Preparation method and application of homogeneous cation exchange membrane containing alkylbenzene sulfonate

A technology of cation exchange membrane and alkylbenzene sulfonate, which is applied in the field of exchange membrane to achieve the effect of excellent performance, mature membrane forming technology, environmental protection, and easy industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

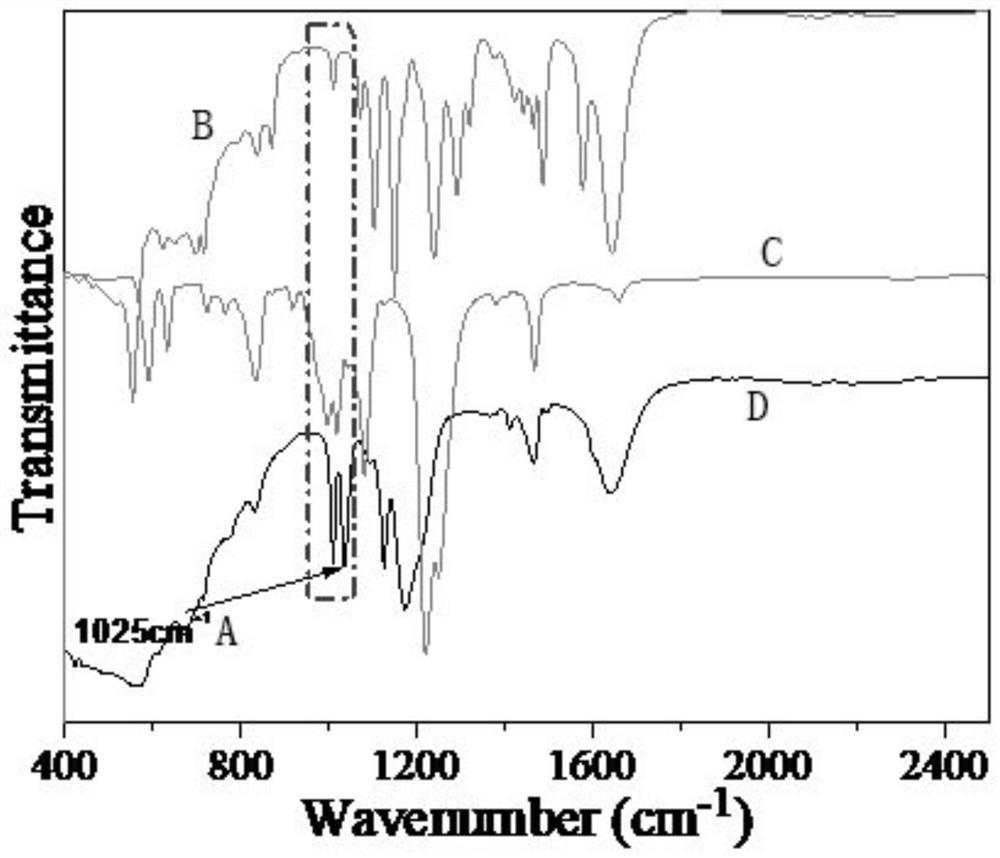

Method used

Image

Examples

Embodiment 1

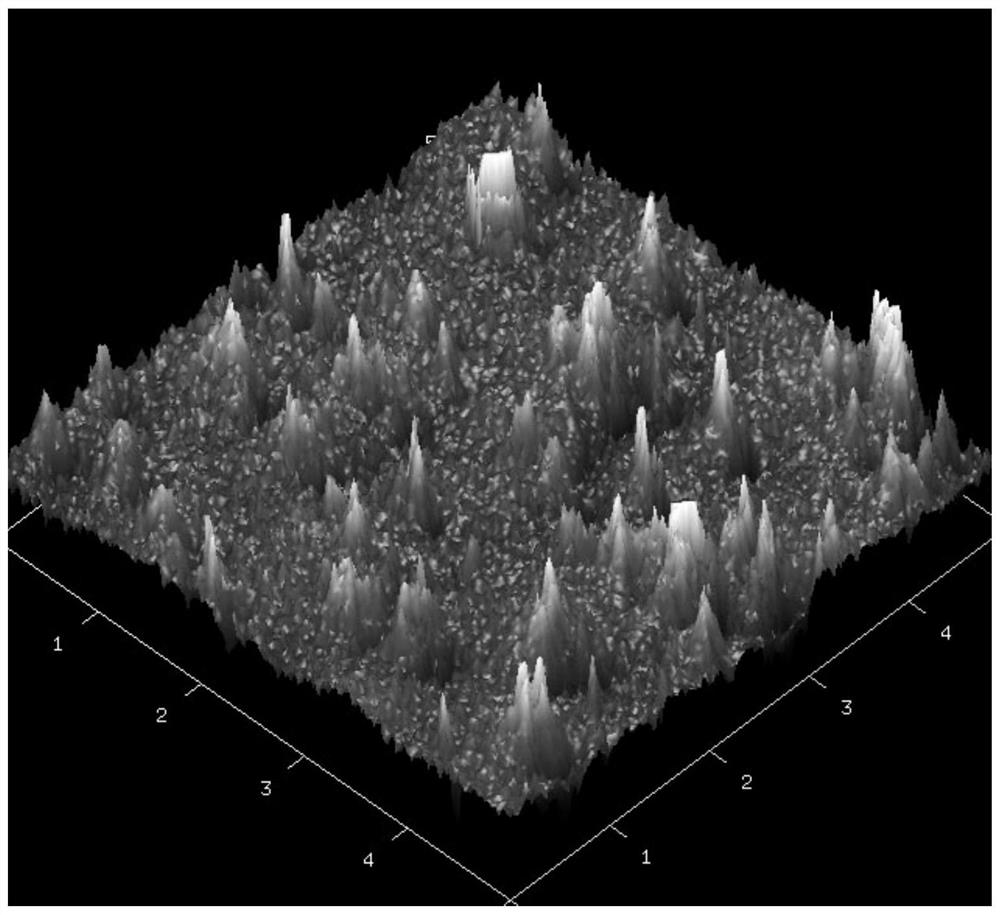

[0049]Mix 10g of polysulfone, 10g of PVP K60 and 70g of chloroform, and stir at 60°C for 10 hours. After it is completely dissolved, add 10g of sodium lignosulfonate and fully dissolve at 50°C to form a homogeneous solution. Ultrasonic defoaming at 80°C for 4 hours in the instrument, standing for defoaming for 24 hours, scraping the casting solution on a dry, smooth and clean glass plate, putting it in an oven, and gradually increasing the temperature: evaporate the solvent at 50°C for 5 hours, then heat up to 90°C to evaporate the solvent After 5 hours, the temperature was raised to 120°C to evaporate the solvent for 3 hours, and then it was taken out from the oven and cooled, then immersed in deionized water, and the ion-exchange membrane automatically fell off from the glass plate, which was the ion-exchange membrane of the present invention. After testing, the cationic membrane has a thickness of 183um, a water absorption rate of 32%, and an ion exchange capacity of 1.06mmo...

Embodiment 2

