Implementation method of operation interface of automatic plant start-up &and shut-down system

A technology of control system and operation interface, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as poor logic applicability, large difference between APS functional design intention and actual operation effect, and reduction of operating personnel , to achieve control output optimization, simplify human-computer interaction design, and improve applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

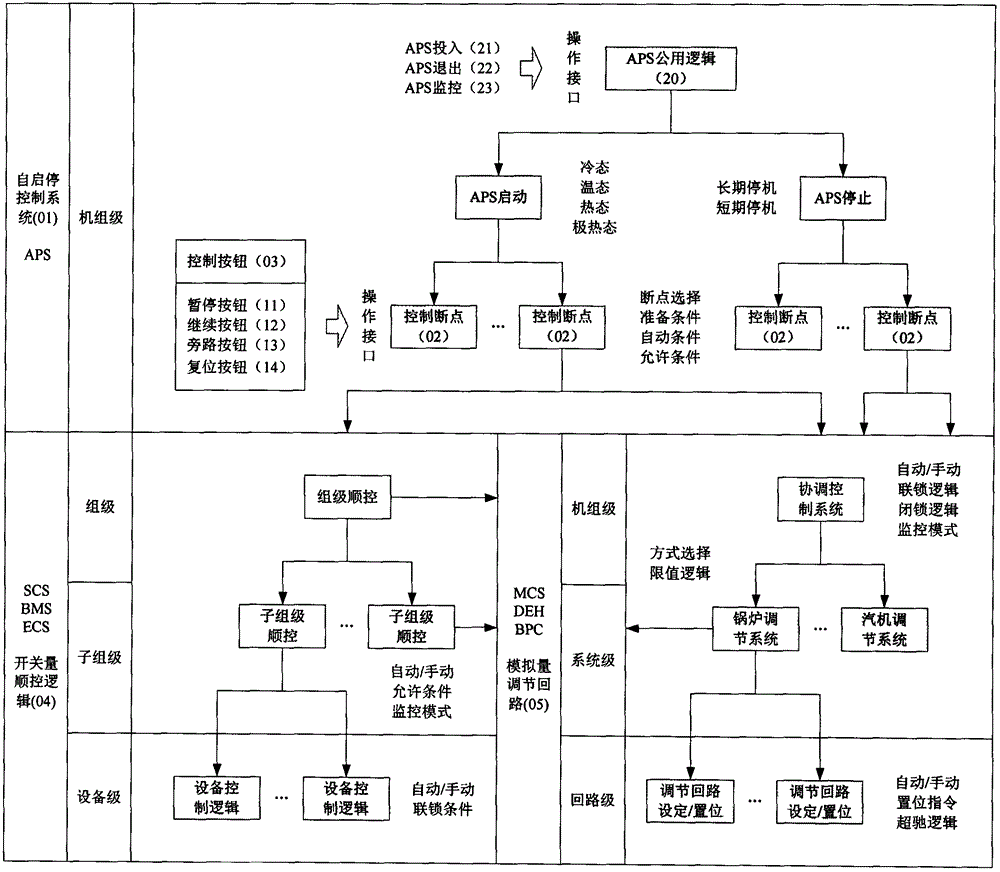

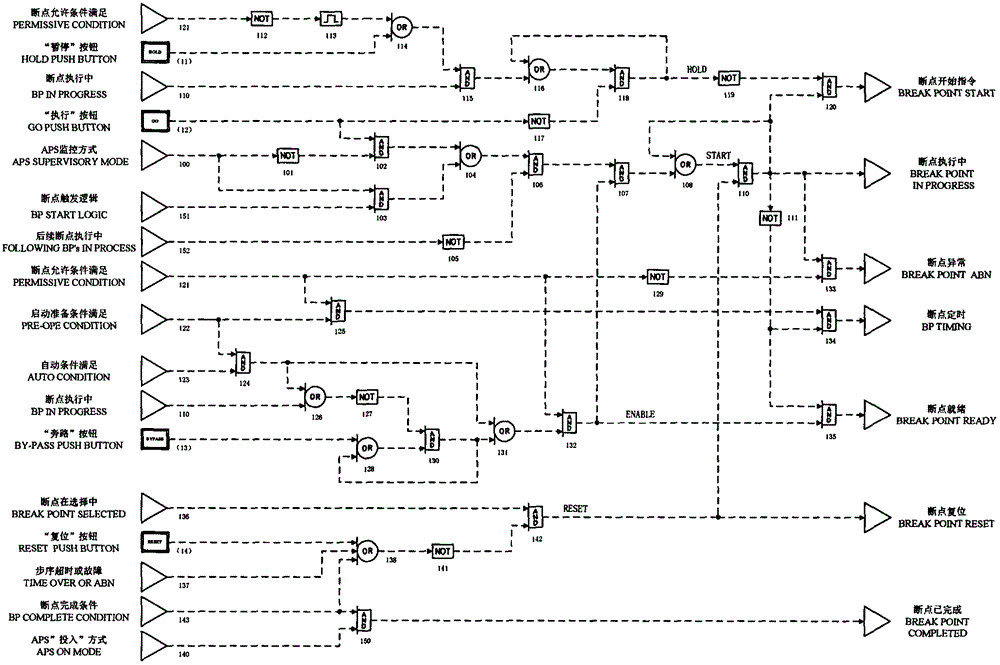

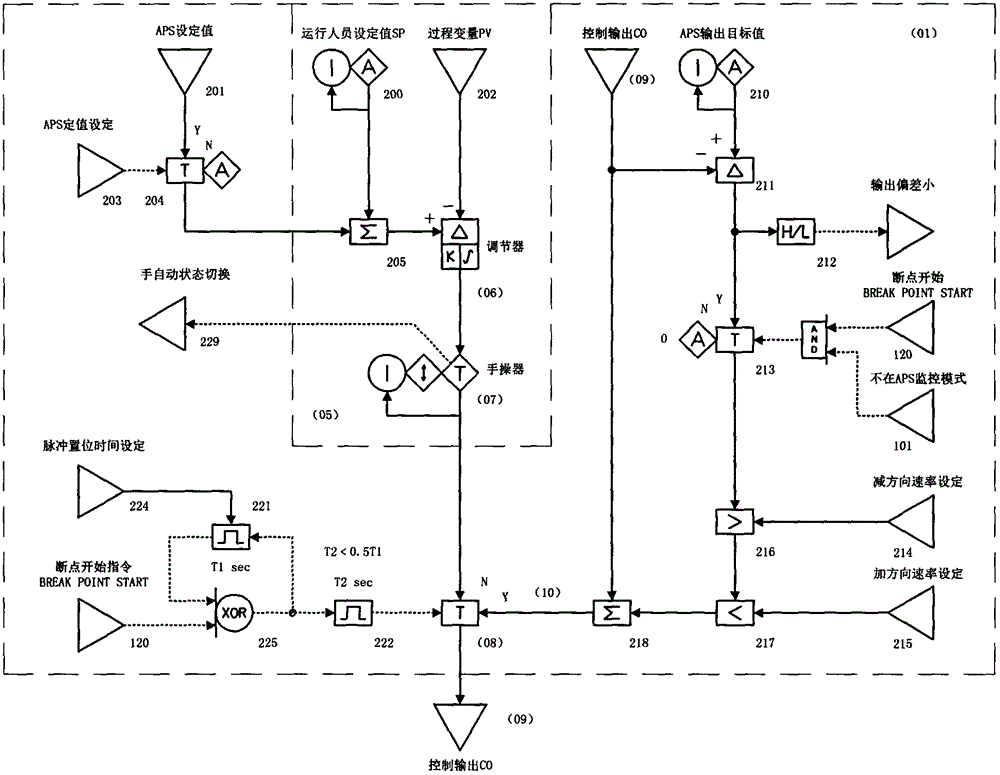

[0028] Attached below figure 1 ~ attached image 3 Let's describe in detail the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention and provides specific implementation methods and system structures, but the protection scope of the present invention is not limited to the following embodiments.

[0029] The method of the present invention is used to optimize the design of the unit self-starting and stopping control system of the first domestic 350MW full-combustion low calorific value gas tower once-through boiler-steam turbine generator set. The unit unit decentralized control system DCS and steam turbine control system of the embodiment TCS adopts the Ovation system of American Emerson Company and the T-3000 system of Siemens Company respectively. This embodiment adopts the method of the present invention to optimize and modify the originally designed APS control logic in the Ovation system, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com