Coking chemical product blower shutdown emergency device

A blower and coke oven technology, which is applied to the field of emergency devices for blower shutdown in coking production, can solve the problems of affecting the coke oven gas conversion reaction and the unqualified methane content of the reformed gas, and achieve the effects of ensuring safe production and increasing benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

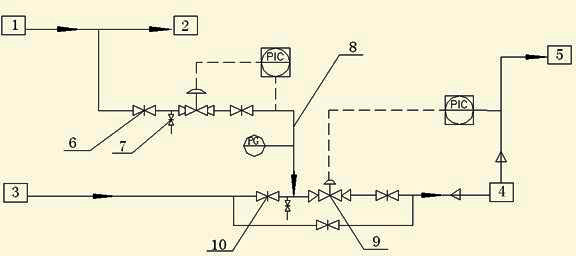

Image

Examples

Embodiment Construction

[0011] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment relates to a device for solving the problem of low fuel gas pressure in the co-production ammonia conversion preheating furnace, which is characterized in that a line with a cut-off valve 6 and pressure reducing The pipeline 8 of the valve 7 meets the front of the pressure control valve 9 and the rear of the upstream valve 10 of the pressure control valve group on the pipeline from the coking blower 3 to the fuel gas buffer tank 4 of the reforming preheating furnace 5. When the coking blower 3 suddenly shuts down due to an accident, the backup machine starts and runs normally for at least 10 minutes. Although the outlet pressure of the coking blower 3 drops from 8-11kpa to 0.36kpa in these 10 minutes, the height of the gas cabinet has no effect Large, the outlet pressure of coke oven gas compressor 1 is still normal. After the modification of the invention, before commission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com