Method for synthesizing 4,4'-diphenic acid

A technology of biphenyl dicarboxylic acid and p-bromobenzoic acid is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate and other directions, and can solve the problems of high requirements on reaction conditions, unsuitable for industrialized production, difficulty in separation and purification, and the like, Achieve the effects of low requirements for synthesis conditions, low production cost and simple purification method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

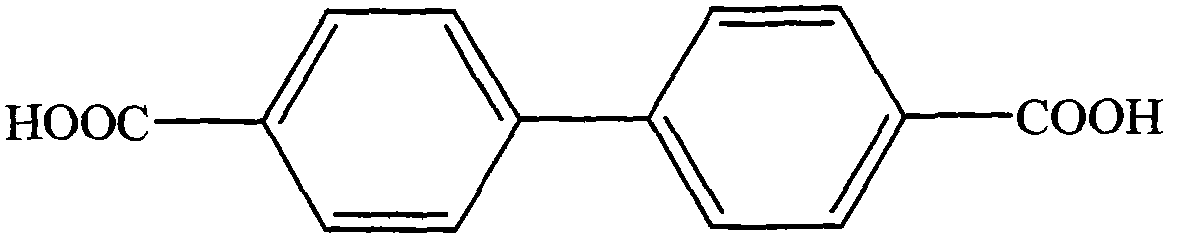

[0011] Such as figure 1 Shown, 4 of the present invention, 4 '-biphenyl dicarboxylic acid synthetic method is as follows:

[0012] 4,4'-biphenyldicarboxylic acid is obtained by reductive coupling using high boiling point polyethylene glycol 400 as a solvent and cuprous iodide as a catalyst in the presence of potassium hydroxide and piperazine .

[0013] The specific operation steps are: 2.5125 grams (12.5 millimoles) of p-bromobenzoic acid, 0.43 grams (5 millimoles) of piperazine, 0.2 grams (1 millimoles) of cuprous iodide, and 1.26 grams (22.5 millimoles) of potassium hydroxide Add 15 ml of polyethylene glycol 400, keep the temperature at 80°C and react for 72 hours, the color of the solution is brown, stop the reaction, add 1 mol / L of hydrochloric acid solution drop by drop until a large amount of white precipitates are formed, the pH of the solution is 3, then extract the product with chloroform, and then repeatedly wash the chloroform layer with saturated brine and water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com