Method for extracting hydroxyl sanshool from zanthoxylum oil

A technology of hydroxyl sanshool and prickly ash oil, which is applied in the field of extracting bioactive components, and achieves the effects of convenient operation, simple pretreatment and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

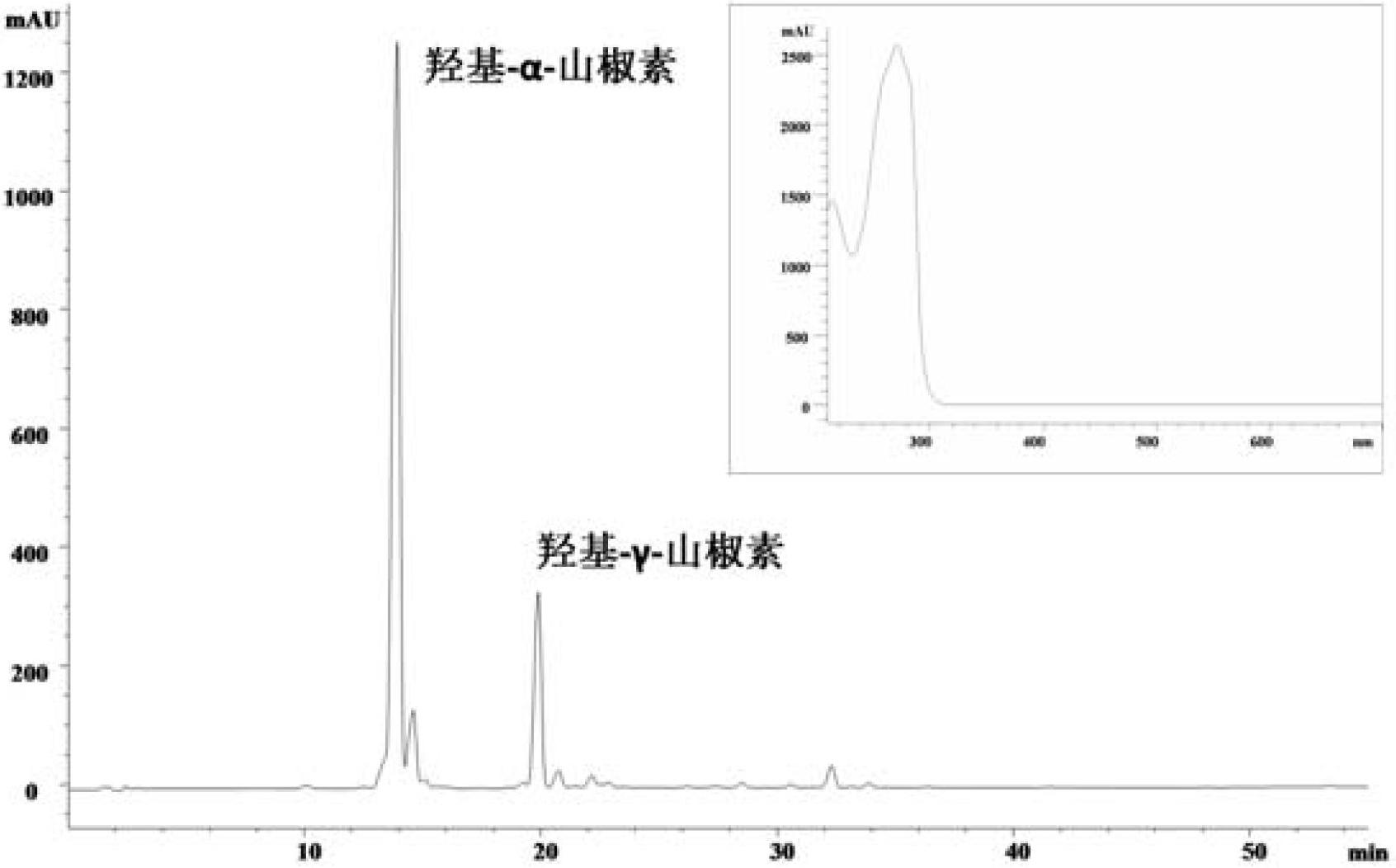

Image

Examples

Embodiment 1

[0022] Add 20 ml of Zanthoxylum bungeanum oil into methanol at a volume ratio of 1:20, mechanically shake at room temperature for 20 minutes, then ultrasonically shake at an ultrasonic frequency of 35Hz for 5 minutes, and then centrifuge the extract at a speed of 2500r / min for 10 minutes ; Take supernatant, pass Al 2 o 3 After the polyphenols were removed by the chromatographic column, it was frozen at -20°C in the dark for 12 hours; the extract was subjected to rotary evaporation at ≤40°C to obtain 0.95 g of the concentrate.

[0023] First dissolve the concentrate with 3 ml of 70% (v / v) methanol, and load the sample according to the mass ratio of the sample to the silica gel column at 1:40, and then use 70% (v / v) methanol as the eluent at an elution flow rate of Perform isocratic elution at 0.5ml / min, and collect the eluate in 120 ml aliquots, and combine with thin-layer chromatography. Under the ultraviolet light of 254 nm, the second group with obvious purple spots appears...

Embodiment 2

[0028] Add 30 ml of Zanthoxylum bungeanum oil into methanol at a volume ratio of 1:25, first shake mechanically at room temperature for 25 minutes, then ultrasonically shake at an ultrasonic frequency of 45 Hz for 8 minutes, and then centrifuge the extract at a speed of 2800 r / min for 12 minutes; Take supernatant, pass Al 2 o 3 After the polyphenols were removed by the chromatographic column, it was frozen at -20°C in the dark for 15 hours; the extract was subjected to rotary evaporation at ≤40°C to obtain 1.275 g of the concentrate.

[0029] First dissolve the concentrate with 3.5 ml of 75% (v / v) methanol, and load the sample according to the mass ratio of the sample to the silica gel column at 1:45, and then use 75% (v / v) methanol as the eluent at an elution flow rate of The isocratic elution was performed at 1ml / min, and the eluate was collected in 100ml aliquots according to the collection volume of each part, and combined with thin layer chromatography, the second compon...

Embodiment 3

[0034]Add 40 ml of Zanthoxylum bungeanum oil into methanol at a volume ratio of 1:30, mechanically shake at room temperature for 30 minutes, then ultrasonically shake at an ultrasonic frequency of 55 Hz for 10 minutes, and then centrifuge the extract at a speed of 3000 r / min for 15 minutes; Supernatant, over Al 2 o 3 After the polyphenols were removed by the chromatographic column, it was frozen below -20°C in the dark for 18 hours; the extract was subjected to rotary evaporation at ≤40°C to obtain 1.901 g of a concentrate.

[0035] First dissolve the concentrate with 4 ml of 80% (v / v) methanol, and load the sample according to the mass ratio of the sample to the silica gel column at 1:50, and then use 80% (v / v) methanol as the eluent to elute at a flow rate of 1.5 ml / min for isocratic elution, and the eluate was collected in 80ml aliquots according to the collection volume of each part, and combined with thin layer chromatography, the second component with obvious purple spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com