Novel venturi fertilizer absorber

A technology of Venturi and fertilizer suction device, applied in the field of new type of Venturi fertilizer suction device, can solve the problems of small negative pressure range of fertilizer suction port, unsatisfactory fertilizer suction effect, etc., so as to improve the fertilizer suction environment, improve the fertilizer suction effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

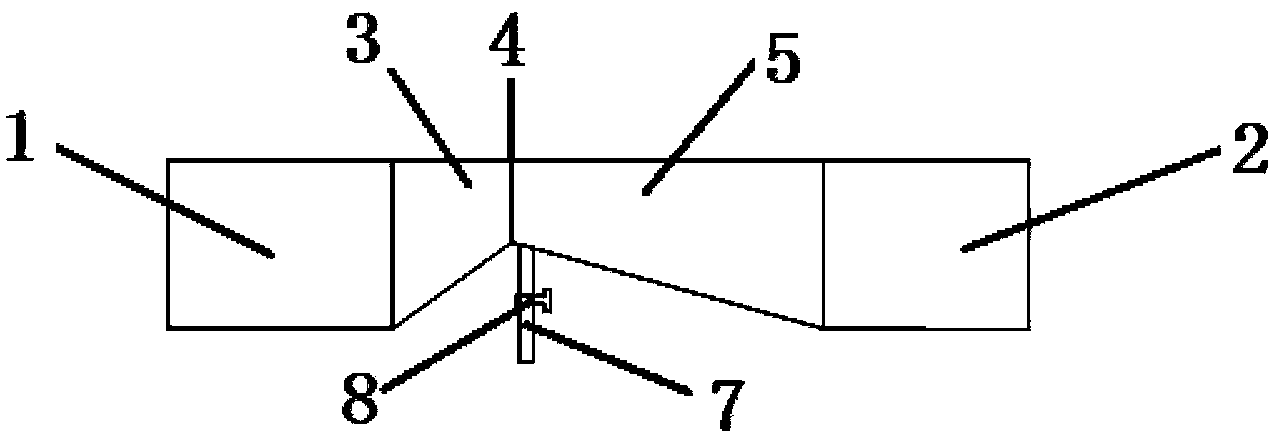

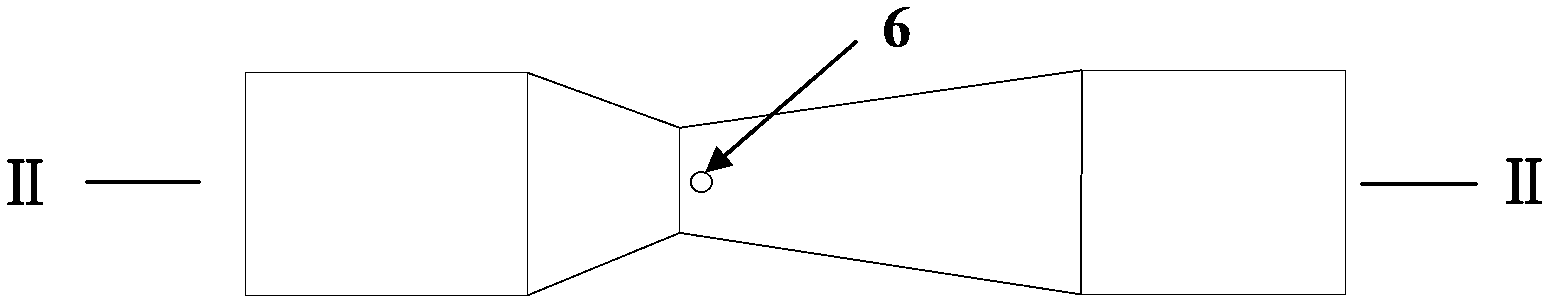

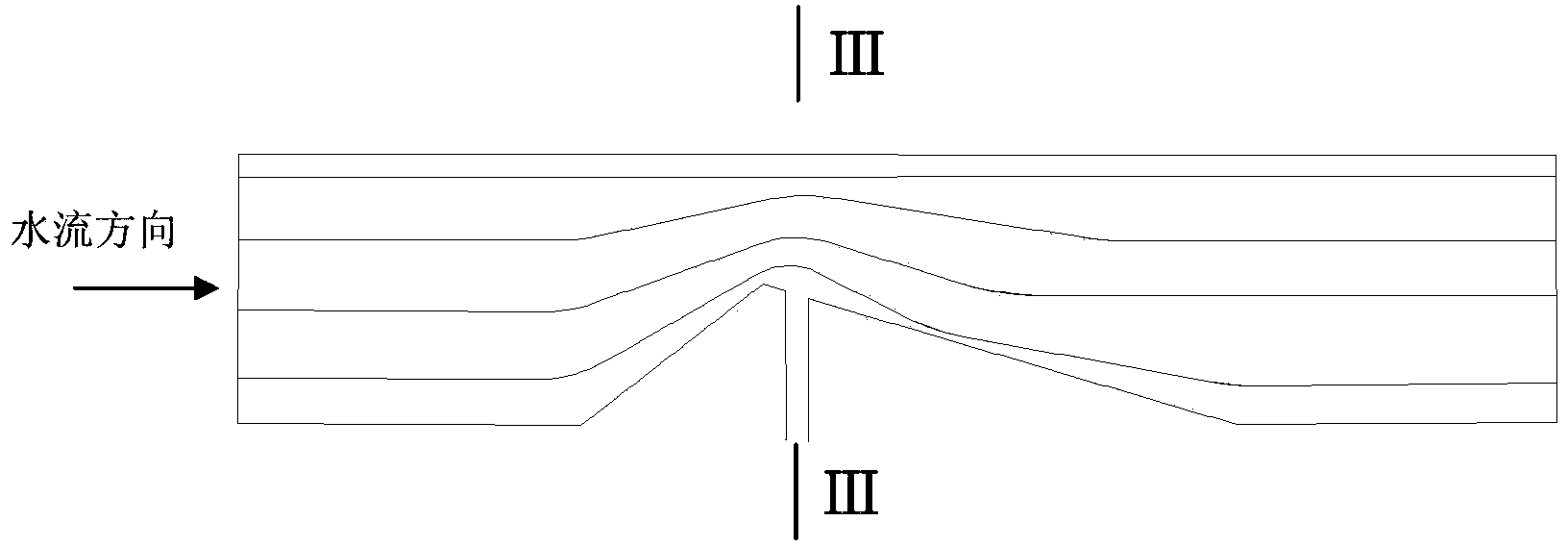

[0018] According to the principle of Venturi tube and relevant fluidics principles, the applicant, for a constant flow, the flow velocity of the fluid is inversely proportional to the area of the cross-flow section, and when the cross-section of the flow channel changes, the flow velocity of the fluid will change accordingly. When the cross-sectional area becomes smaller, the flow velocity increases; when the cross-sectional area becomes larger, the flow velocity decreases. For the Venturi tube, the flow velocity of the fluid theoretically reaches the maximum at the throat (the smallest cross-sectional area), but when the fluid is a pressure flow and the flow velocity is large, due to the joint action of pressure and flow velocity inertia (with the characteristics of jet flow), The maximum flow velocity of the fluid appears behind the throat of the Venturi tube, and there is a vacuum around the tube wall behind the throat (the throat of the Venturi tube is centrally symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com