Rough stone block reinforcement adhesive and using method thereof

A technology for reinforcing glue and blocks, which is applied in the field of reinforcing stone blocks, can solve the problems of insufficient injection pressure, poor environmental protection performance, easy yellowing, etc., and achieves the effect of easy disassembly and firm fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

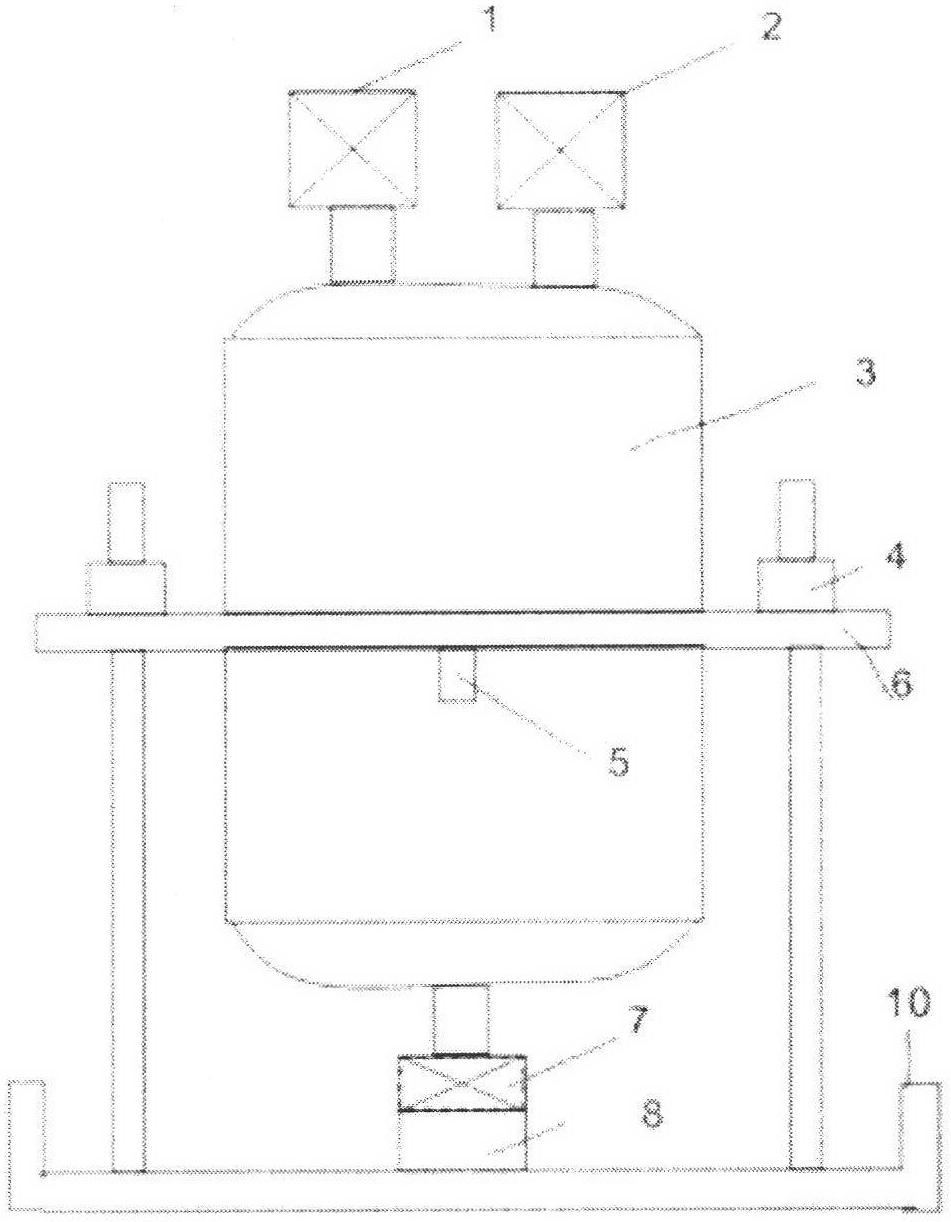

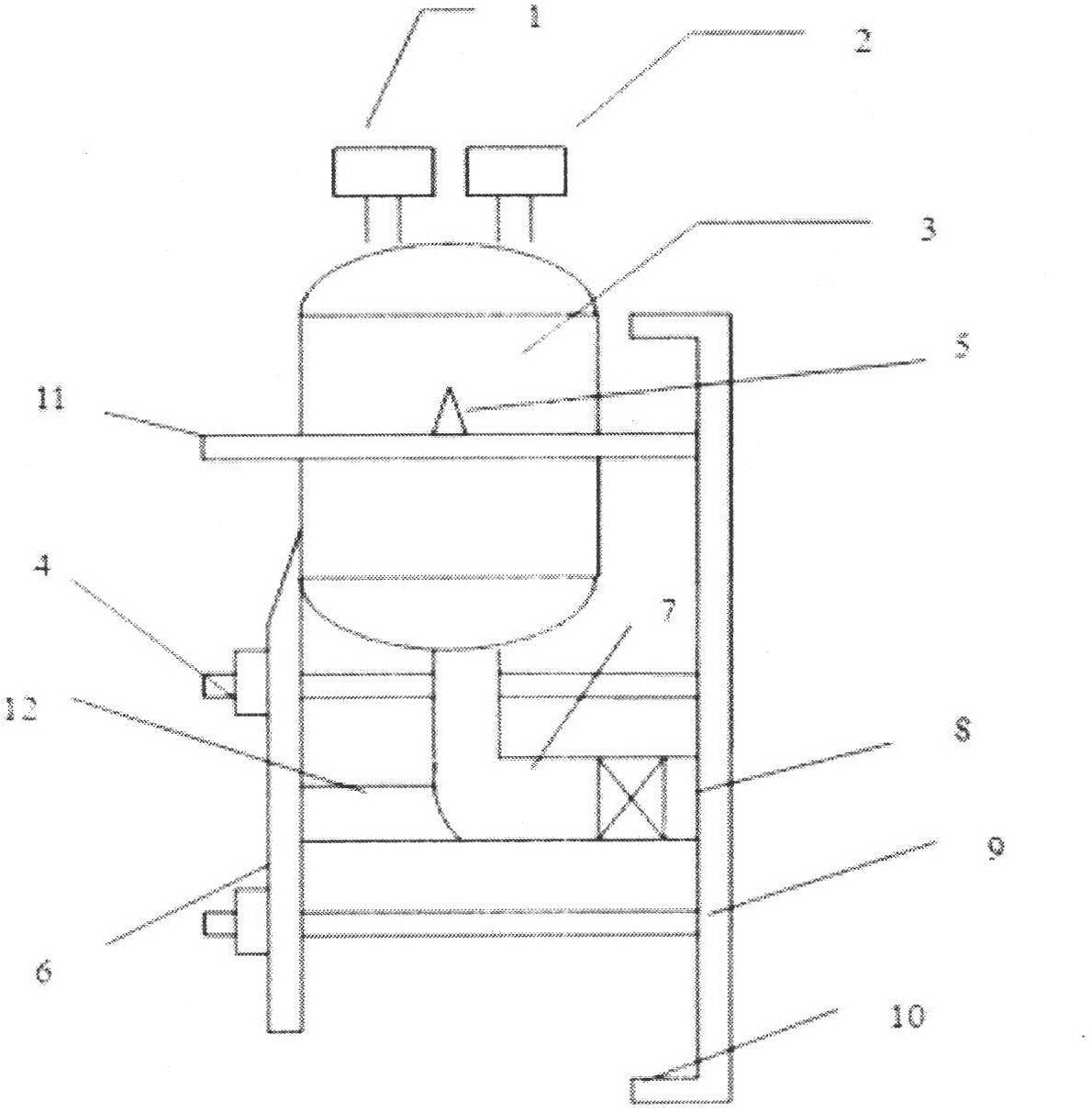

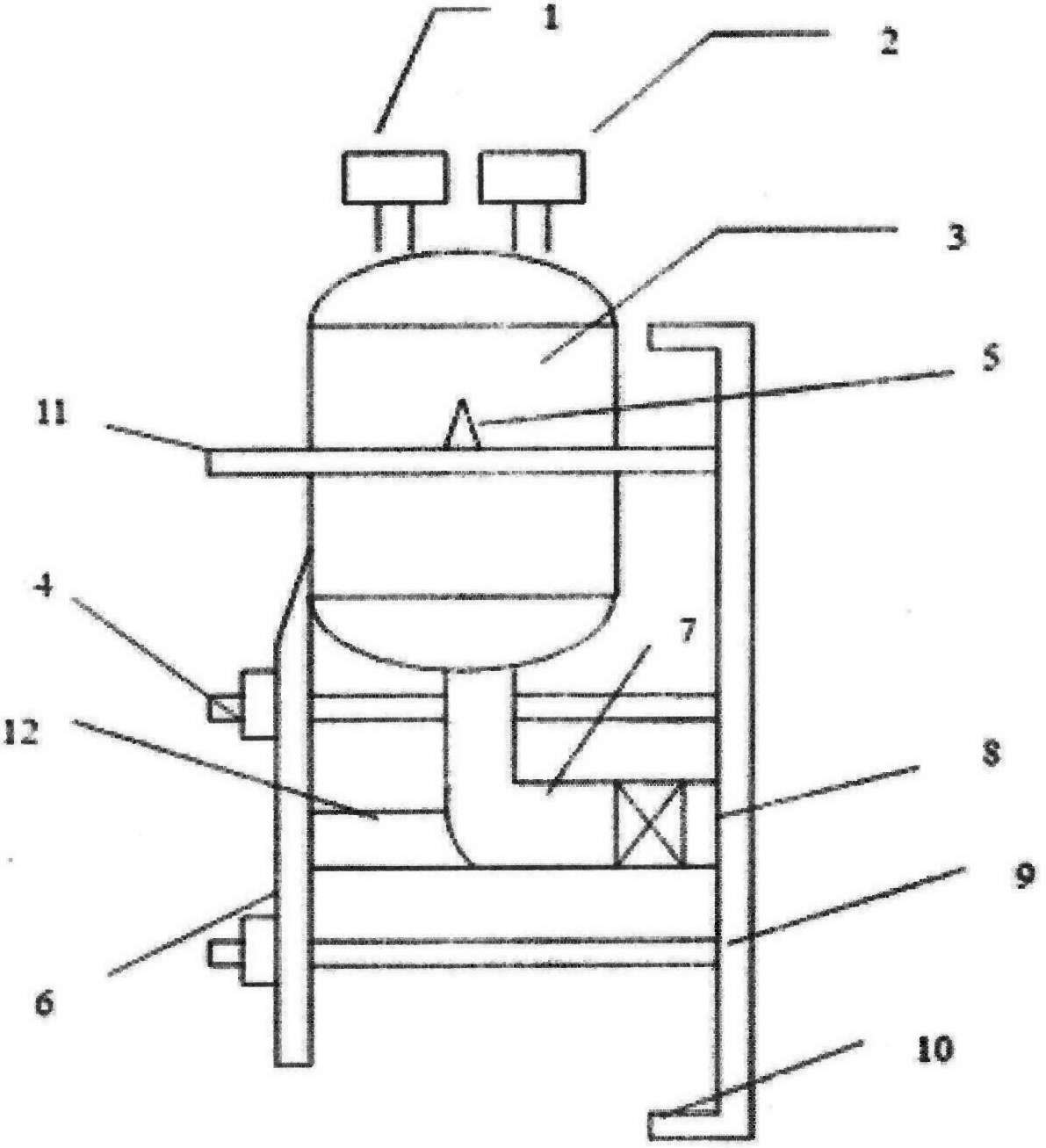

Method used

Image

Examples

Embodiment 1

[0050]1 Add bisphenol A epoxy resin E-51 70.3kg into the reactor, start stirring, then add bisphenol F epoxy resin F-51 12kg, o-cresyl glycidyl ether 12.8kg, bisphenol A 4kg, ultraviolet absorber UV-11 0.3kg, wetting agent CA-165 0.6kg, heat up to 62°C, keep warm for 1.5 hours, cool down to 30°C, stop stirring, filter through a 200-mesh sieve to obtain component A of the reinforcing glue of the present invention.

