Vertical rice polisher

A rice milling machine and rice milling technology applied in the field of vertical rice milling machines to achieve the effects of light weight, high precision and improved germ retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

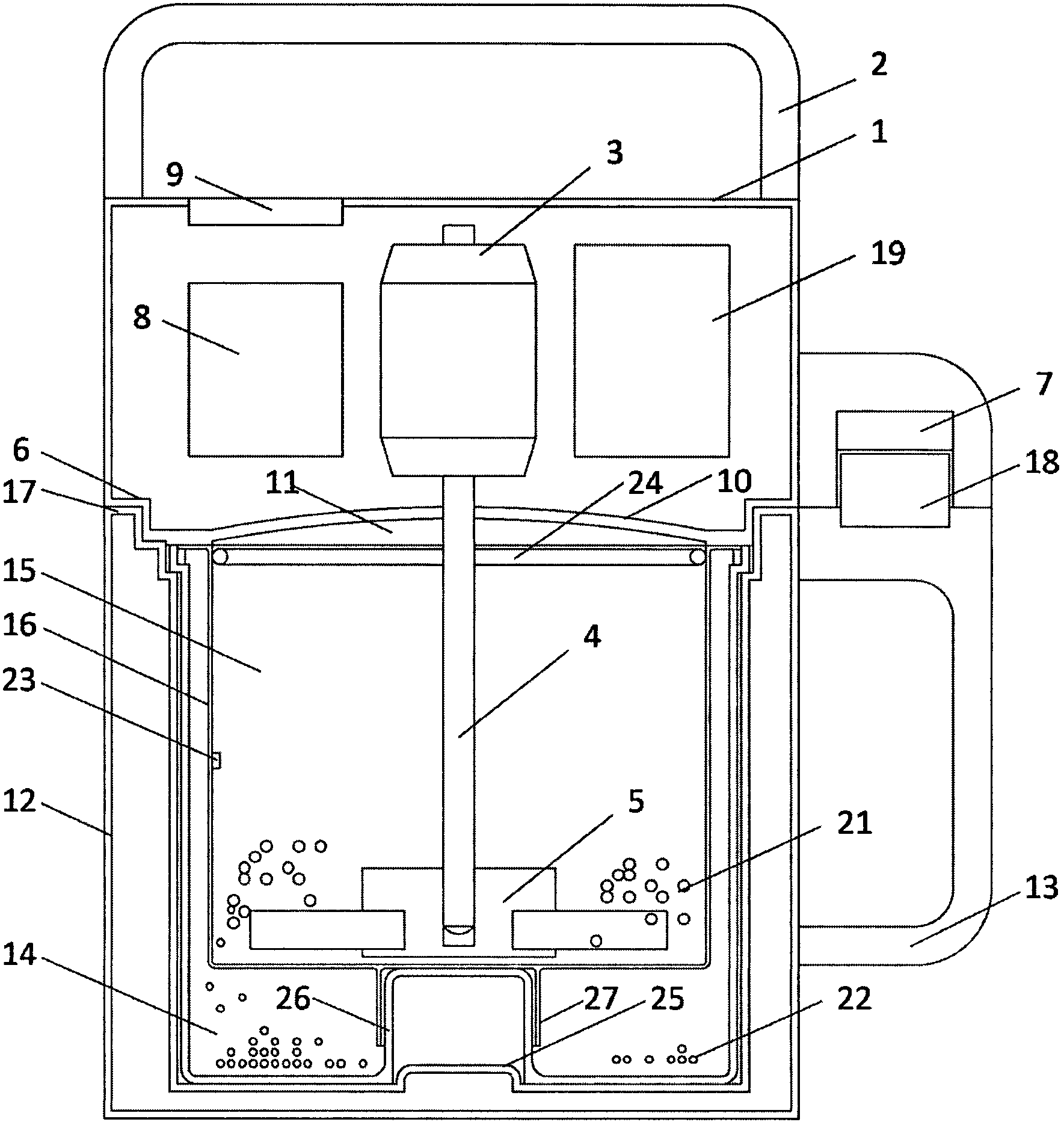

[0061] The rice polishing machine of the present embodiment is made up of three parts, the upper body of the rice polishing machine, the lower body of the rice polishing machine and the control system, as figure 1 As shown, the upper body of the rice polishing machine is located above the lower body of the rice polishing machine.

[0062] The upper body of the rice polishing machine is composed of an upper body shell 1, a motor 3, a transmission shaft 4, a processing impeller 5, an upper part of a sealer 6, an upper part of a power coupler 7, a control circuit 8, a control panel 9, and a top cover 10 of a rice polishing chamber.

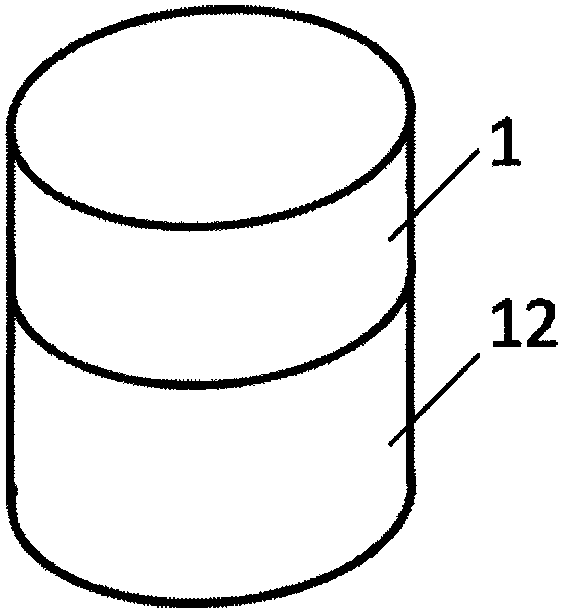

[0063] The upper body shell 1 is made of plastic, and the side circumference is metal, and the overall shape is as follows: figure 2 It is approximately cylindrical as shown; the top of the upper body shell 1 is connected with a grip handle 2, which is convenient for the user to hold; the upper surface of the upper body shell 1 is embedded with a co...

Embodiment 2

[0086] use image 3 This embodiment will be described. Compared with Embodiment 1, the upper body shell 1 and the lower body shell 12 of this embodiment adopt a roughly cubic structure, and the grasping handle 2 of the upper body of the rice polishing machine and the grasping handle 13 of the lower body of the rice polishing machine can still be combined together , and the plane of symmetry of the handle 2 and the handle 13 coincides with a certain plane of symmetry of the upper body and the lower body of the rice polishing machine.

Embodiment 3

[0088] Compared with Embodiment 1-2, the upper body shell 1 and the lower body shell 12 of this embodiment are made of plastic, including the gripping handle 2, upper surface, side surface and rice polishing room top cover 10 belonging to the upper body shell 1 part, The grasping handle 13, the side surface, the lower surface and the inner bag belonging to the lower body shell 12 are all made of plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com