipeline of the PLC control system and the photoelectric metering tube 2 connected with the control pipeline, the piston for sample injection is arranged outside the pipeline Pump 1, the sample and reagent storage device includes multi-way valve 3 selectable open and close water sample bottle 31, zero point standard solution bottle 32, COD standard solution bottle 33, masking agent solution bottle 34, oxidant solution bottle 35, catalyst solution bottle 36. The multi-way valve 3 selects to open and close the water sample or the reagent pipeline to control the sample injection. Described reaction device comprises heating wire 45, digestion colorimetric tube 4, fan 41, colorimetric light source 42, upper elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com