Copper-molybdenum disulfide self-lubricating conductive coating and preparation method thereof

A technology of conductive coating and molybdenum disulfide, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problems that the vacuum electric sliding copper-molybdenum disulfide coating method and technology have not been reported yet. Achieve good anti-friction lubrication, reduce wear and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

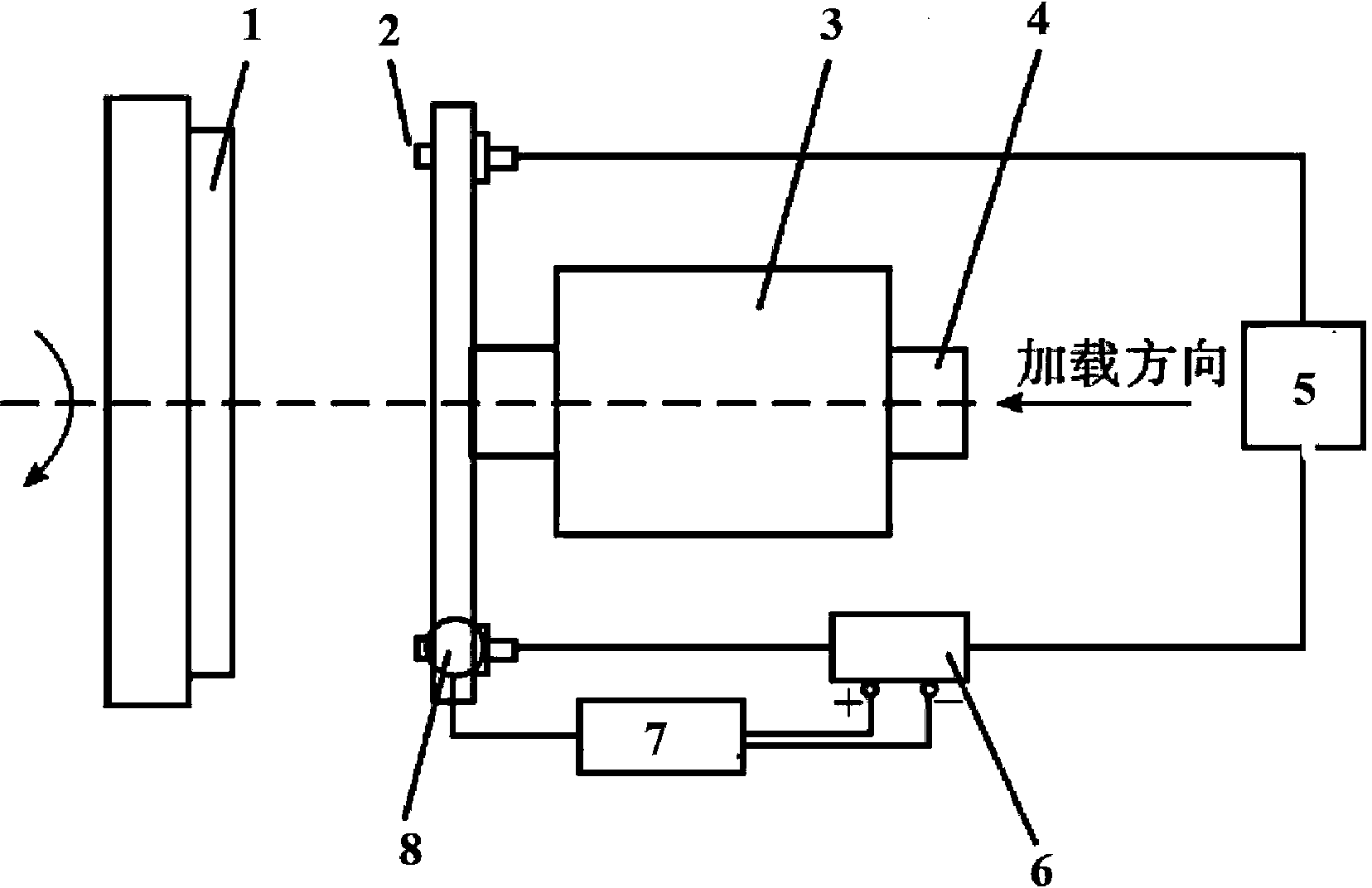

Method used

Image

Examples

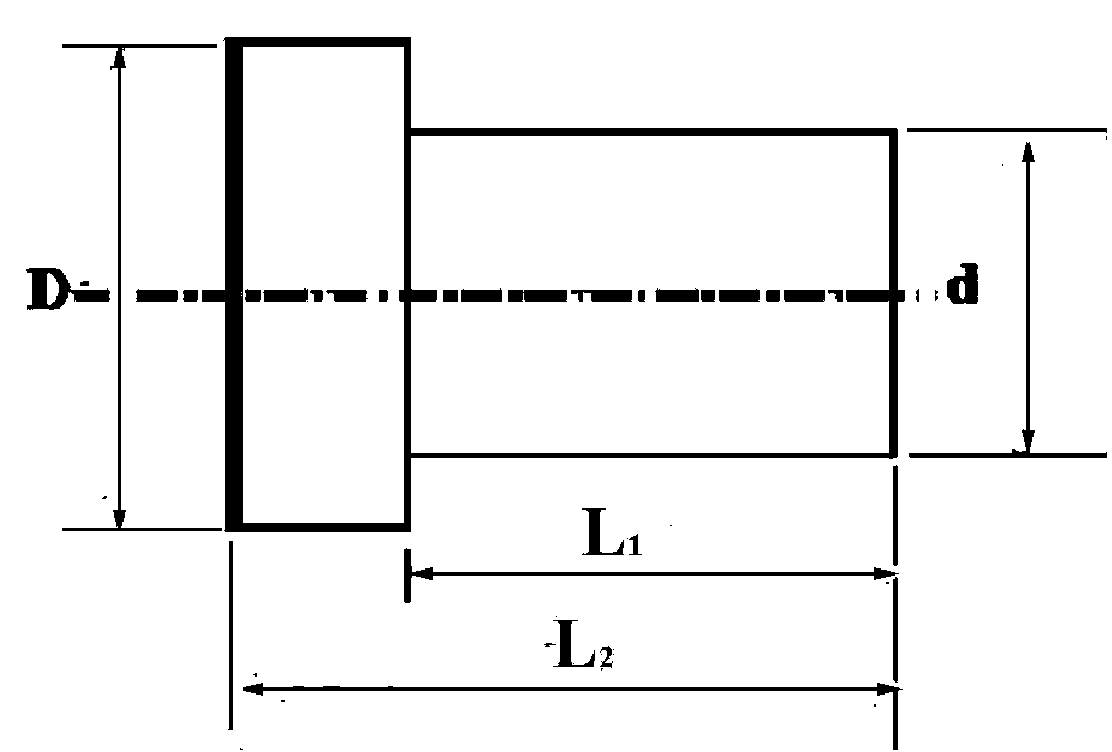

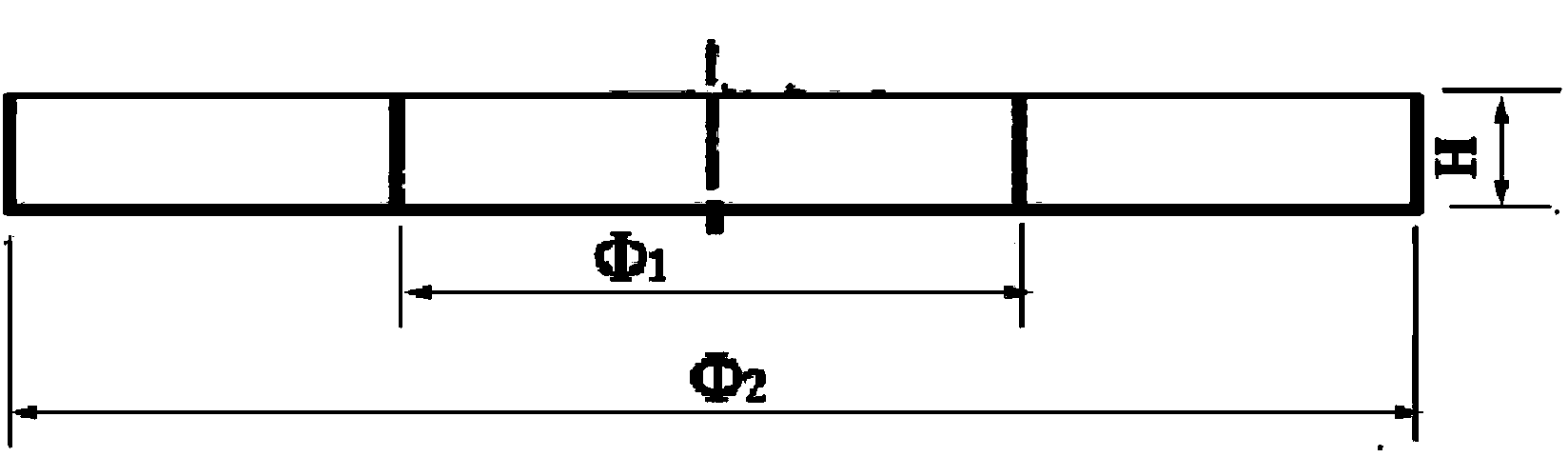

Embodiment 1

[0058] Atmospheric plasma spraying powder is 10mass.%MoS 2 , 90mass.% Cu powder, spraying substrate is LY12 aluminum alloy, the substrate is cleaned, degreased and sandblasted. The spraying parameters of the coating are set as: power 22kw, H 2 The flow rate is 0 SLPM, the Ar flow rate is 50 SLPM, the powder feeding rate is 50 g / min, and the spraying distance is 100 mm. The copper-molybdenum disulfide self-lubricating coating was obtained after 40 cycles of spraying at startup, with a thickness of about 250 μm.

