A kind of polyethersulfone porous membrane used in membrane distillation process and preparation method thereof

A technology of polyethersulfone and porous membrane, which is applied in the field of porous membrane, can solve the problems that there are no public reports of membrane distillation membranes, increase the cost of PES membrane distillation membrane preparation, and the performance has not reached the mainstream level, etc., and achieve excellent membrane distillation performance , Membrane distillation performance is stable, and membrane distillation performance is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

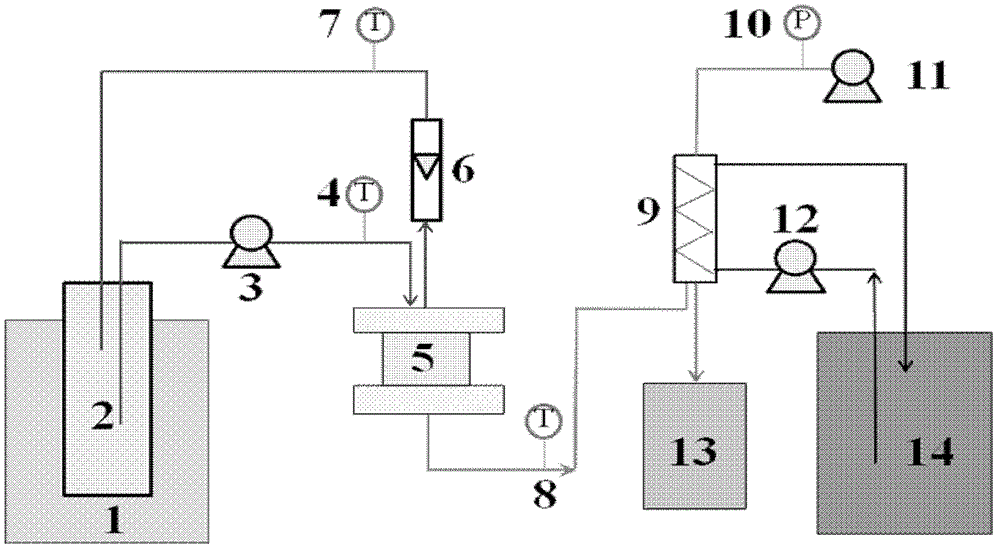

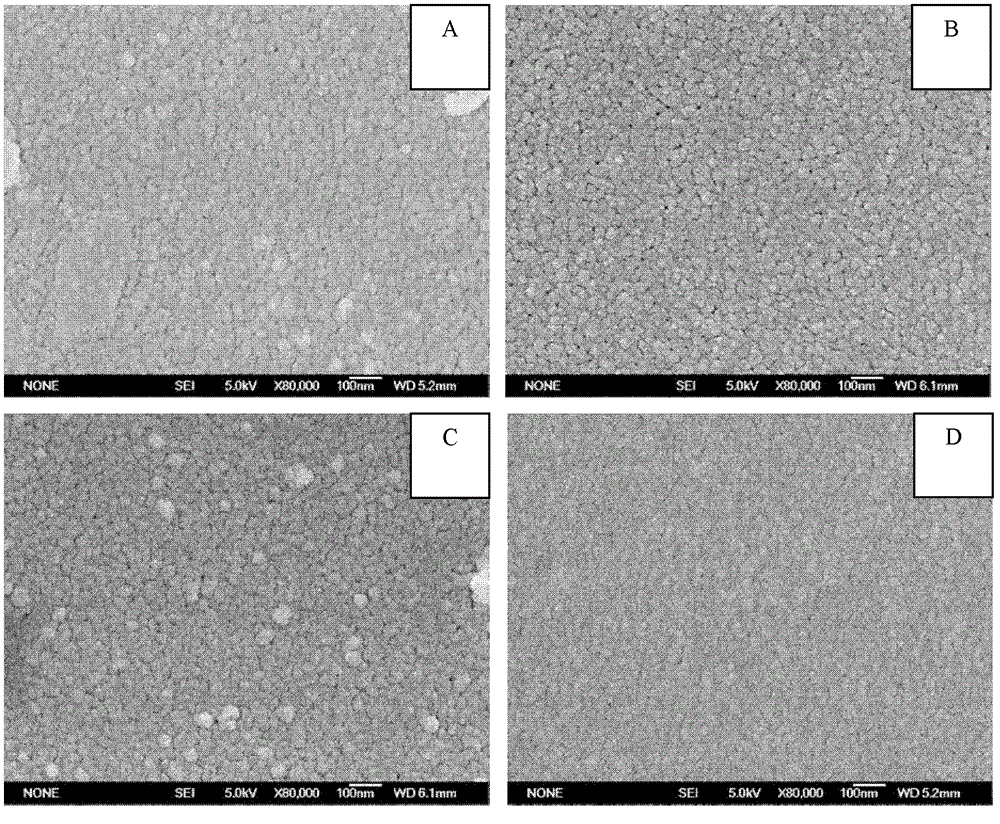

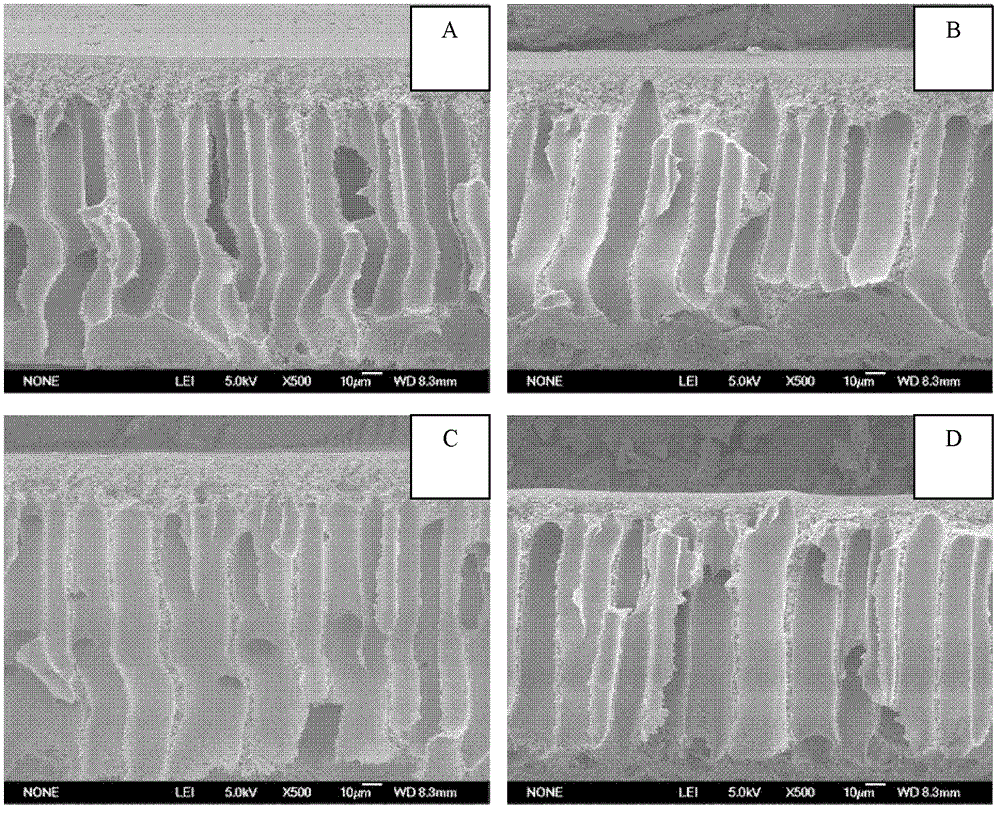

Embodiment 1

[0042] This example shows the structural characteristics and membrane distillation desalination performance of dry PES porous membranes obtained under different drying conditions. First, configure the casting film composition of PES17wt.%, PVP10wt.%, LiCl3wt.%, DMAC70wt.%, and scrape it flat on the polyester non-woven fabric under the conditions of room temperature, environmental relative humidity 35%, and film gap 250um. The sheet-type liquid nascent film forms a film after being immersed in deionized water at 20°C after staying in the air for 15 seconds. Among them, PES is E6020P, the K value of PVP is 30. After the film is formed, the drying treatment is carried out by using n-propanol replacement drying, isopropanol replacement drying, ethanol replacement drying and direct drying at room temperature, environmental relative humidity 35%, and atmospheric pressure. use figure 1 The shown vacuum membrane distillation evaluation system tests the membrane distillation desalinat...

Embodiment 2

