Simple and convenient autonomic and automatic meter adjustment method

A meter calibration and automatic technology, applied in the direction of instruments, measuring devices, measuring electrical variables, etc., can solve the problems of product quality impact, unfavorable production automation, low adjustment accuracy, etc., to ensure stability and reliability, and to facilitate production automation , The effect of streamlining the calibration steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

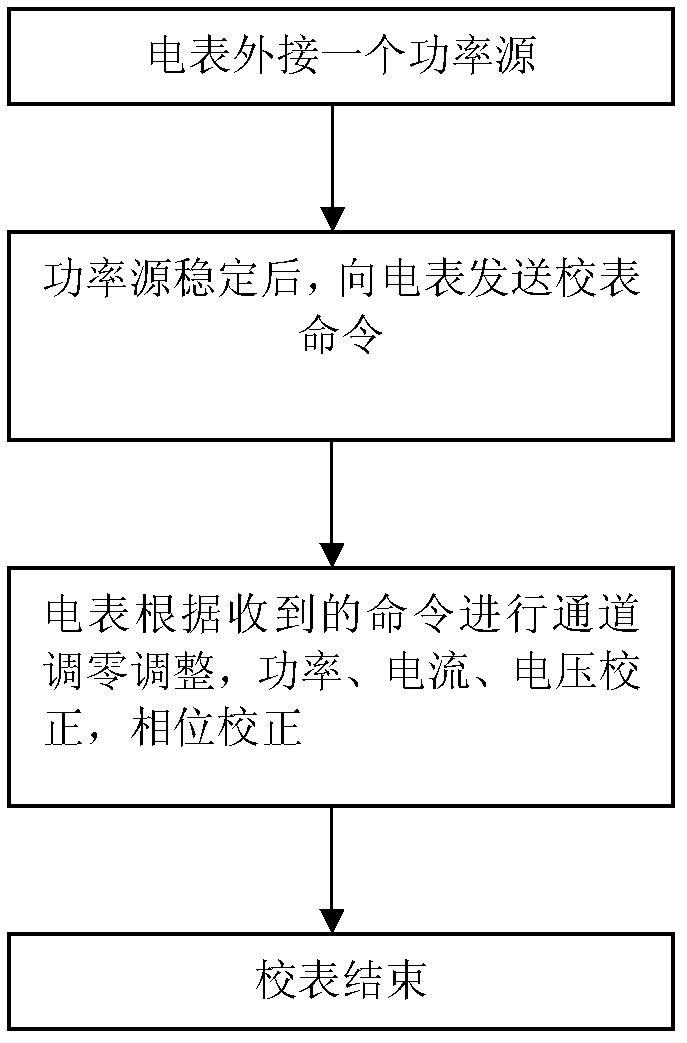

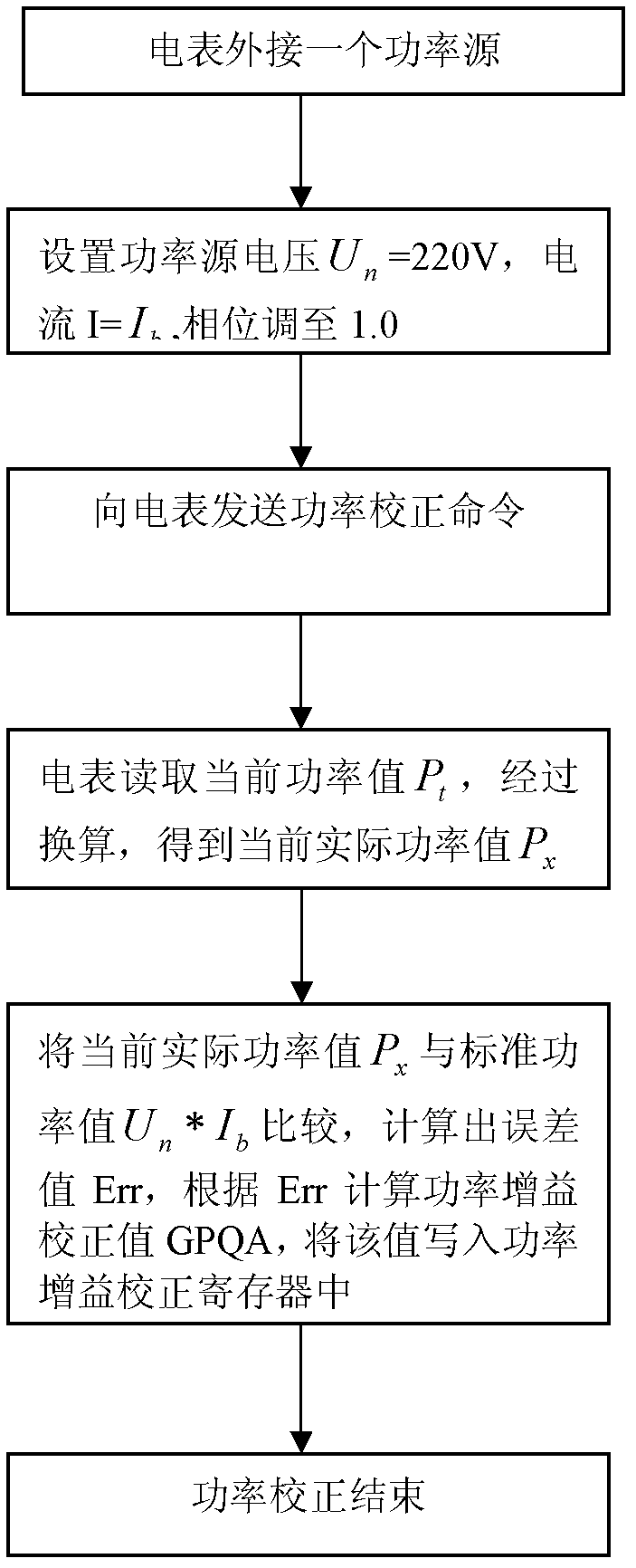

[0039] Such as figure 1 Shown, the table calibration step of the present invention is as follows:

