Production technology of suckling pig nursing material

A production process and nursery feed technology, which is applied in the production process of suckling pig nursery feed, can solve the problems of uneven granulation, inability to effectively promote the growth of suckling pigs, and imprecise granules, so as to achieve the health of pigs and solve the weaning stress , high benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

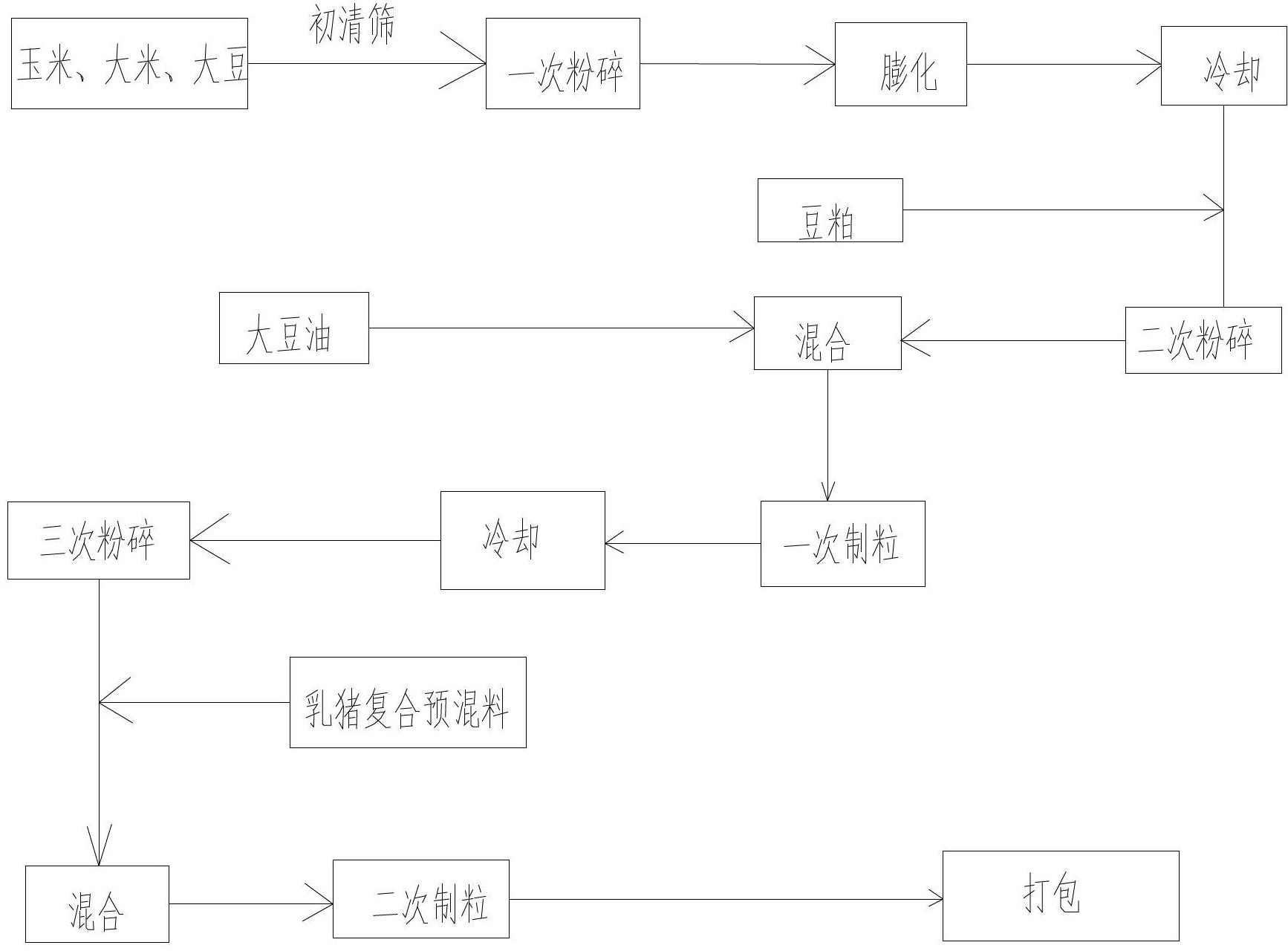

[0016] Such as figure 1 Shown, a kind of production technology of nursery feed for suckling pigs comprises the following steps:

[0017] (1) 200~210 parts of corn, 250~300 parts of rice, and 60~70 parts of soybeans are first cleaned and sieved, and then crushed once, and the crushed particle size is 2.0~2.3mm;

[0018] (2) Put the first crushed material into the expansion chamber for puffing, then cool it, mix the cooled material with soybean meal and then crush it again, the crushed particle size is 2.0~2.3mm;

[0019] (3), mixing soybean oil and the materials obtained by the secondary pulverization in the step (2) with 30-40 parts of fish meal, 5-10 parts of intestinal membrane protein powder, 40-50 parts of glucose, 10-13 parts of stone powder, 0.5~1 part of table salt, 0.5~0.8 part of choline chloride, 0.5~0.8 part of microencapsulated acidifier, 2~3 parts of lysine, 0.5~0.8 part of methionine and 0.1~0.2 part of antioxidant, then perform a granulation , the granulation ...

