Resin collecting and washing device for sodium heparin

A cleaning device and heparin sodium technology, applied in the direction of fixed filter elements, filtration and separation, and other chemical processes, can solve the problems of low work efficiency, increased production costs, time-consuming and labor-intensive, etc., to achieve high work efficiency and reduce labor costs The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

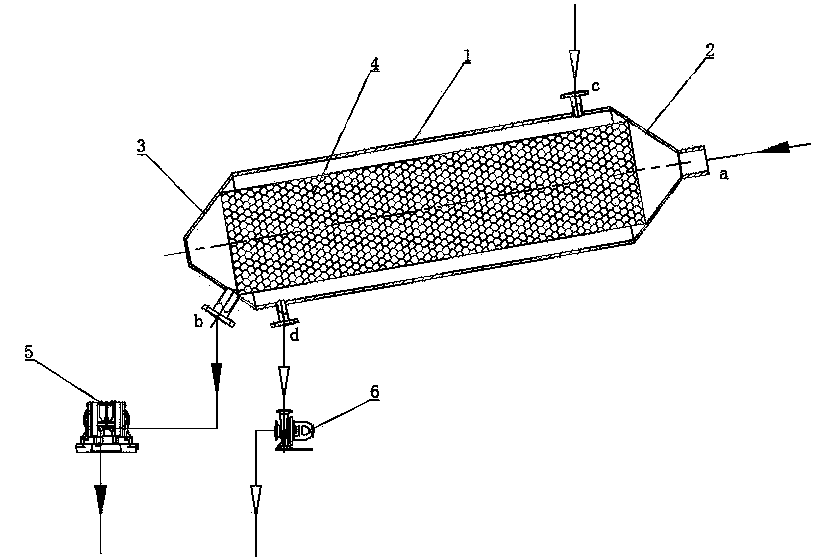

[0014] Such as figure 1 As shown, it includes the outer casing 1, the feed end head 2, the discharge end head 3, the inner filter cartridge 4, the material pump 5, the water pump 6, the feed port a, the discharge port b, the cleaning water inlet c, Rinsing water outlet d.

[0015] The two ends of the outer casing 1 are respectively provided with a feed end seal 2 and a discharge end seal 3, all of which are made of stainless steel. The head 2 of the feed end and the head 3 of the discharge end are of circular frustum-shaped structure, and the feed port a is set on the head 2 of the feed end, and the discharge port b is set on the head 3 of the discharge end. Specifically: The feed port a is located at the center of the head 2 at the feed end, and the discharge port b is located at the bottom of the head 3 at the discharge end.

[0016] The inner filter cylinder 4 is a screen cylinder with a mesh number of 40-100 mesh, which is coaxially installed in the outer shell 1, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com