Welding method for melting metal powder by laser scanning and device thereof

A technology of melting metal and laser scanning, applied in the field of foil parts welding, it can solve problems such as poor connection, deformation of foil parts, and penetration, and achieve the effect of overcoming deformation, high welding precision, and reducing non-welding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

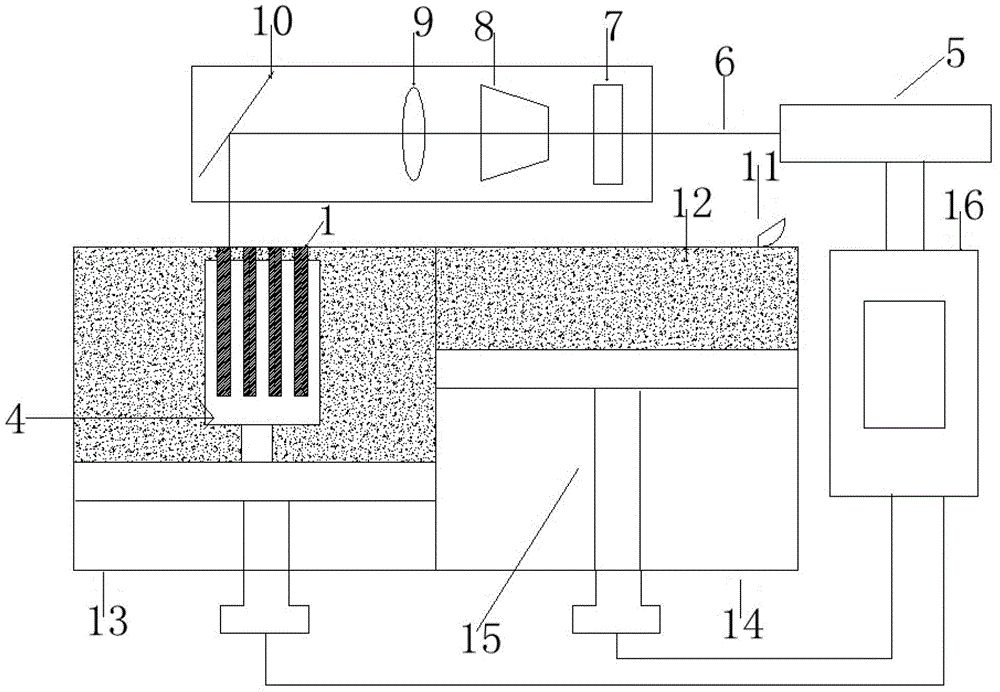

[0041] Such as image 3 , figure 2 As shown, the laser scanning molten metal powder welding device of the present invention includes a powder laying system and a laser welding system. The powder laying system includes a powder welding cylinder 13, a powder spreading scraper 11, a powder lifting cylinder 14, a lifting piston 15, and a computer 16. , the powder welding cylinder 13 is provided with a fixture 4, the lifting piston 15 is arranged at the bottom of the powder lifting cylinder 14; the laser welding system includes a fiber laser 5, a beam expander 7, a moving negative lens 8, a focusing mirror 9, scanning vibrating mirror 10; the powder welding cylinder 13, powder lifting cylinder 14, and fiber laser 5 are respectively connected to a computer 16.

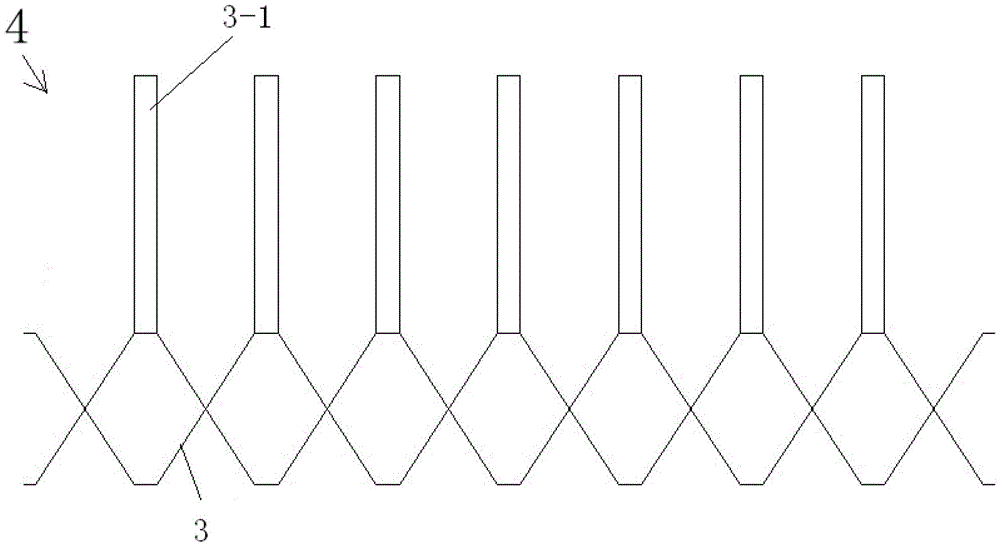

[0042] The clamp 4 is composed of a movable fence 3 and a splint 3 - 1 arranged on the movable fence 3 .

[0043] The scanning vibrating mirror 10 includes an X-axis mirror, a Y-axis mirror, an X-axis mirror servo motor, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com