Inorganic soil curing agent and preparation method thereof

A soil curing agent and curing agent technology, applied in chemical instruments and methods, soil conditioning materials, organic fertilizers, etc., can solve problems such as unsatisfactory curing effect, impact on promotion and application, compatibility limitations, etc., to save resources and transportation. Cost, good curing effect, strength increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Soil stabilizer of the present invention, its component and weight ratio are:

[0024] Cement clinker: 39%, secondary or above fly ash: 35%, slag: 10%, quicklime: 12%, dihydrate gypsum: 2%, alkaline activator 2%, the sum of the above raw materials is 100% .

Embodiment 2

[0025] Embodiment 2: soil solidifying agent of the present invention, its component and weight ratio are:

[0026] Cement clinker: 34%, secondary or above fly ash: 35%, slag: 15%, quicklime: 12%, dihydrate gypsum: 2%, alkaline activator 2%, the sum of the above raw materials is 100% .

Embodiment 3

[0027] Embodiment 3: soil solidifying agent of the present invention, its component and weight ratio are:

[0028] Cement clinker: 40%, secondary or above secondary fly ash: 30%, slag: 15%, quicklime: 12%, phosphogypsum: 3%, the sum of the above raw materials is 100%.

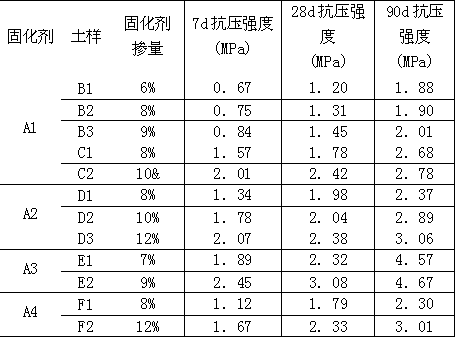

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com