Mobile waste lamp tube safety recycling processing method and device thereof

A recycling and mobile technology, applied in the field of mobile waste lamp safety recycling and processing devices, can solve the problems of inability to collect fluorescent lamps in a centralized manner, unable to reach the waste lamp on-site for recycling, and bulky, etc., so as to solve the problem of difficult recycling and reduce Transportation cost, avoid breakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The invention is mainly used for crushing fluorescent tubes, collecting fluorescent powder and removing mercury gas. The equipment occupies a small area and has a simple and compact structure. It can be used in households, enterprises and institutions to process waste fluorescent lamps to prevent pollution and harm to the environment and human body after the waste fluorescent lamps are broken.

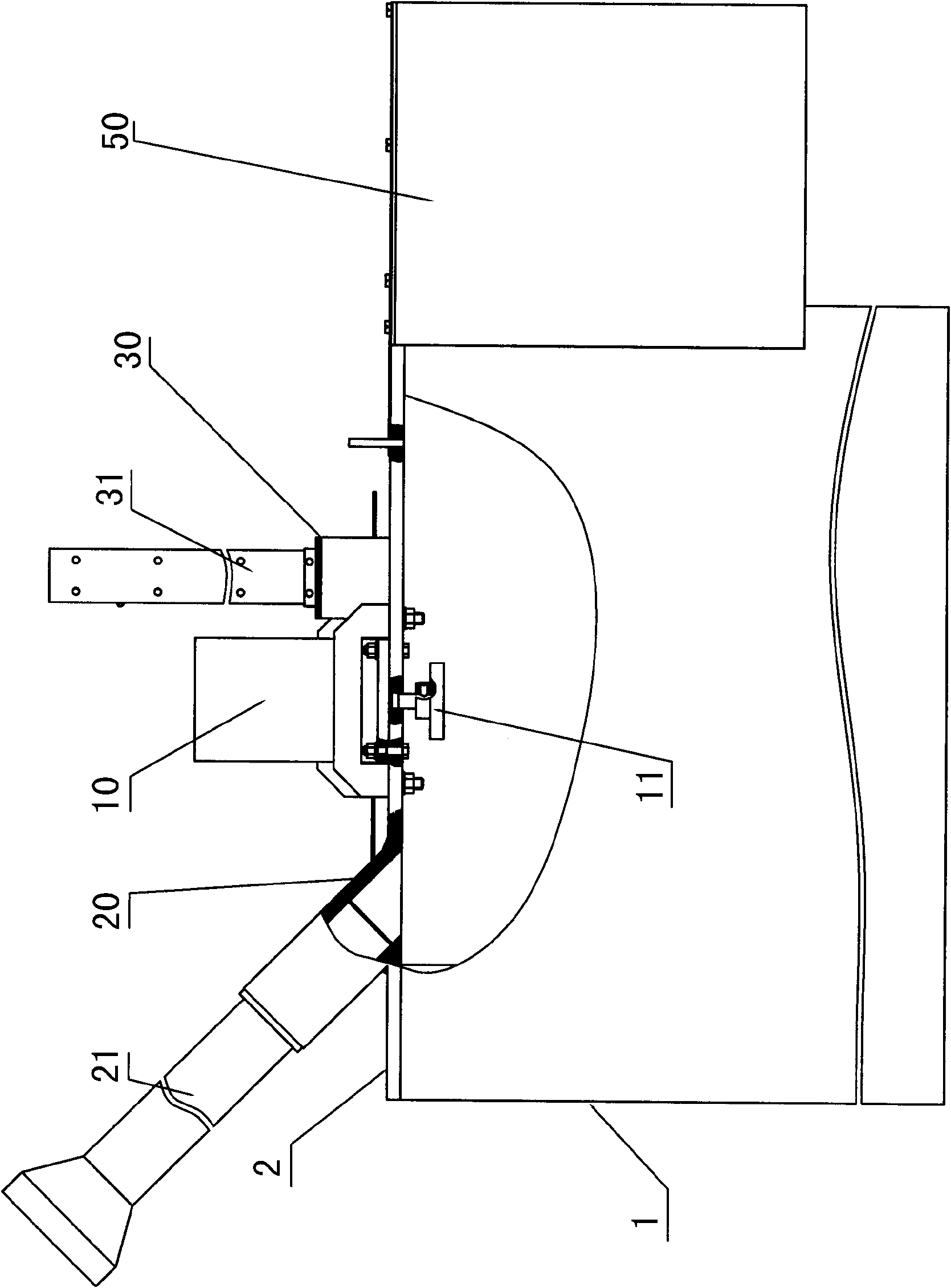

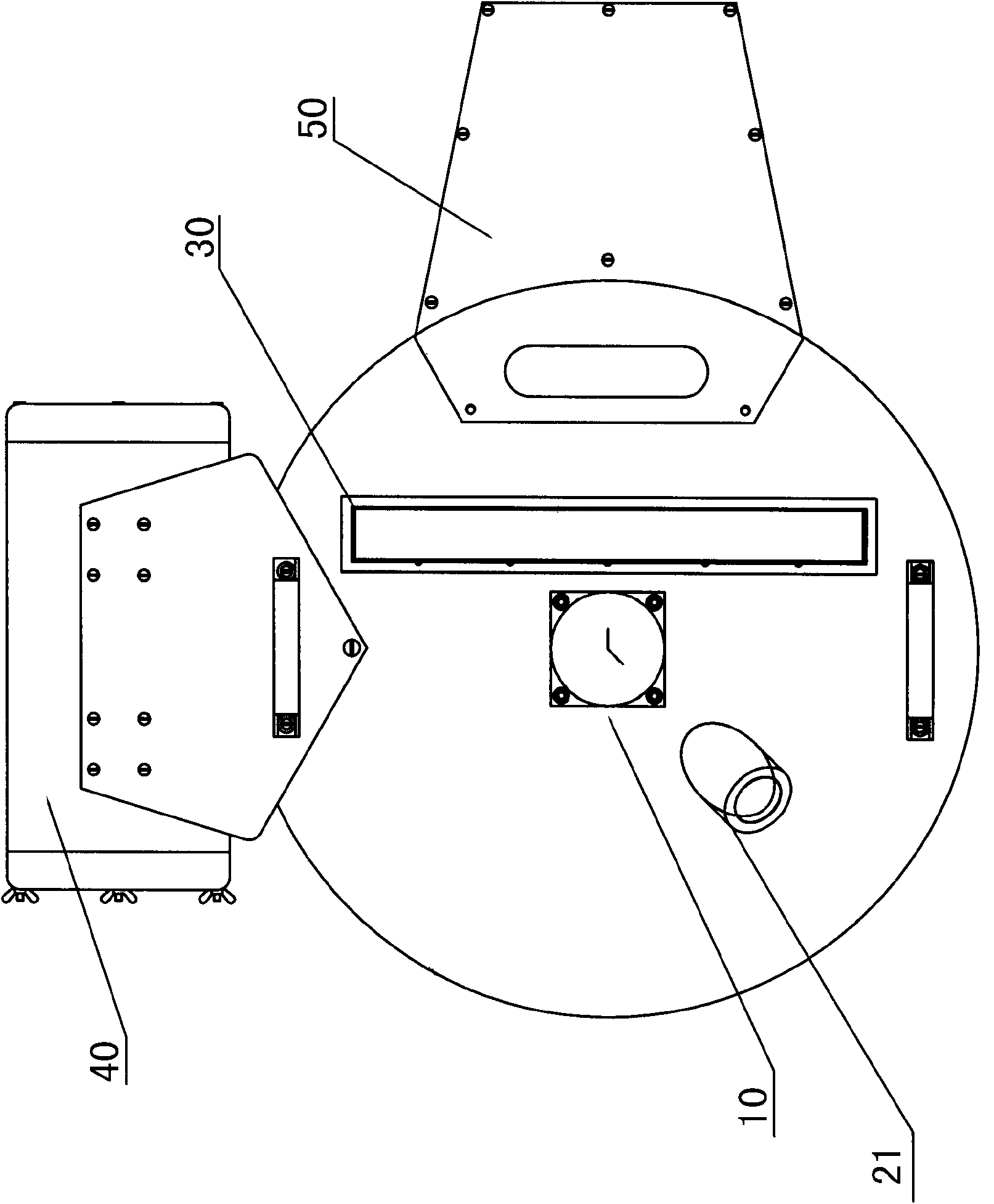

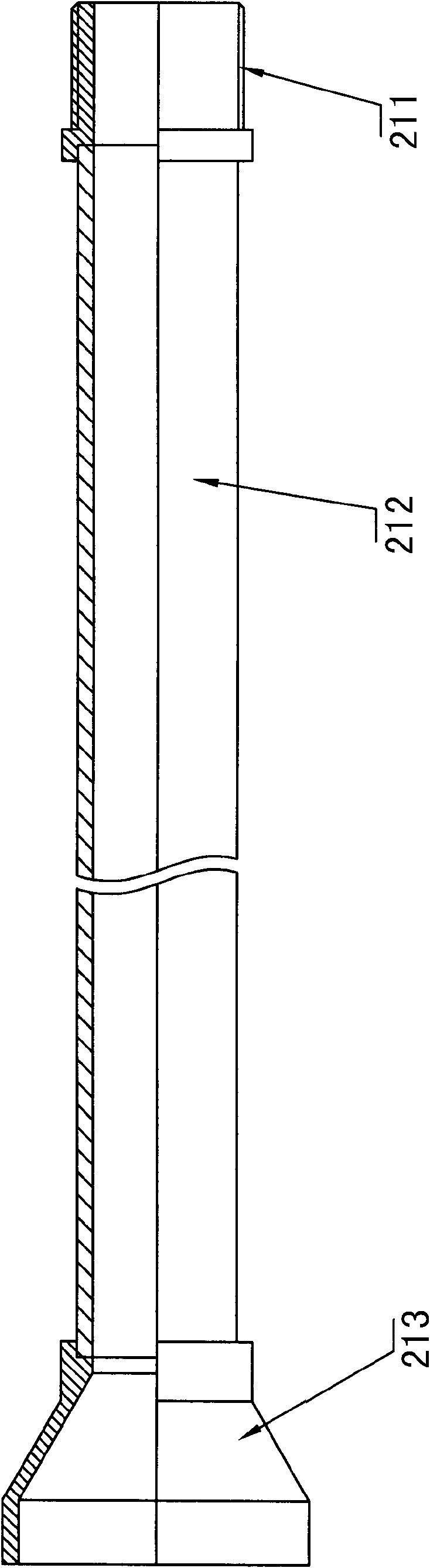

[0056] The mobile waste fluorescent lamp safe recovery processing equipment of the present invention is mainly composed of a feeding device, a lamp tube crushing device, an air filter and a mercury adsorption device. The straight lamp tube and the ring lamp tube enter from the corresponding feeding port respectively, and the high-speed rotating chain breaks the lamp tube, and the broken glass pieces are collected in the material barrel. The dust and mercury gas generated during the lamp tube breaking process are filtered through the filter bag filter to remove the coarse glass p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com