Derailment detector unit with extended sensitivity

A detector, technology for rail vehicles, in the field of derailment detector units with extended sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

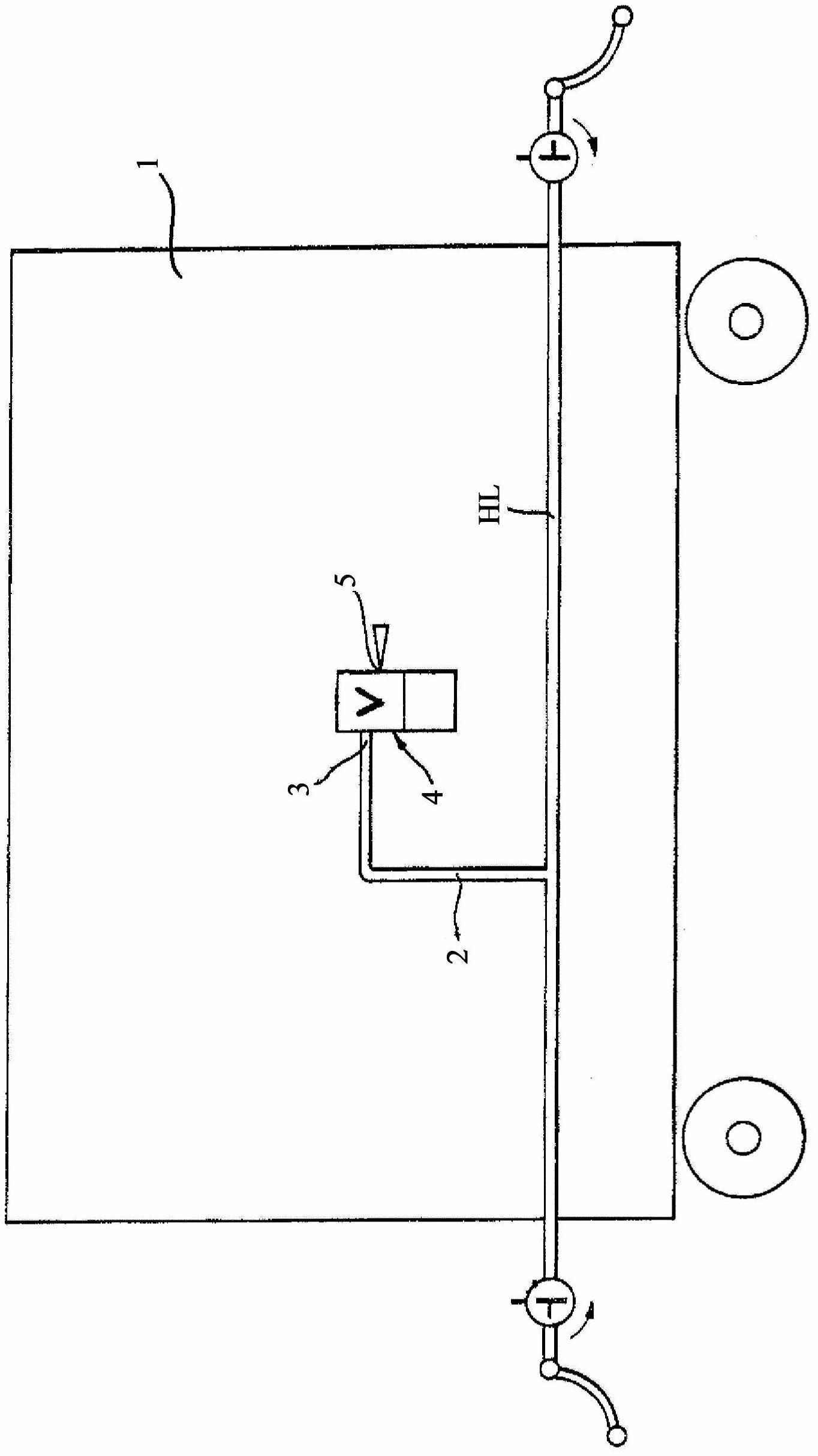

[0020] figure 1 A wagon 1 of a rail vehicle is shown. The main brake pipe HL of the compressed air brake system, not further shown, extends from one end of the wagon to its other end. A branch conduit 2 connects the main brake pipe HL of the compressed air brake system to the air inlet 3 of the derailment detector unit 4 . The derailment detector unit 4 detects defined vertical acceleration peaks on the rail vehicle in order to convert them into actuation shocks of the emergency brake valve assembly which are used to activate the service brake via the exhaust port 5 of the derailment detector unit 4 Pipe HL exhaust to drive the compressed air brake system.

