Vibration and airflow combined screening straightening-out mechanism

A combined and mobile mechanism technology, applied in horticulture, botany equipment and methods, gardening tools/equipment, etc., can solve the problems of no research reports, etc., and achieve the effect of stable working process, ingenious structural design, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

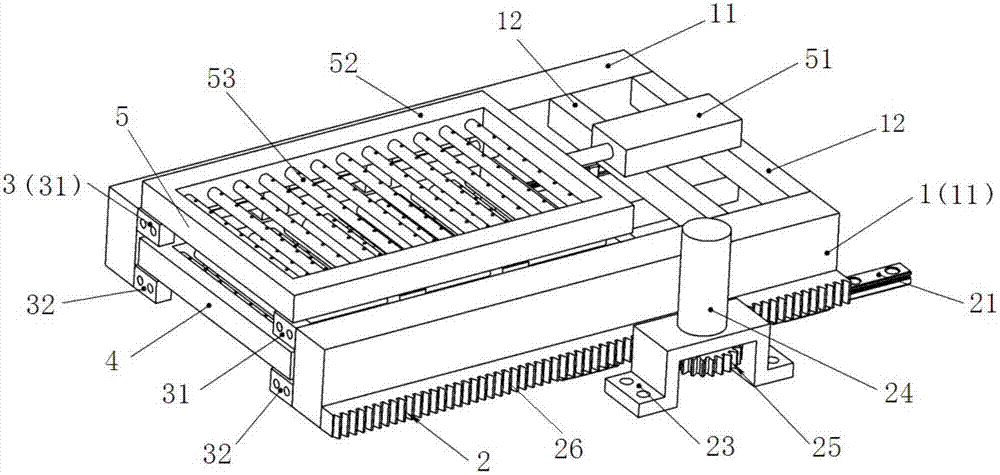

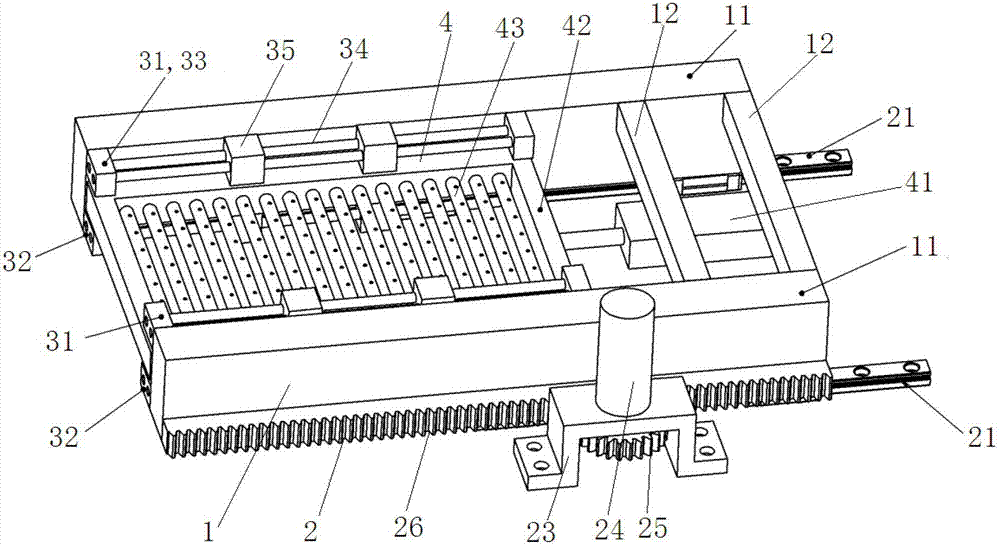

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a frame 1, a frame moving mechanism 2, a sieve body rail mechanism 3, a lower sieve body 4 and an upper sieve body 5.

[0019] Such as figure 1 , figure 2 As shown, the frame 1 of the present invention includes two side beams 11 , and two end beams 12 are arranged at intervals on the upper part of one end of the two side beams 11 .

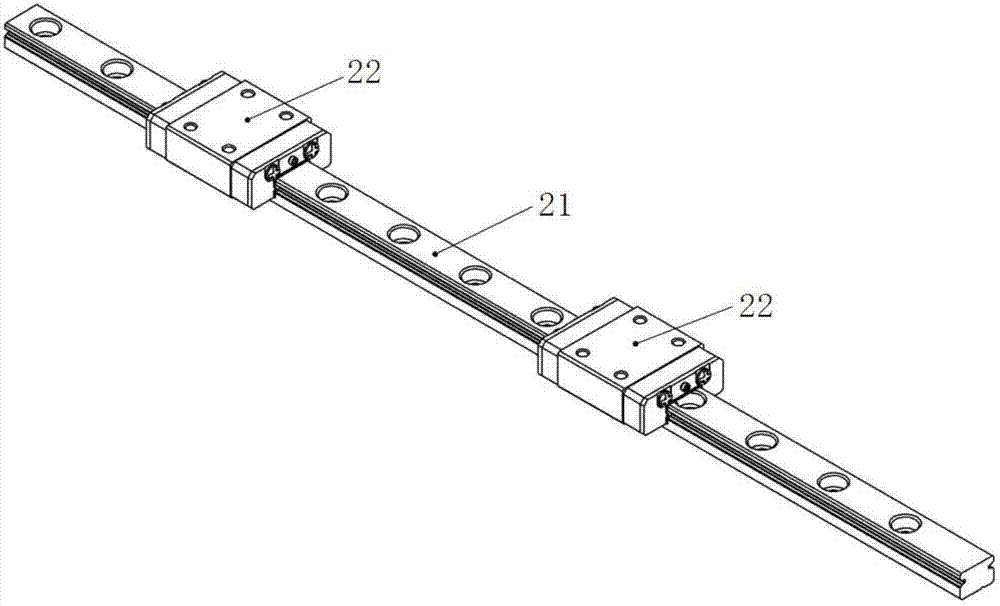

[0020] Such as Figure 1~3 As shown, the frame moving mechanism 2 of the present invention includes two general screen guide rails 21 fixed on the workbench by screws, and the two general screen guide rails 21 are respectively located under a side beam 11 correspondingly, and the two general screen guide rails 21 Two general sieve sliders 22 are slidably arranged at an even interval on the top, and the two general sieve sliders 22 on each g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com