[0051] Mix 10g of polyethersulfone 2010, 8g of acetone and 100g of chloroform, and stir at 60°C for 10 hours. After it is completely dissolved, add 15g of sodium dodecylbenzenesulfonate, and fully dissolve at 60°C to form a homogeneous phase. After solution, ultrasonic degassing in an ultrasonic instrument at 60°C for 4 hours, standing still for degassing for 24 hours, scraping the casting solution on a dry, smooth and clean glass plate, putting it in an oven, and gradually increasing the temperature: evaporating the solvent at 50°C for 5 hours, then heating up Evaporate the solvent at 80°C for 4 hours, heat up to 130°C and evaporate the solvent for 4 hours, then take it out from the oven and cool it, then immerse it in deionized water, the ion-exchange membrane will automatically fall off from the glass plate, which is the ion-exchange membrane of the present invention. After testing, the cationic membrane has a thickness of 201um, a water absorption rate of 33%, and an ion ex...

Embodiment 3

[0053] Mix 15g of polyethersulfone 3010, 12g of PVP K120 and 90g of dimethylacetamide, stir at 50°C for 4 hours, after it is completely dissolved, add 12g of sodium octadecyl p-xylene sulfonate and fully dissolve at 70°C After the homogeneous solution is completely formed, ultrasonic defoaming in an ultrasonic instrument at 80°C for 5 hours, standing still for 24 hours, scraping the casting solution on a dry, smooth and clean glass plate, putting it in an oven, gradient heating: evaporation at 60°C Solvent for 5 hours, heat up to 90°C to evaporate the solvent for 5 hours, heat up to 120°C to evaporate the solvent for 3 hours, then take it out of the oven and cool it, then immerse it in deionized water, the ion-exchange membrane will automatically fall off from the glass plate, which is the ion-exchange membrane of the present invention . After testing, the thickness of the cationic membrane is 163um, the water absorption rate is 30%, and the ion exchange capacity is 0.96mmol / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com