[0059] Using the PPMS-9 comprehensive physical performance testing system, the electrical conductivity of the coating is about 10.8×10 -8 Ω m; the vacuum friction coefficient measured by the UMT-2 friction equipment of the US CETR company is about 0.06, and the wear rate is about (6.7±0.65)×10 -4 mg / m, compared with the pure copper bulk material (the vacuum average friction coefficient is about 0.75), the friction and wear properties of the copper-molybdenum disulfi...

Embodiment 2

[0061] Atmospheric plasma spraying powder is 10mass.%MoS 2 , 90mass.% Cu powder, the substrate for spraying is 316 stainless steel, and the substrate is cleaned, degreased and sandblasted. The spraying parameters of the coating are set as: power 22kw, H 2 The flow rate is 2 SLPM, the Ar flow rate is 50 SLPM, the powder feeding rate is 50 g / min, and the spraying distance is 110mm. The copper-molybdenum disulfide self-lubricating coating was obtained after 40 cycles of spraying at startup, and the product was removed for storage.

[0062] The conductivity of the coating is about 7.8×10 -8 Ω·m;, the friction coefficient under vacuum is about 0.07, and the wear rate is about (7.5±0.82)×10 -4 mg / m, the friction and wear performance of the composite coating has been improved.

[0063] Using PPMS-9 comprehensive physical performance testing system, the conductivity of the coating is about 7.8×10 -8 Ω m; the vacuum friction coefficient measured by the UMT-2 friction equipment of ...

Embodiment 3

[0065] Atmospheric plasma spraying powder is 10mass.%MoS 2 , 90mass.% Cu powder, the substrate for spraying is A3 steel, and the substrate is cleaned, degreased and sandblasted. The spraying parameters of the coating are set as: power 22kw, H 2 The flow rate is 4 SLPM, the Ar flow rate is 50 SLPM, the powder feeding rate is 50 g / min, and the spraying distance is 100 mm. The copper-molybdenum disulfide self-lubricating coating was obtained after 40 cycles of spraying at startup, and the product was removed for storage.

[0066] Using the PPMS-9 comprehensive physical performance testing system, the electrical conductivity of the coating is about 8.7×10 -8 Ω m; the vacuum friction coefficient measured by the UMT-2 friction equipment of the US CETR company is about 0.04, and the wear rate is about (5.4±0.33)×10 -4 mg / m, the friction and wear performance of the composite coating has been improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com