[0051] 2 Add 31.6kg of methylcyclopentyldiamine to the reaction kettle, start stirring, and then add 25kg of m-xylylenediamine, 16kg of polyetheramine D-400, 17kg of ketimine TZ-550, anti-yellowing additive V85- P 0.4kg, coupling agent KH-550 2kg, curing accelerator N,N-methyldipropylenetriamine 6kg, benzyl alcohol 2kg, heat up to 70°C, keep warm for 2 hours, cool down to 30°C, stop stirring, and Filter through a 200-mesh sieve to obtain component B of the reinforcing glue of the present invention.

[0052] 3 Weigh 10kg of component A, 3kg of component B, mix well,...

Embodiment 2

[0054] When preparing component A of the reinforcing glue, the wetting agent was changed to 0.6 kg of SP-978, and the rest of the conditions were the same as in Example 1.

[0055] When preparing component B of the reinforcing adhesive, the ketimine was changed to TZ-600 17kg, the curing accelerator was changed to DMP-302kg, N,N--methyldipropylenetriamine 4kg, and the anti-yellowing additive was changed to V76- P 0.2kg, V85-P 0.2kg all the other conditions are the same as embodiment 1.

[0056] Weigh 10kg of component A, 2.5kg of component B, mix well, and measure the viscosity of 185mpa.s at 25°C. After the sample is cured at room temperature for 7 days, the compressive shear strength of the stone / stone is 14.5Mpa. According to the use method of the present invention, the stone After the block was reinforced at 10°C for 7 days, the slices were normal, the reinforcement glue had good permeability, the curing was complete, and there was no obvious yellowing.

Embodiment 3

[0058] When preparing component A, the wetting agent was changed to CA-165 0.3kg, SP-978 0.3kg, and the rest were the same as in Example 1.

[0059] When preparing component B, the methylcyclopentadiamine was changed to 32.6kg, the curing accelerator was changed to 5kg of 399-1 accelerator, and the rest were the same as in Example 1.

[0060] Weigh 10kg of component A and 2.4kg of component B, mix well, and measure the viscosity at 25°C to be 134mpa.s. After the sample is cured at room temperature for 7 days, the stone / stone compressive shear strength is 17MPa. According to the method of the present invention, the marble blocks are reinforced at an ambient temperature of 35°C. After 7 days of curing at 35°C, the blocks are sliced normally, the reinforcing glue has good permeability in the cracks, the curing is complete, and there is no obvious yellowing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com