Method for precleaning silicon wafer

A technology for pre-cleaning and silicon wafers, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as not being environmentally friendly, increasing sewage treatment costs, reducing mortar recycling rate, etc., to achieve improvement The effect of recycling rate and reducing the cost of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

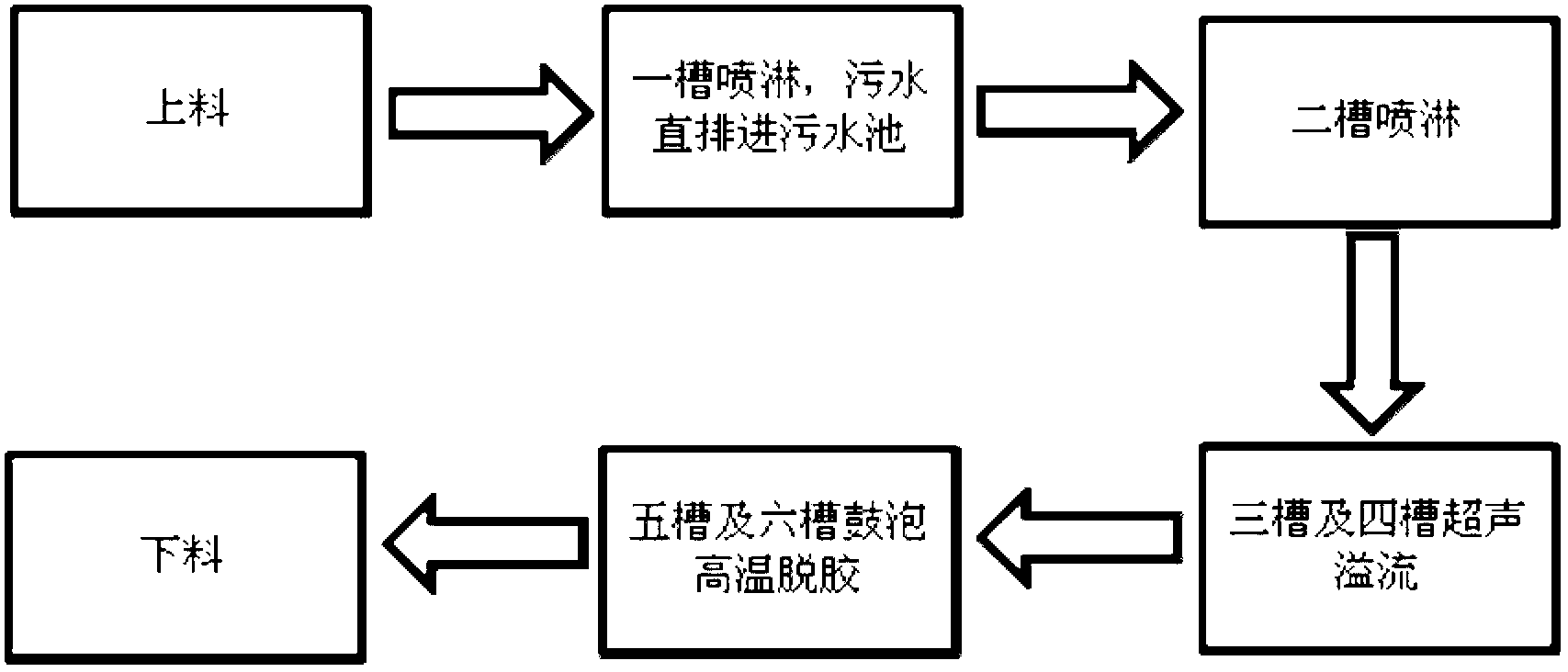

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

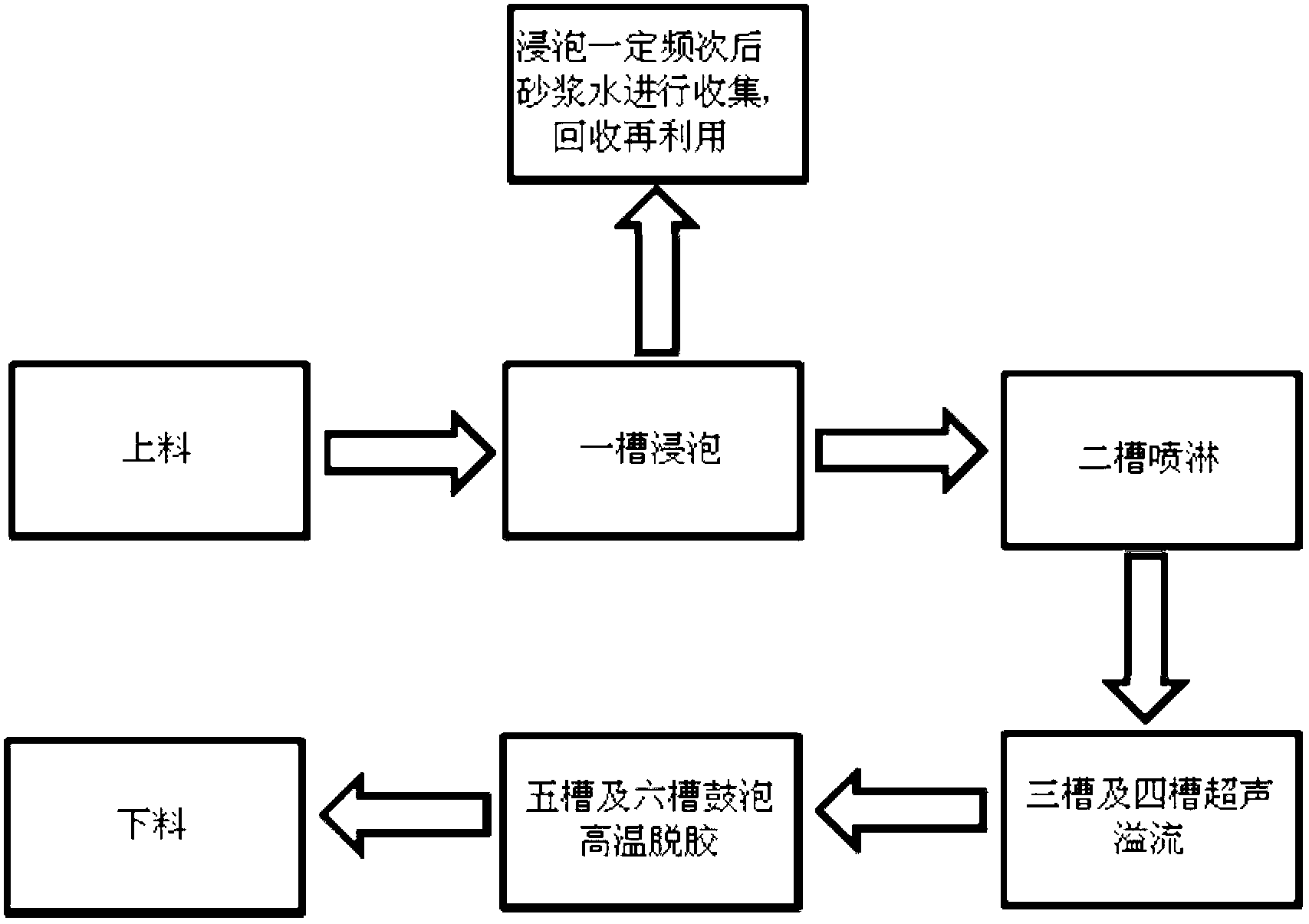

[0019] The idea of the silicon wafer pre-cleaning method in this embodiment is: when pre-cleaning the cut silicon wafers, the silicon wafers are soaked first, and then sprayed after soaking. Use soaking to remove most of the mortar on the silicon wafer, and use spray to remove a small amount of mortar remaining on the silicon wafer after soaking.

[0020] Most of the mortar on the silicon wafer after cutting is soaked and detached, which is convenient to collect the mortar water produced by soaking, so that the soaked mortar water can be recycled and reused in the mortar recycling enterprise, which improves the mortar recycling rate and reduces Sewage treatment costs, to achieve the purpose of environmental protection.

[0021] Usually, when pre-cleaning the cut silicon wafer, in addition to removing the mortar on the silicon wafer, processing steps such as ultrasonic overflow and degumming are also performed. Ultrasonic overflow is used to preliminarily remove some foreign...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap