Starting detection device and starting method for permanent magnetic synchronous motor speed sensorless

A permanent magnet synchronous motor and speed sensorless technology, which is applied in the direction of measuring devices, control generators, instruments, etc., can solve the problems of mechanical transmission system power device damage, low motor capacity utilization, wind turbine vibration, etc., to ensure normal operation The effect of starting and service life, high utilization rate and high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

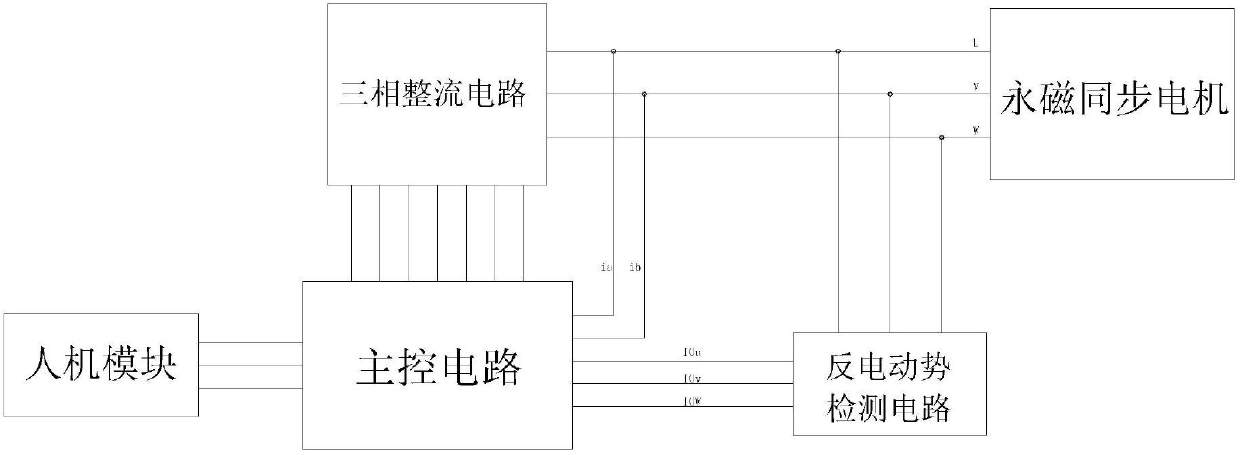

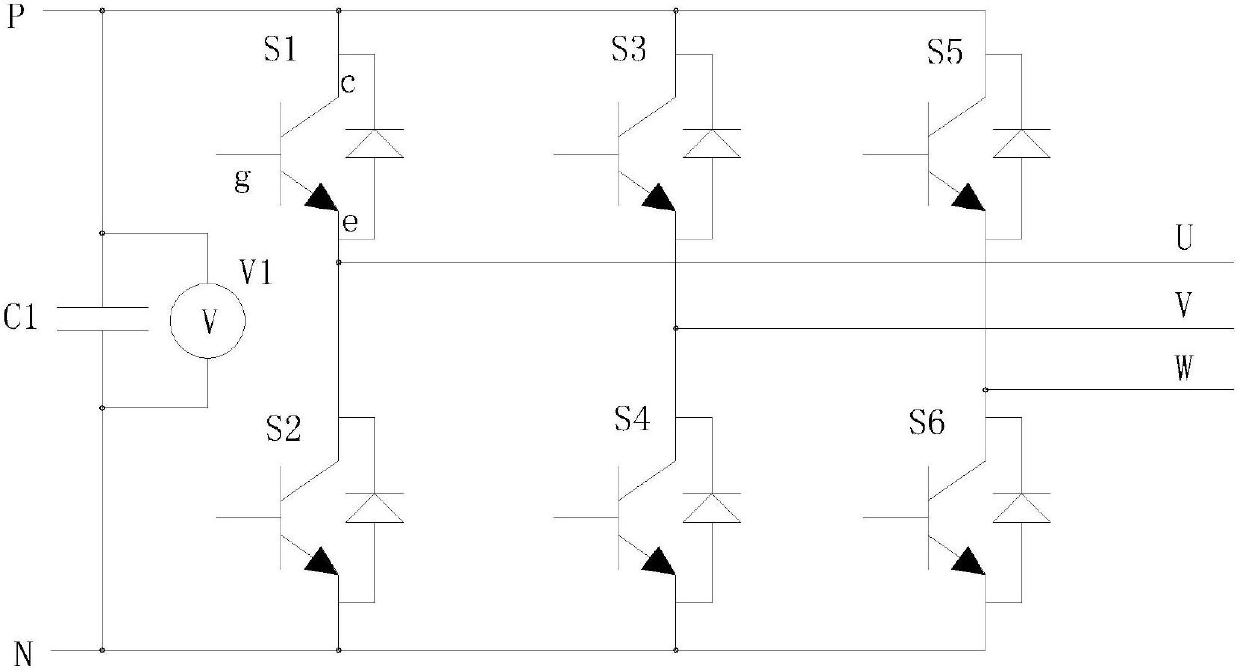

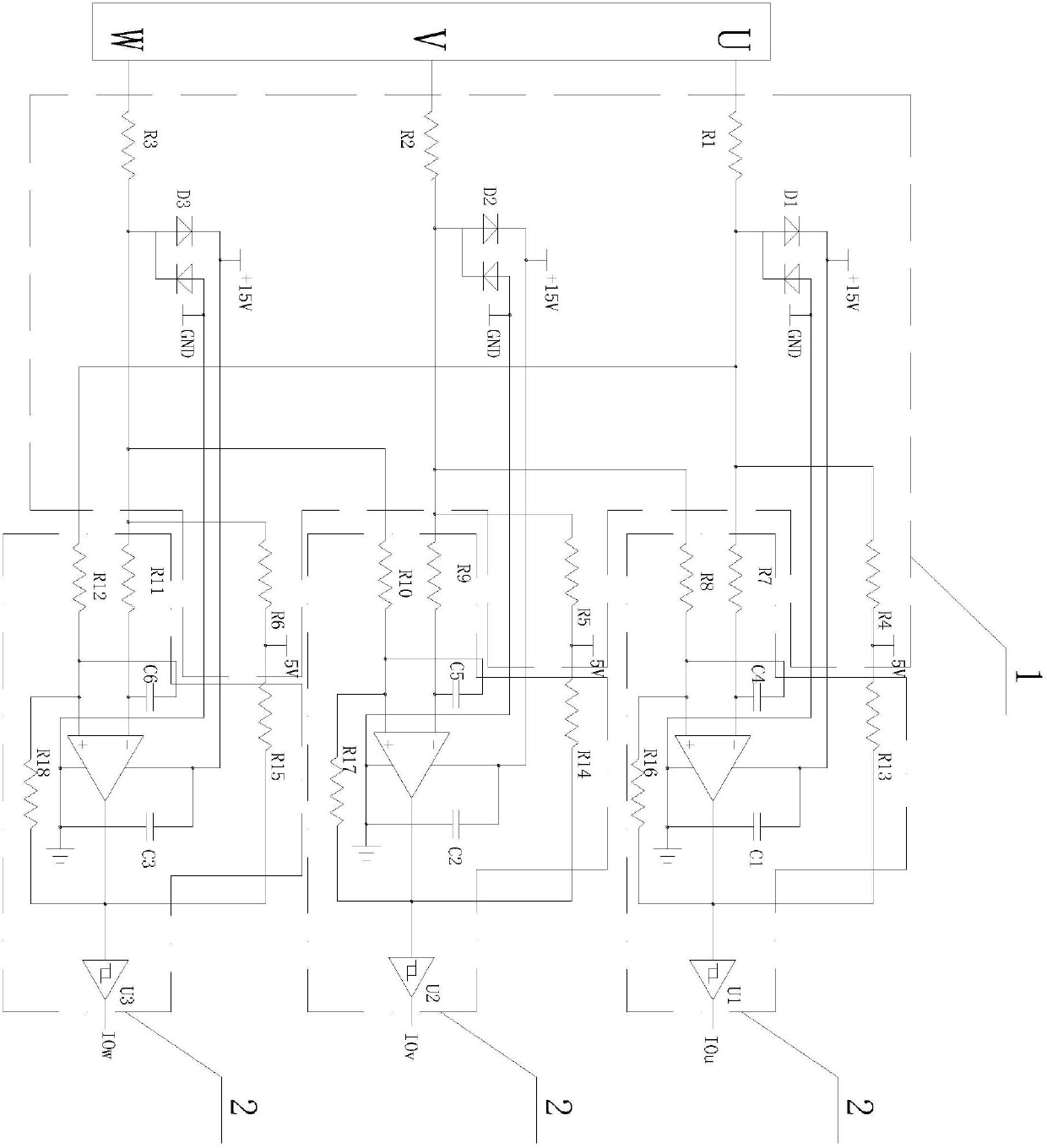

[0021] like figure 1 , figure 2 , image 3 As shown, the present invention is a start-up detection device for a permanent magnet synchronous motor without a speed sensor, including a three-phase rectifier circuit and a permanent magnet synchronous motor, and the permanent magnet synchronous motor and the three-phase rectifier circuit pass through U, V, W three road connection; the described starting detection device also includes a main control circuit, a man-machine module and a counter electromotive force detection circuit; the input terminal of the counter electromotive force detection circuit is connected with U, V and W of the permanent magnet synchronous motor in three ways, that is image 3 In U, V, W are respectively connected with U, V, W of the permanent magnet synchronous motor; image 3 IOu, IOv, IOw in the main control circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com