Heat stabilizer composition of high-pressure hydrogenated cycloalkyl lubricating oil, preparation method thereof, and application thereof

A naphthenic lubricating oil, high-pressure hydrogenation technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problem of poor thermal stability of base oil, achieve the effect of preventing oxidation reaction and enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

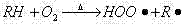

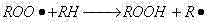

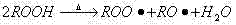

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A high-pressure hydrogenated naphthenic lubricating oil heat stabilizer composition, a mixture of antioxidant 2,5-di-tert-butylhydroquinone and antioxidant 1010 and a chelating agent three [2,4-di tert-butylphenyl] phenyl phosphite composition;

[0039] Calculated by mass percentage, wherein the total content of the mixture of antioxidant 2,5-di-tertbutylhydroquinone and antioxidant 1010 in a high-pressure hydrogenated naphthenic oil heat stabilizer composition is 80%, and in the mixture of the antioxidant 2,5-di-tert-butyl hydroquinone and the antioxidant 1010, calculated by mass ratio, that is, the antioxidant 2,5-di-tert-butyl hydroquinone Hydroquinone: Antioxidant 1010 is 2:1;

[0040] The content of the tris[2,4-di-tert-butylphenyl]phenylphosphite chelating agent in a high-pressure hydrogenated naphthenic oil heat stabilizer composition is 20%.

[0041] The preparation method of above-mentioned a kind of high-pressure hydrogenation cycloalkyl lubricating oil heat...

Embodiment 2

[0044] A high-pressure hydrogenated naphthenic lubricating oil heat stabilizer composition, a mixture of antioxidant 2,5-di-tert-butylhydroquinone and antioxidant 1010 and a chelating agent three [2,4-di tert-butylphenyl] phenyl phosphite composition;

[0045] Calculated by mass percentage, wherein the total content of the mixture of antioxidant 2,5-di-tertbutyl hydroquinone and antioxidant 1010 in a high-pressure hydrogenated naphthenic oil heat stabilizer composition is 80%, and in the mixture of the antioxidant 2,5-di-tert-butyl hydroquinone and the antioxidant 1010, calculated by mass ratio, that is, the antioxidant 2,5-di-tert-butyl hydroquinone Hydroquinone: Antioxidant 1010 is 3:1;

[0046] The content of the tris[2,4-di-tert-butylphenyl]phenylphosphite chelating agent in a high-pressure hydrogenated naphthenic oil heat stabilizer composition is 20%.

[0047] The preparation method of above-mentioned a kind of high-pressure hydrogenation cycloalkyl lubricating oil hea...

Embodiment 3

[0050] A high-pressure hydrogenated naphthenic lubricating oil heat stabilizer composition, a mixture of antioxidant 2,5-di-tert-butylhydroquinone and antioxidant 1010 and a chelating agent three [2,4-di tert-butylphenyl] phenyl phosphite composition;

[0051] Calculated by mass percentage, wherein the total content of the mixture of antioxidant 2,5-di-tertbutylhydroquinone and antioxidant 1010 in a high-pressure hydrogenated naphthenic oil heat stabilizer composition is 90%, and in the mixture of the antioxidant 2,5-di-tert-butyl hydroquinone and the antioxidant 1010, calculated by mass ratio, that is, the antioxidant 2,5-di-tert-butyl hydroquinone Hydroquinone: Antioxidant 1010 is 2:1;

[0052] The content of the tris[2,4-di-tert-butylphenyl]phenylphosphite chelating agent in a high-pressure hydrogenated cycloalkyl lubricating oil thermal stabilizer composition is 10%.

[0053] The preparation method of above-mentioned a kind of high-pressure hydrogenation cycloalkyl l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com