SCR (selective catalytic reduction) denitration dedusting device

A technology of denitrification and dust removal and dust collector, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problem of increasing the power consumption and operating cost of induced draft fans, increasing the pressure head selection of boiler induced draft fans, and high temperature The complex structure of the cyclone separator and other problems achieve the effects of low additional cost, easy fabrication and installation, and reduced fly ash concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following non-limiting examples serve to illustrate the invention.

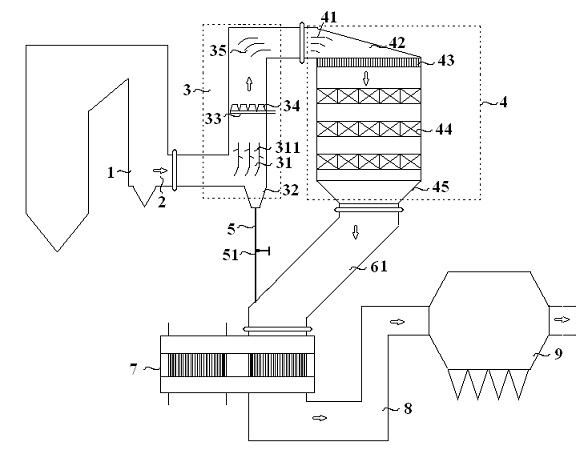

[0028] Such as image 3 As shown, the flue gas 2 of about 320-420°C flowing out from the outlet of the boiler economizer 1 enters the reactor inlet flue 3, and the upstream of the flue gas process of denitration and reducing agent injection in the reactor inlet flue 3 is from horizontal to vertical The bent 90° elbow (that is, the first 90° elbow in the figure) is provided with a dust removal guide device 31, and the flue gas passes through the dust removal guide device 31 to remove the ash and turn to the upward direction, and sprays with the reducing agent injection device 33 The incoming reducing agent ammonia is uniformly mixed by the reducing agent mixer 34 and then continues to move upward, and is guided by the second baffle 35 to enter the denitration reactor 4. The flue gas-ammonia mixture flows through the inlet baffle 41, the inlet cover 42, and uniformly passes through the catalyst layer 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com