Grinding machine for hardware tool

A technology for hardware tools and grinding machines, which is applied to metal processing machinery parts, manufacturing tools, grinding workpiece supports, etc. The effect of reducing the production cost of the enterprise and having a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

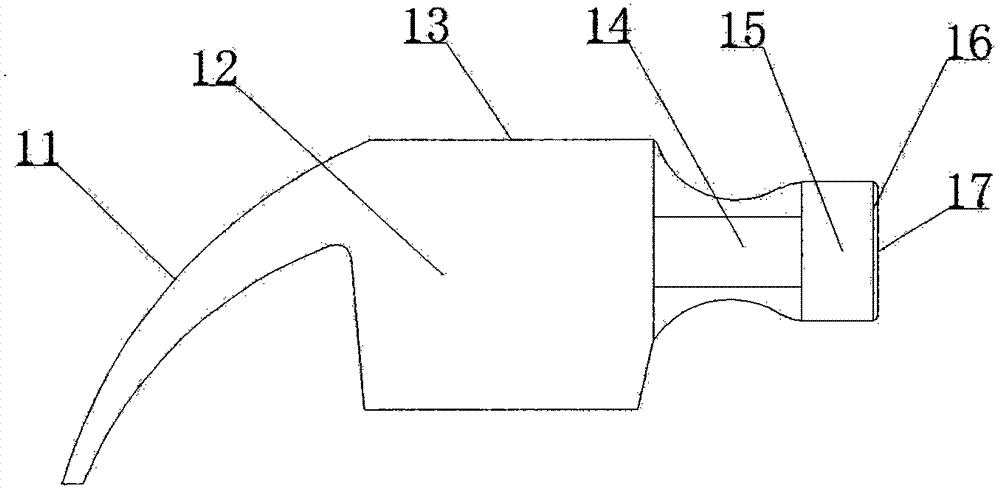

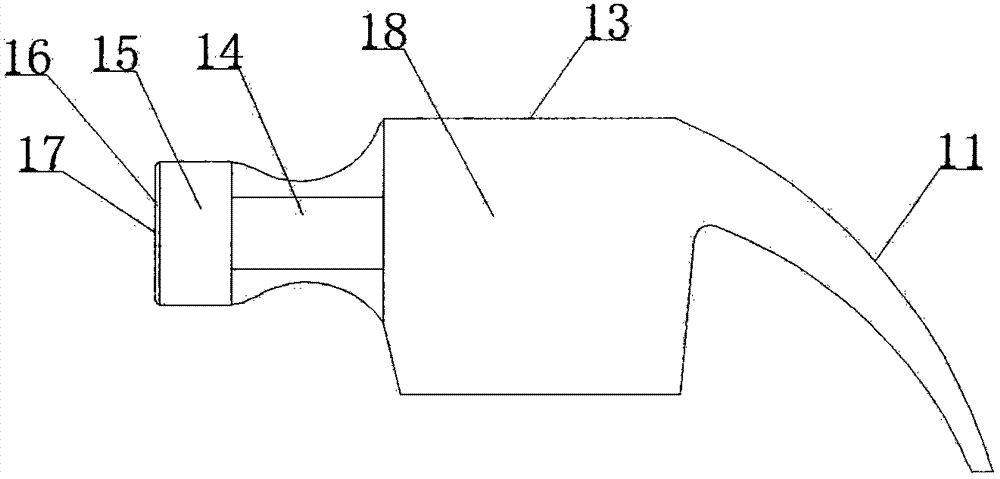

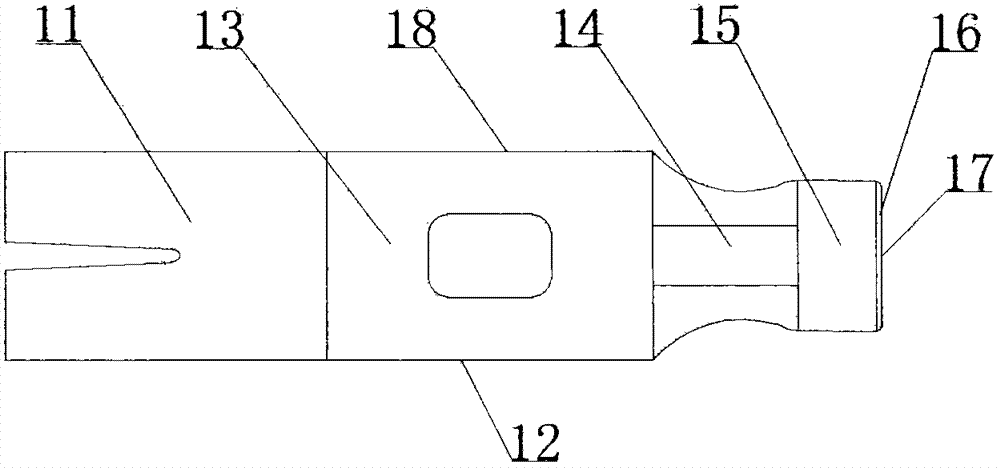

[0027] In this embodiment, the present invention is described in detail with the hammerhead as the working object of the grinding machine.

[0028] A hardware tool grinding machine, such as Figure 4 As shown, it includes: a box-type body 1; an electric control box 14, a power mechanism 3, a transmission mechanism 2 and a grinding system arranged in the body 1; an operation panel 11 arranged on the top of the body 1; On, the dust removal fan 7 for removing dust; the intelligent control device for controlling the power mechanism 3, the transmission mechanism 2, the grinding system and the dust removal fan 7 work.

[0029] Such as Figure 5 As shown, the power mechanism 3 is an adjustable speed motor 31, and the transmission mechanism 2 includes a speed reducer 22 and a transmission chainring 25, and the power output shaft 32 of the speed adjustable motor 31 is transmitted with the power input shaft 21 of the speed reducer 22. connect. A transmission gear 24 is fixedly mounte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap