Method for producing extruded polystyrene foam products by carbon dioxide foaming agent

A carbon dioxide and polystyrene technology, which is applied in the field of producing polystyrene extruded foam products by using carbon dioxide foaming agent, can solve the problems of dangerous use of alkane foaming agent, difficult injection, serious pollution, etc., and achieves physical properties. And the effect of stable chemical properties, extremely low water absorption, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

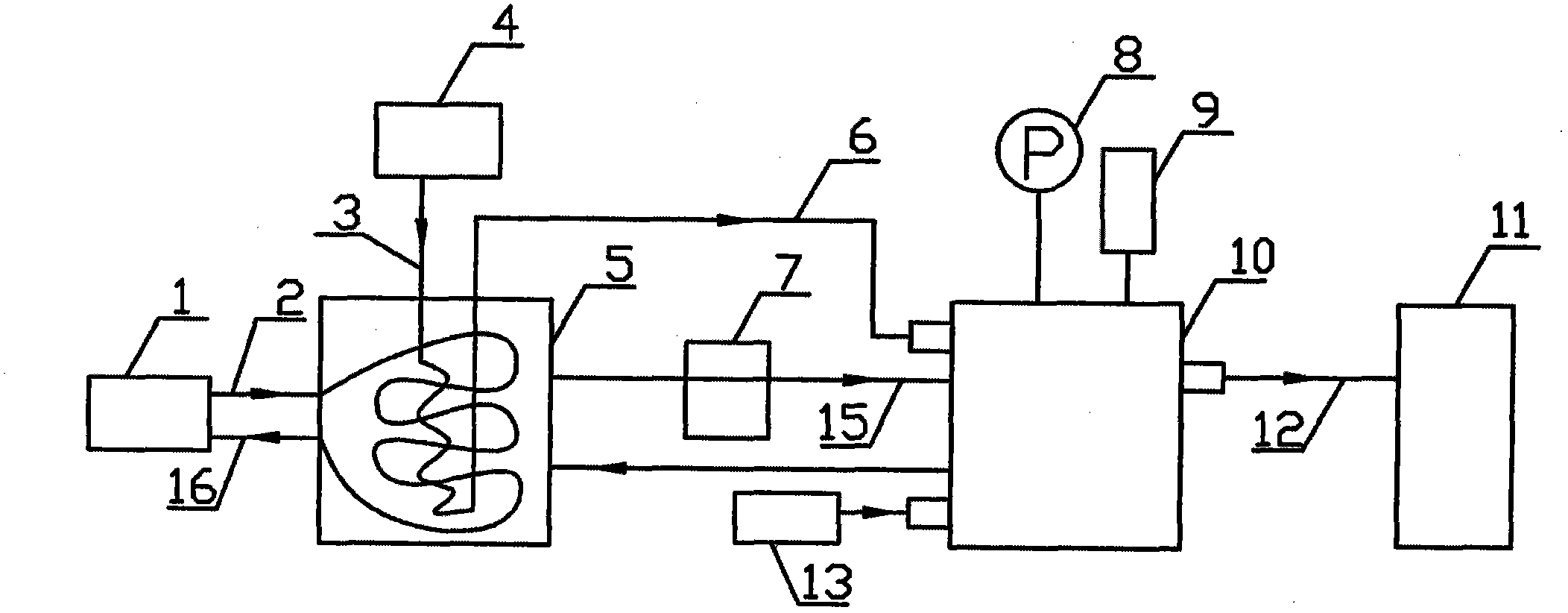

[0029] Embodiment 1: as figure 1 As shown, the injection device is a special injection device for carbon dioxide blowing agent, and the injection device is a special injection device for carbon dioxide blowing agent, including a carbon dioxide storage device 4, a high-pressure pumping device 10, a carbon dioxide storage device 4 and a high-pressure pumping device 10 Through pipeline communication, the high-pressure pumping device 10 is connected with the gas injection port of the plastic extruder 11 through the output pipeline D12, and the pipeline communication between the carbon dioxide storage device 4 and the high-pressure pumping device 10 is provided with a carbon dioxide gas-liquid conversion device. The gas-liquid conversion device includes a compressor 1, a constant temperature tank 5 and a circulation pump 7; the output end of the carbon dioxide storage device 4 is connected to the constant temperature tank 5 through the input pipeline A3, and then connected to the h...

Embodiment 2

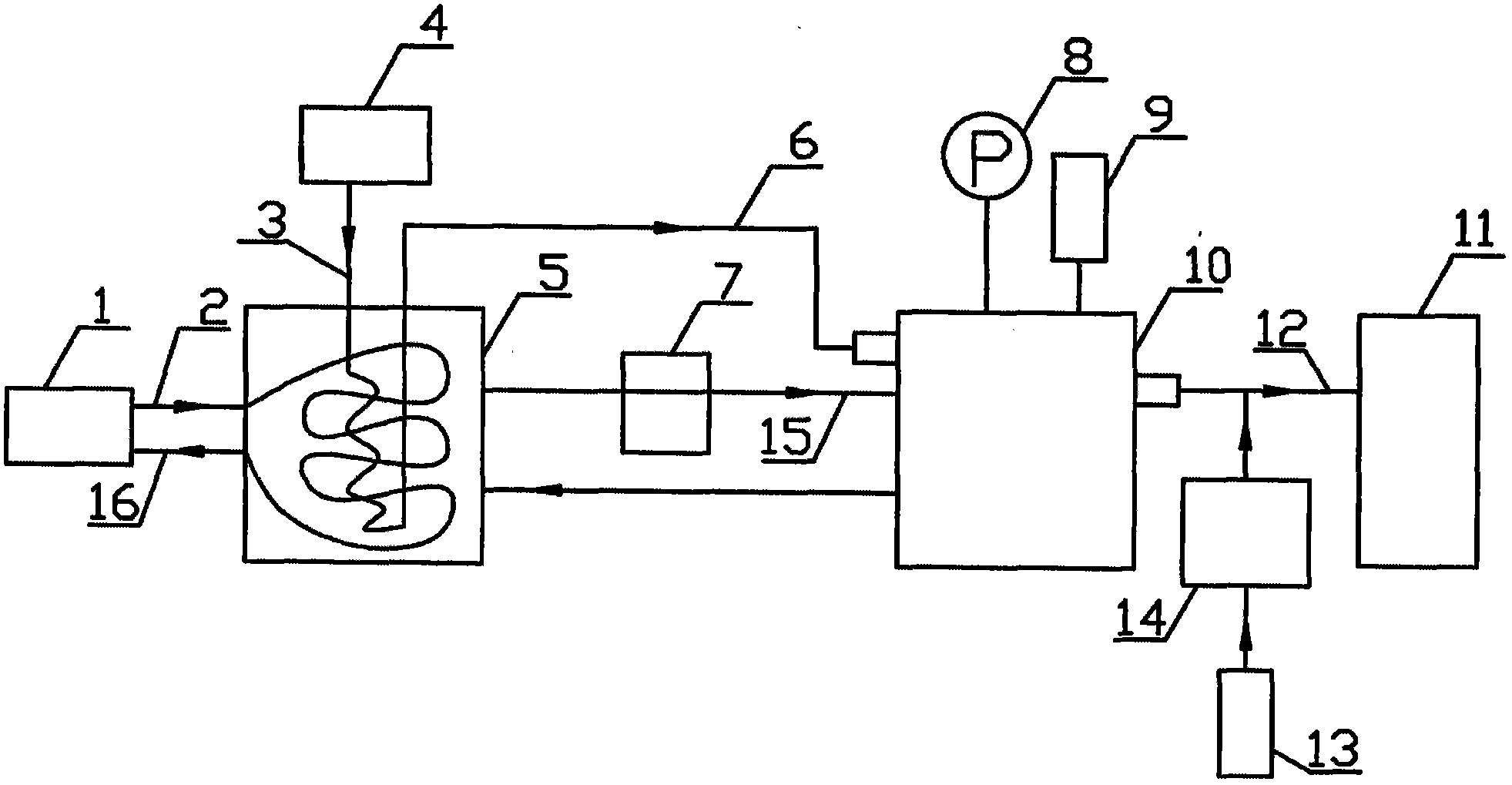

[0032] Embodiment 2: as figure 2 Shown is basically the same as in Example 1, the difference is that the structure of the special injection device for carbon dioxide blowing agent and the injection method of foaming aid are different. The agent pumping device 14 is connected to the auxiliary agent storage device 13 . The carbon dioxide foaming agent becomes liquid through the carbon dioxide gas-liquid conversion device and enters the high-pressure pumping device 10 through the pipeline, and then injects into the output pipeline D12. Other additives first pass through the additive storage device 13 before entering the auxiliary pumping device 14 , and then injected into the output pipeline D12, so that the carbon dioxide blowing agent and other additives are mixed in the output pipeline D12 and then enter the extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com