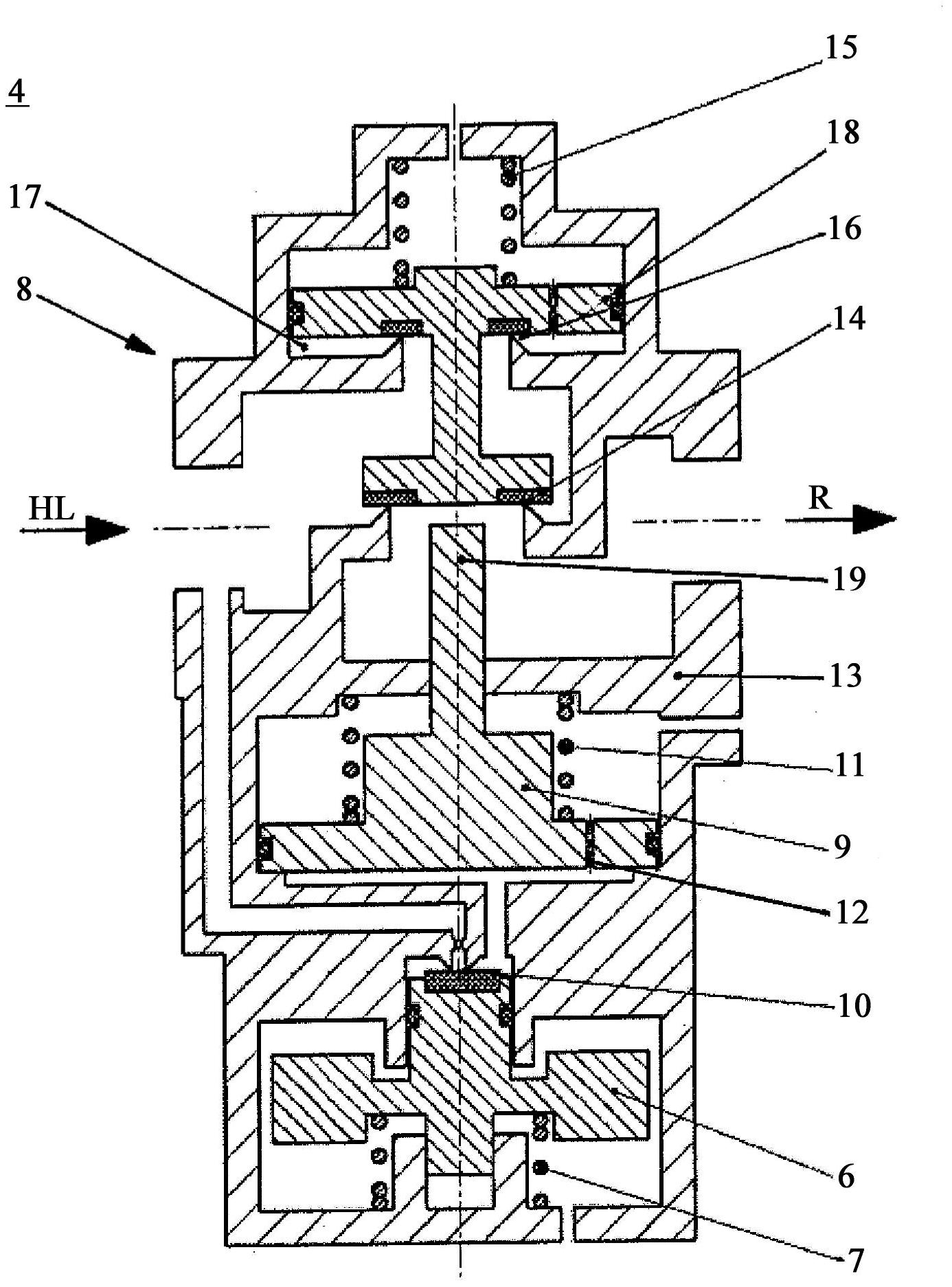

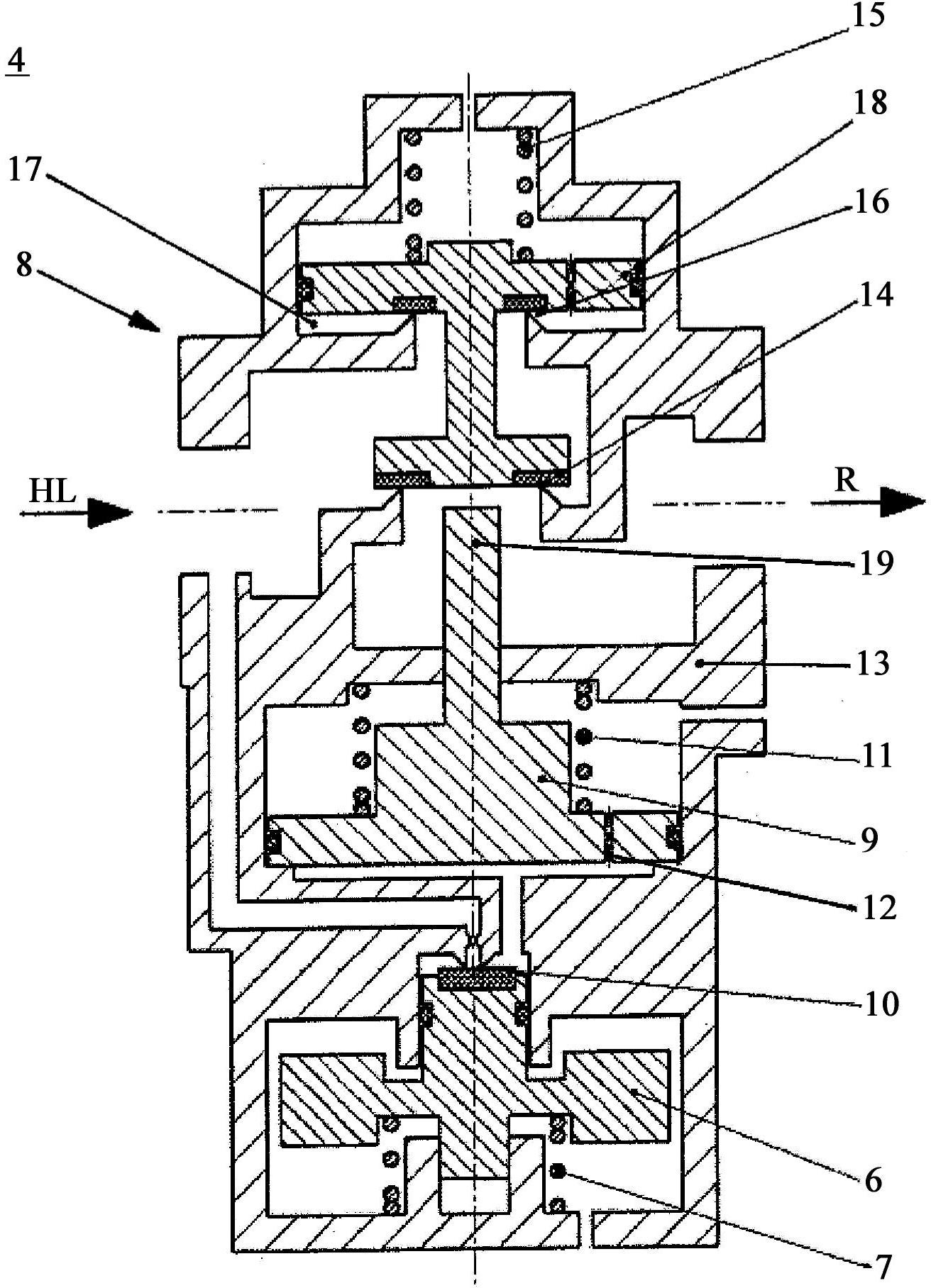

[0021] see figure 2 , The derailment detector unit 4 includes a vertically movable filling block 6 connected in series with a compression spring 7 . This mass-spring assembly converts the effective vertical acceleration peak into an actuation shock of the mechanically linked emergency brake valve assembly 8 for actuat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com