Three-shafting composite spinning method of constant-tension double-filament adjoining and twisting triangular zone and application thereof

A composite spinning and equal tension technology, which is applied to spinning machines, yarns, textiles and papermaking, etc., can solve the problems of ineffective use of short fibers, etc., and achieve the effect of practical mechanism, convenient installation and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

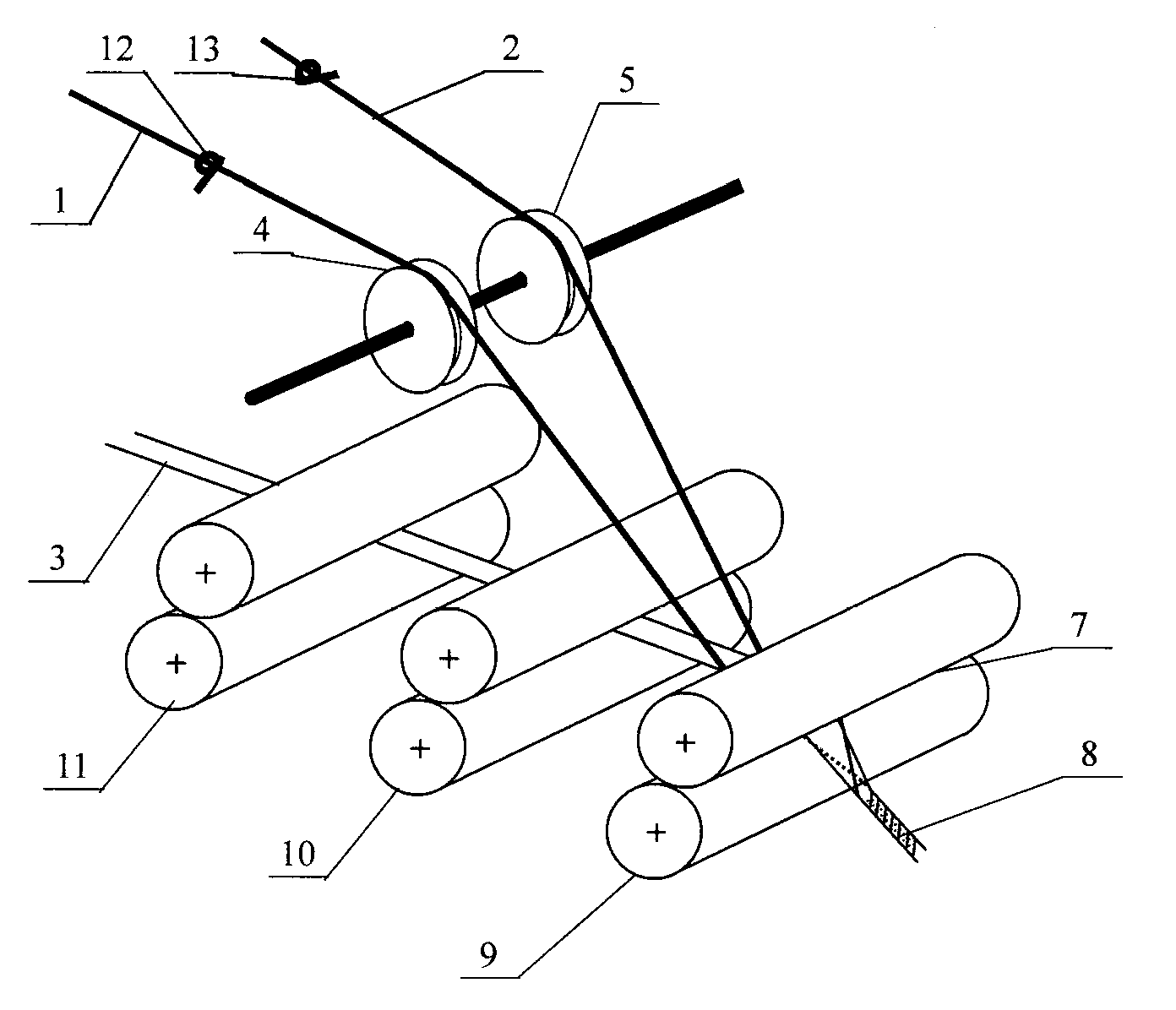

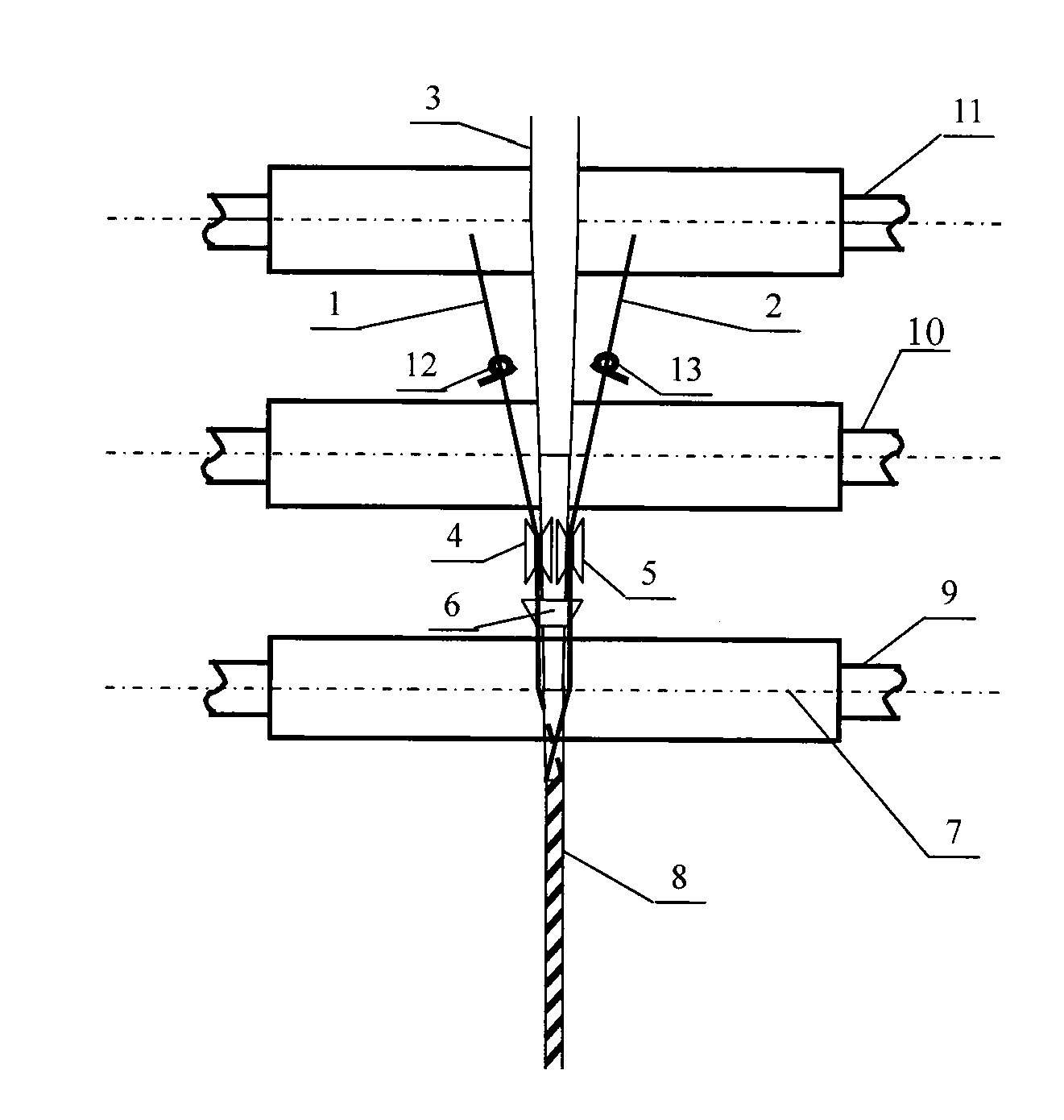

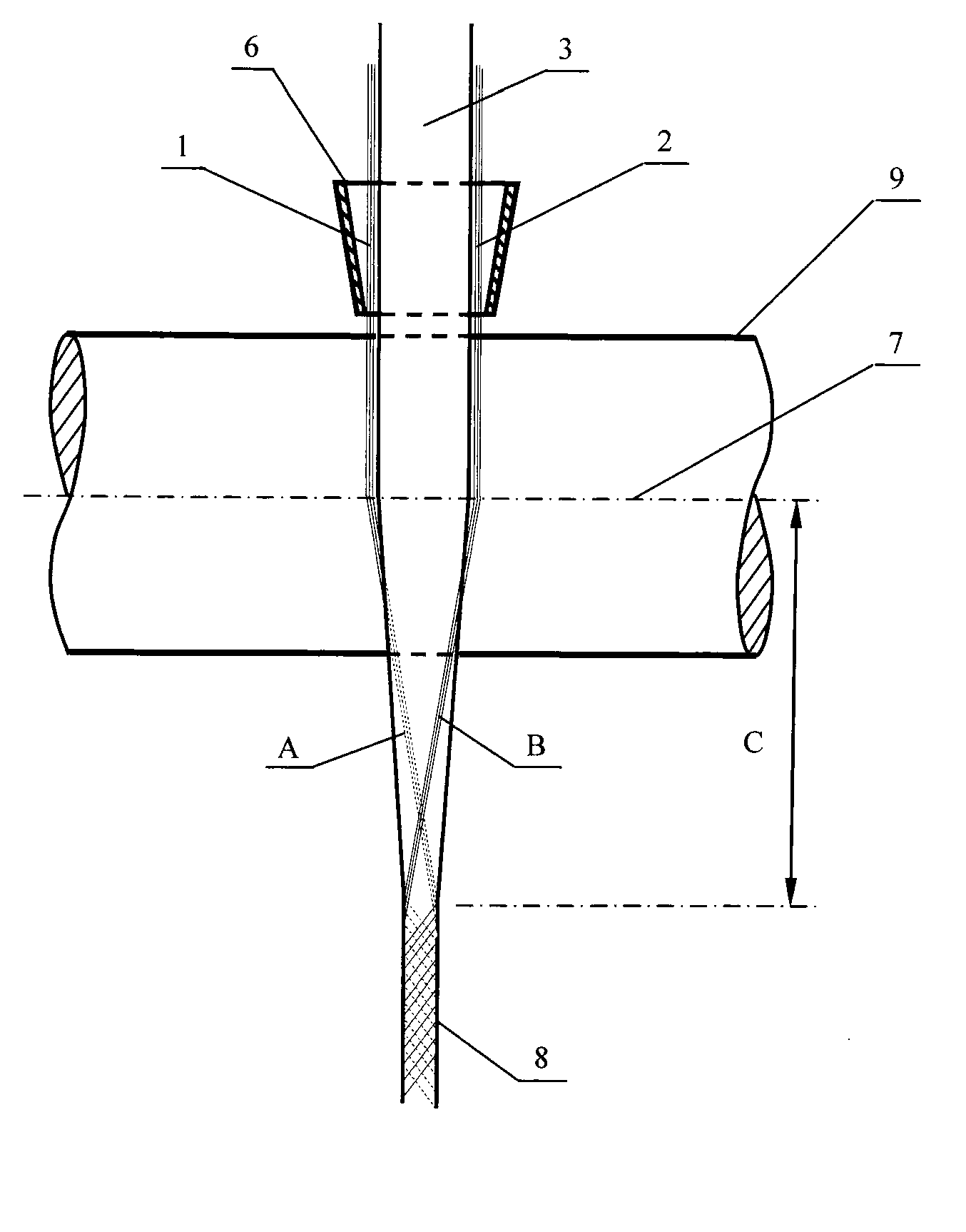

[0031] Embodiment 1: Spinning recycled cotton / viscose filament composite yarn

[0032] Select one tube of recycled cotton roving and two tubes of viscose filaments for three-axis high-count yarn compound spinning, first unwind the next recycled cotton roving from the roving tube and pass through the drafting of back roller 11 and middle roller 10 Form the recycled cotton short fiber strands 3, and then pass through the bundler 6; at the same time, the viscose filament 1 and the viscose filament 2 are unwound from the filament tube, and are wound on the left tension through the left yarn guide hook 12 respectively. The wheel 