Patents

Literature

35results about How to "Stable yarn structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

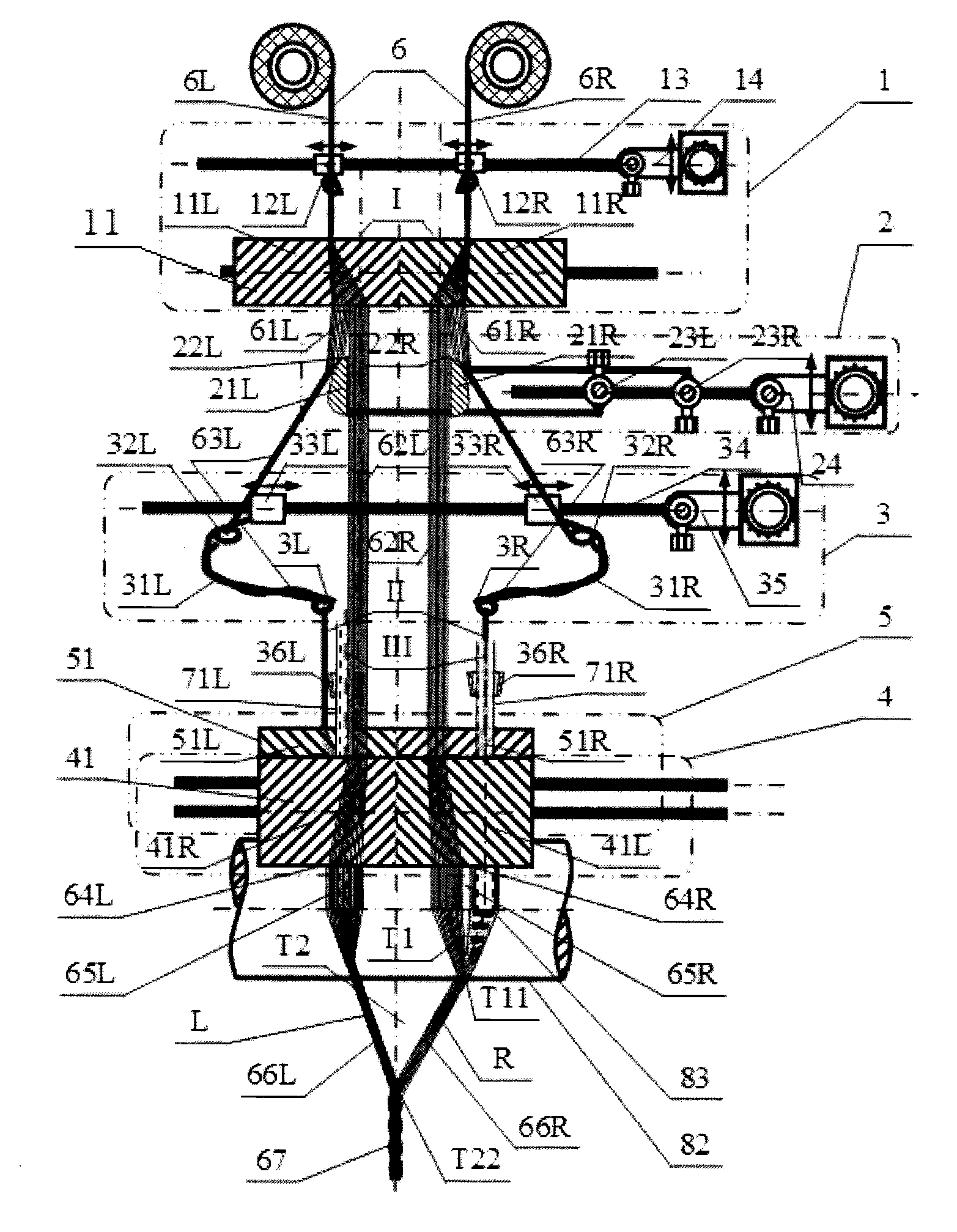