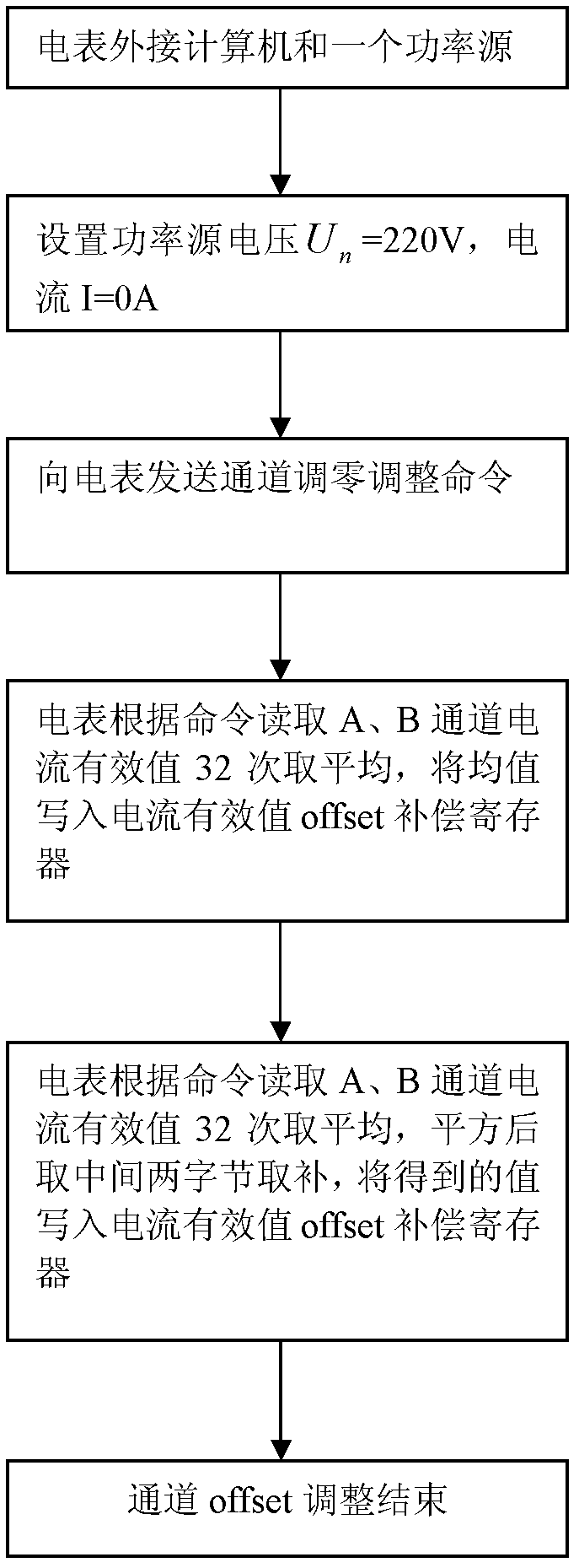

[0040] 1. Channel zero adjustment, the specific method is:

[0041] Step 1: Connect a power source externally to the meter, and set the parameter of the power source to voltage U n =220V, current I=0A;

[0042] Step 2: After the power source is stable, send a zeroing command to the meter, and the meter MCU accepts the command;

[0043] Step 3: The metering chip RN8209 in the meter reads the A and B channel current RMS values 32 times and takes the average to obtain the average value, writes the obtained average value into the current channel RMS register, and adjusts the channel current RMS value according to thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com