Halbach array permanent magnetic efficient energy-saving textile motor

A high-efficiency energy-saving, array technology, applied in motor control, synchronous motor with stationary armature and rotating magnet, single motor speed/torque control, etc., can solve the problem that the accuracy is easily affected by ambient temperature, humidity, dust, vibration, The installation accuracy of the sensor is high, the system is susceptible to external interference and other problems, so as to save the mechanical sensor, improve the ability to resist irreversible demagnetization, and improve the effect of rapid response ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The Halbach array permanent magnet high-efficiency energy-saving textile motor of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

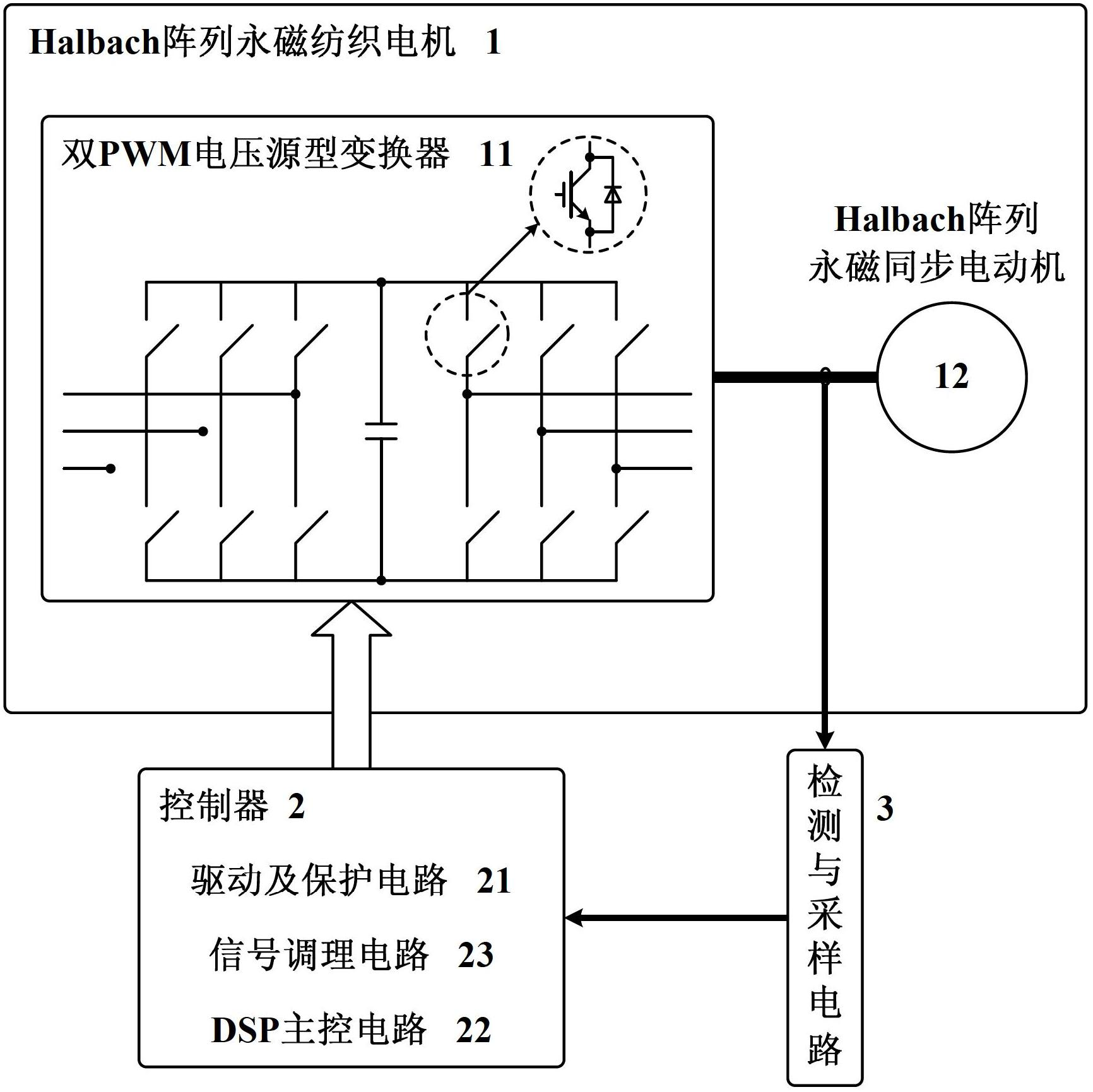

[0038] Such as figure 1 , figure 2As shown, the Halbach array permanent magnet high-efficiency energy-saving textile motor of the present invention includes: a Halbach array permanent magnet textile motor 1, a controller 2 and a detection and sampling circuit 3, and the Halbach array permanent magnet textile motor 1 is composed of a converter 11 It is integrated with the Halbach array permanent magnet synchronous motor 12, the output of the converter 11 is respectively connected to the Halbach array permanent magnet synchronous motor 12 and the detection and sampling circuit 3, and the output of the detection and sampling circuit 3 is connected to the controller 2, The controller 2 is connected to the converter 11 . The controller described in the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com