Connection structure for cylinder and tube plate of tube-type falling-film evaporator

A falling film evaporator and connection structure technology, applied in vertical tube evaporators, evaporator accessories, etc., can solve problems such as stress corrosion, pipe hole deformation, lye leakage, etc., achieve stress corrosion reduction, simple structure, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

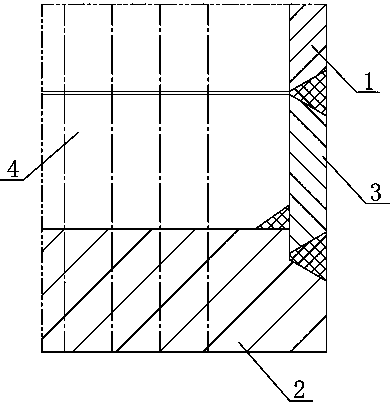

[0010] Such as figure 1 As shown, the connection structure between the cylinder and the tube sheet in the tubular falling film evaporator includes: the cylinder 1 and the tube sheet 2, and the cylinder nipple 3 is welded between the cylinder 1 and the tube sheet 2, so The cylinder short joint 3 is welded inside and outside the tube plate 1, and the height of the cylinder joint 3 is 300mm.

[0011] During processing, one end of the cylinder nipple 3 is first welded to the inside and outside of the tube sheet 2. Since the volume of the cylinder nipple 3 is small, it is possible to weld the welded cylinder nipple 3 together with the tube sheet 2. Stress relieving heat treatment is carried out. After the stress relieving heat treatment, the tube holes on the tube sheet 2 are processed, and finally the other end of the short joint 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com