Embodiment 2

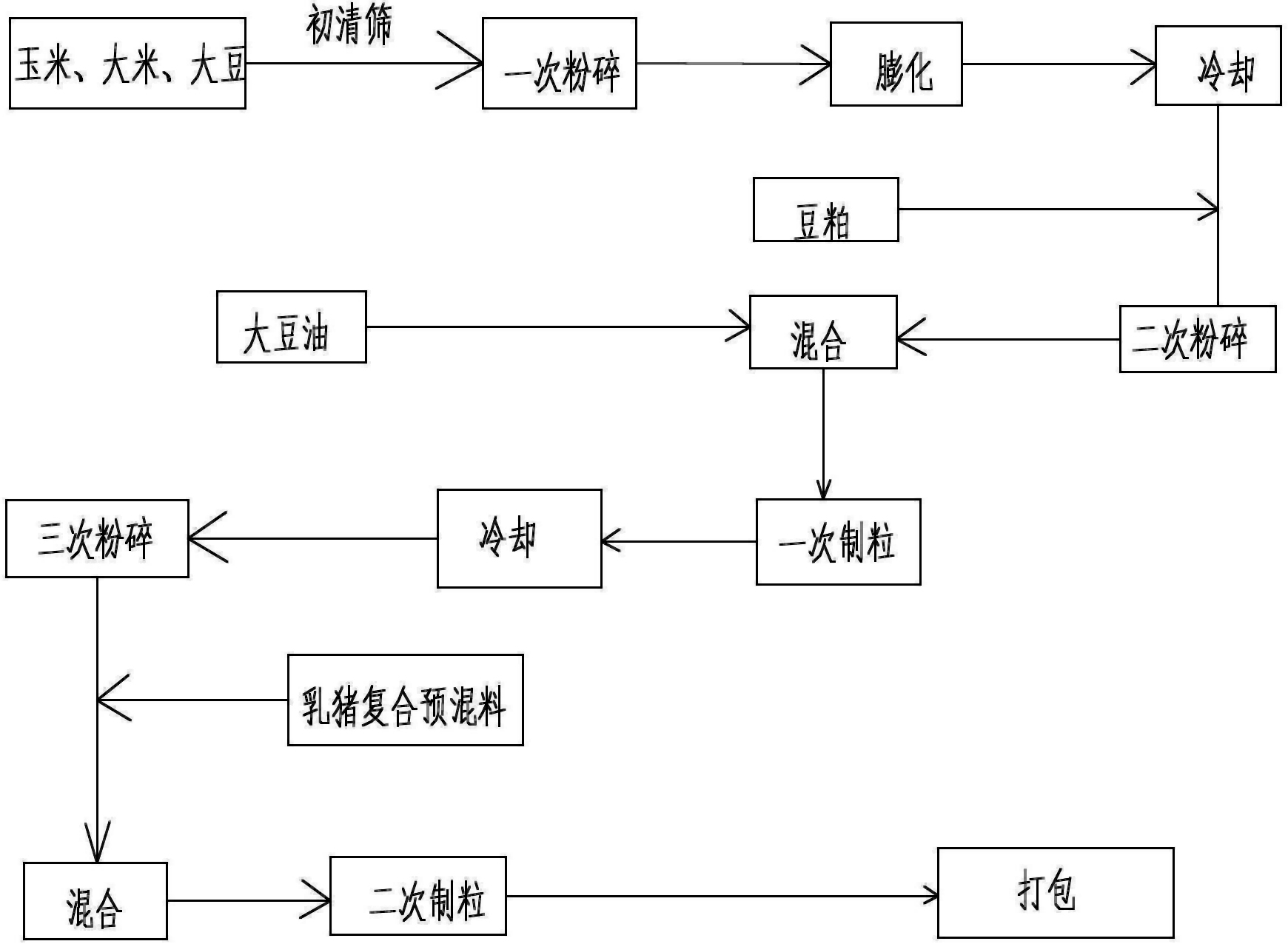

[0026] A production process for nursery feed for suckling pigs, comprising the following steps:

[0027] (1) 210~220 parts of corn, 300~400 parts of rice, and 70~80 parts of soybeans are first cleaned and sieved, and then crushed once, and the crushed particle size is 2.3~2.5mm;

[0028] (2) Put the first crushed material into the expansion chamber for puffing, then cool it, mix the cooled material with soybean meal and then crush it again, the crushed particle size is 2.3~2.5mm;

[0029] (3), mixing soybean oil and the materials obtained by the secondary pulverization in the step (2) with 40-50 parts of fish meal, 10-15 parts of intestinal membrane protein powder, 50-60 parts of glucose, 13-15 parts of stone powder, 1~2 parts of table salt, 0.8~2 parts of choline chloride, 0.8~2 parts of microencapsulated acidifier, 3~4 parts of lysine, 0.8~1 part of methionine and 0.2~0.4 parts of antioxidant, and then perform a granulation , the granulation temperature is ≥90°C, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com