High-efficiency wet straightening granulator

A technology of sizing machine and wet method, which is applied in the field of wet sizing devices, can solve the problems of unfavorable health of operators, difficulty in ensuring drug efficacy or nutrition, and difficulty in avoiding a large amount of dust, so as to avoid decomposition failure or nutrient loss, Avoid mutual sticking or caking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

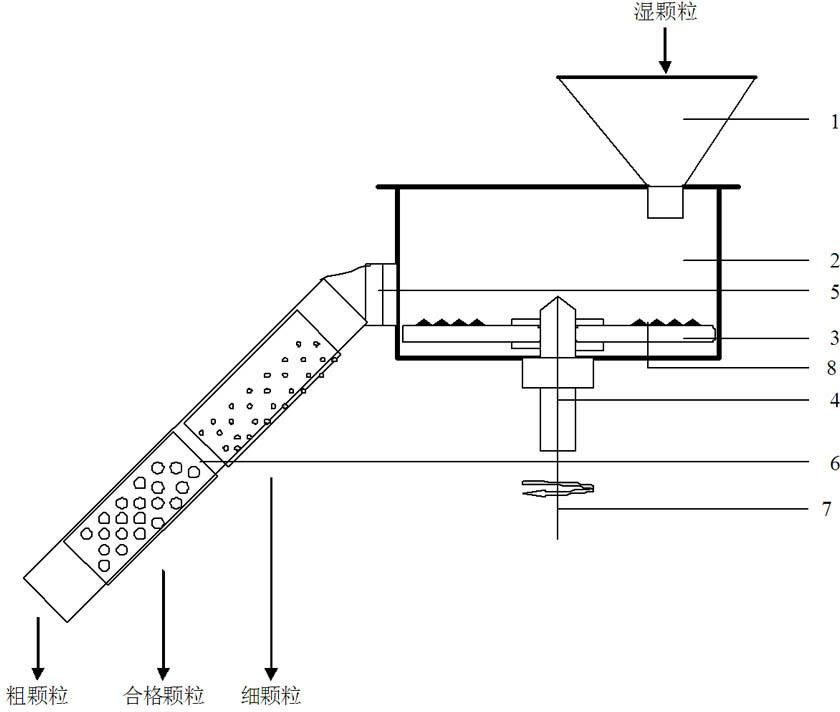

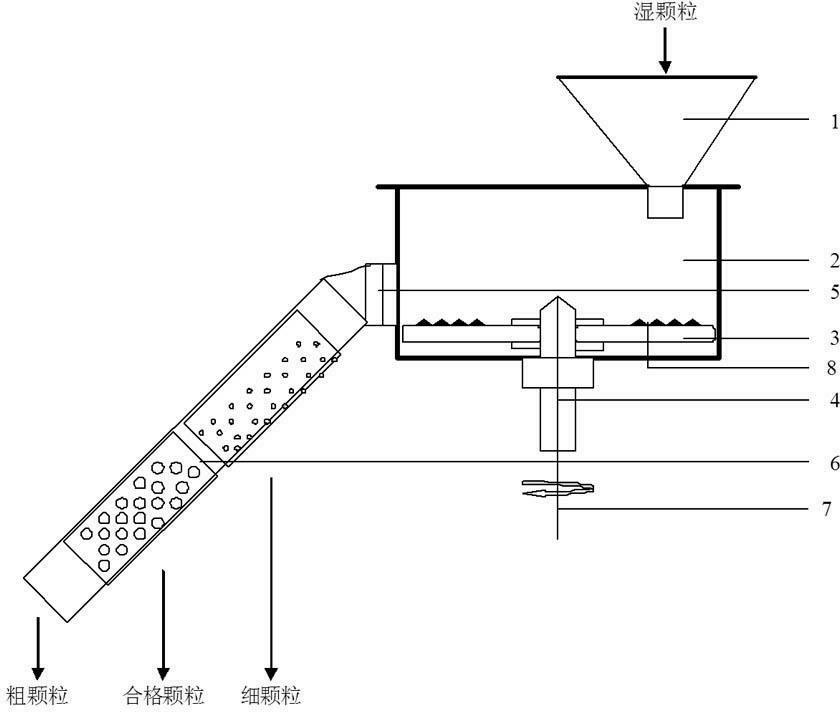

[0014] Such as figure 1 As shown, the high-efficiency wet granulator is composed of a hopper 1, a cylinder body 2, a toothed turntable 3, a rotating shaft 4, a discharge valve 5, a screening pipeline 6, and a motor 7. The hopper 1 is located in the cylinder body 2 On one side of the upper part, the bottom end of the other side of the cylinder 2 is connected with a discharge valve 5, and the discharge valve 5 is connected with the screening pipeline 6. The sieve holes on the sieve pipeline 6 are arranged in order from small to large, and the sieve holes The small end is located at the top of the screening pipeline, and the toothed turntable 3 is located at the bottom of the cylinder 2, and is connected to the motor 7 through the rotating shaft 4, and the motor 7 drives the rotating shaft 4 to rotate, and the rotating shaft 4 drives the toothed turntable 3 to rotate. There are evenly distributed triangular pyramids 8 on the tooth turntable 3 .

Embodiment 2

[0016] Such as figure 1 As shown, the high-efficiency wet granulator is composed of a hopper 1, a cylinder body 2, a toothed turntable 3, a rotating shaft 4, a discharge valve 5, a screening pipeline 6, and a motor 7. The hopper 1 is located in the cylinder body 2 On one side of the upper part, the bottom end of the other side of the cylinder 2 is connected with a discharge valve 5, and the discharge valve 5 is connected with the screening pipeline 6. The sieve holes on the sieve pipeline 6 are arranged in order from small to large, and the sieve holes The small end is located at the top of the screening pipeline, and the toothed turntable 3 is located at the bottom of the cylinder 2, and is connected to the motor 7 through the rotating shaft 4, and the motor 7 drives the rotating shaft 4 to rotate, and the rotating shaft 4 drives the toothed turntable 3 to rotate. There are quadrangular pyramids 8 evenly distributed on the tooth turntable 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com