[0054] This embodiment provides the film thickness of the dry PES porous membrane and its membrane distillation desalination performance when different solvents are selected. The same casting liquid composition, film forming conditions, raw material composition, evaluation system and evaluation conditions as in Example 1 were adopted. Among them, the membrane solvents were DMF, DMAC, NMP and DMSO, and the drying method was direct drying. The liquid temperature was 65°C, and the pressure on the downstream side of the membrane was 16,300 Pa. The results are shown in Table 3. It can be seen from Table 3 that the above four solvents can be used to prepare PES porous membranes suitable for membrane distillation desalination. Among them, the PES membrane obtained when DMAC is used as the solvent has the best membrane distillation desalination performance, and its casting solution viscosity is relatively moderate , The film thickness is relatively thinnest.

[0055] Table 3 PES casting...

Embodiment 3

[0058] This example shows the membrane distillation desalination performance of PES porous membranes obtained with different casting solutions. The same membrane production conditions, raw material liquid composition, evaluation system and evaluation conditions as in Example 1 were used. The drying method selected isopropanol replacement drying, the temperature of the feed liquid was 70 °C, the pressure on the downstream side of the membrane was 1300 Pa, and the feed liquid The circulation flow rate is 600ml / min, and the results are shown in Table 4. It can be seen from Table 4 that changing the composition of the casting solution can significantly adjust the membrane distillation desalination performance of the prepared PES porous membrane. When the composition of the casting liquid is selected as PES15wt.%, PVP10wt.%, H 2 When O3wt.% and DMAC72wt.%, the membrane distillation desalination performance of the PES porous membrane is relatively best. When the membrane is used to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com