4 and the right yarn guide hook 13 wind around the right tension wheel 5, and then pass through the cluster 6 symmetrically; then the left viscose filament, the right viscose filament and the recycled cotton staple fiber triaxial system are fed synchronously In the jaws of the front roller 9, viscose filaments are formed to be clamped and protected by dammi...

Embodiment 2

[0033] Embodiment 2: Spinning soil seed wool / nylon filament composite yarn

[0034] Select one tube of soil-type wool roving and two tubes of nylon filament to carry out three-axis high-count yarn composite spinning. Soil-type hair short fiber strands 3, then pass through the bundler 6; at the same time, the left nylon filament and the right nylon filament are unwound from the filament tube, and are wound around the left tension wheel 4 and the left tension wheel 4 through the left yarn guide hook 12 respectively. The right yarn guide hook 13 winds around the right tension wheel 5, and then passes through the cluster 6 symmetrically; then the triaxial system of the left nylon filament, the right nylon filament and the short fiber of soil species is synchronously fed into the clamp of the front roller 9 In the mouth, it forms the damming and clamping protection of nylon filaments on both sides of the soil-type hair strips; when the three bundles of fiber strips are output from ...

Embodiment 3

[0035] Embodiment 3: Spinning recycled cashmere / silk composite yarn

[0036] Select one tube of recycled cashmere roving and two tubes of silk to carry out three-axis ultra-fine yarn compound spinning, firstly unwind from the roving tube, and then use cashmere roving to pass through the drafting of rear roller 11 and middle roller 10 to form a loop. Use short cashmere fiber strands, and then pass through the bundler 6; at the same time, the left silk and the right silk are unwound from the filament tube, and are wound around the left tension wheel 4 through the left yarn guide hook 12 and passed through the right yarn guide hook 13 respectively. Wrap around the right tension wheel 5, then pass through the bundler 6 symmetrically; then feed the triaxial system of left silk, right silk and recycled cashmere staple fiber synchronously into the jaws of the front roller 9 to form silk in the recycled cashmere staple Damming and clamping protection on both sides; when the three bund...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com