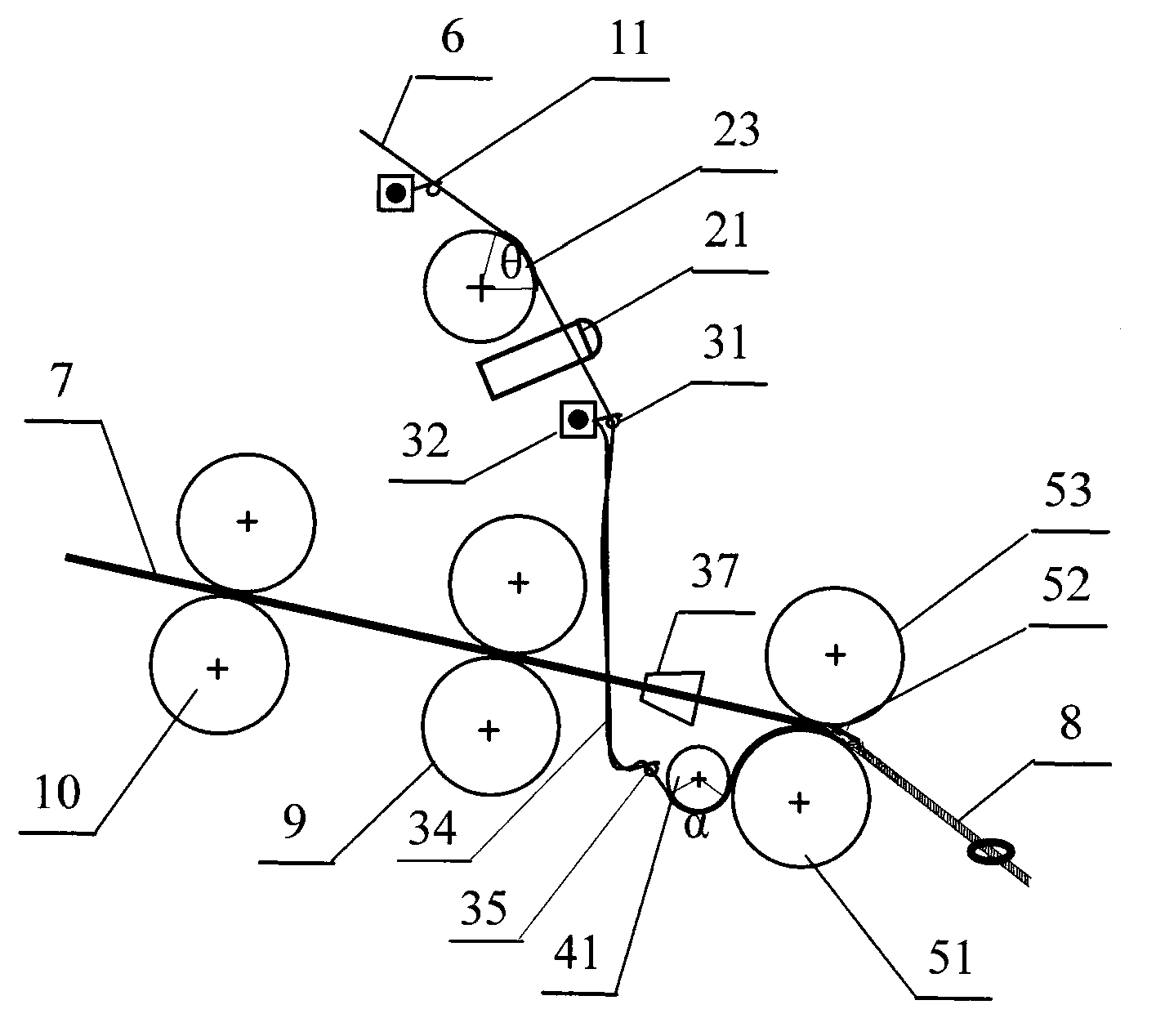

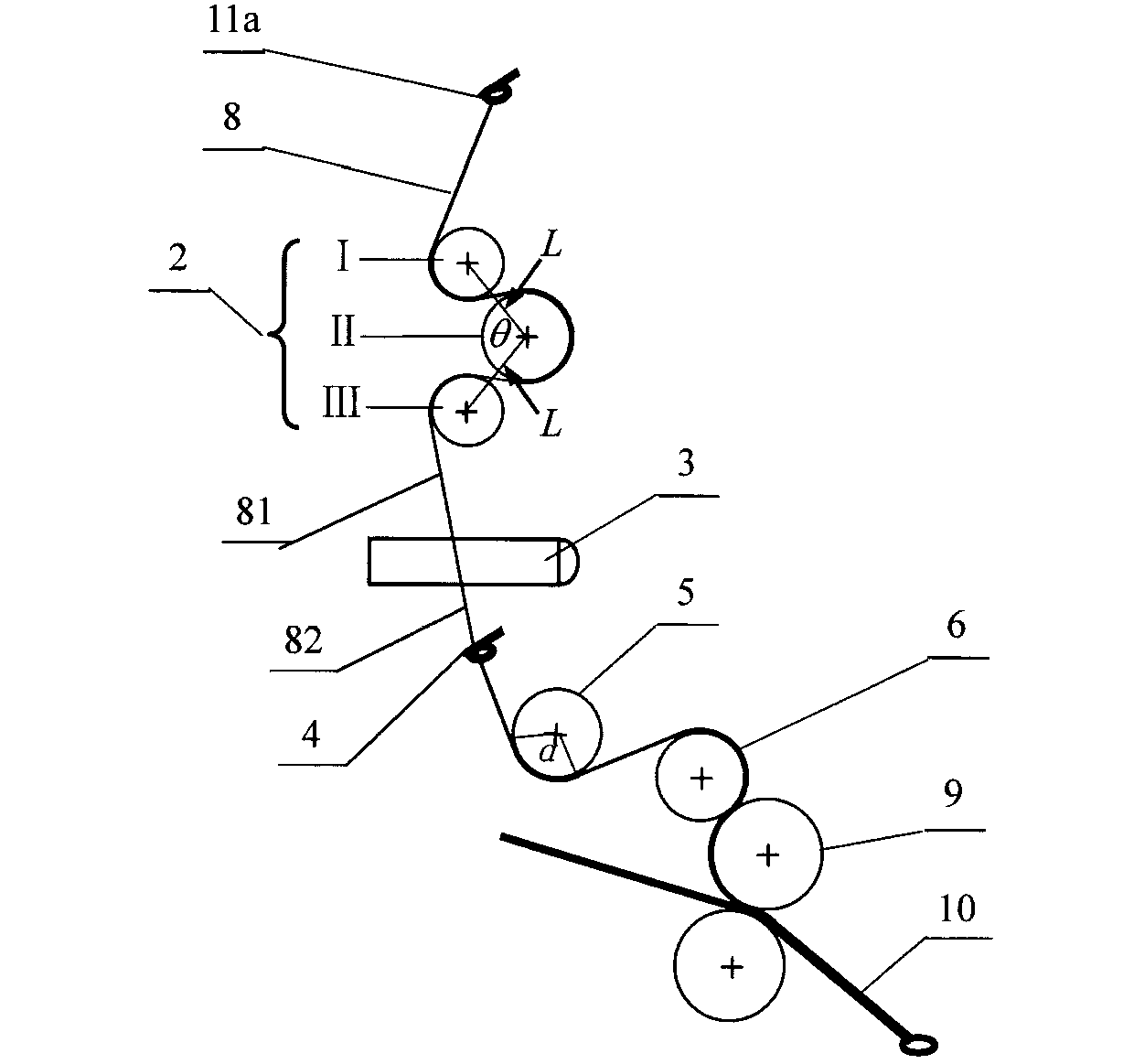

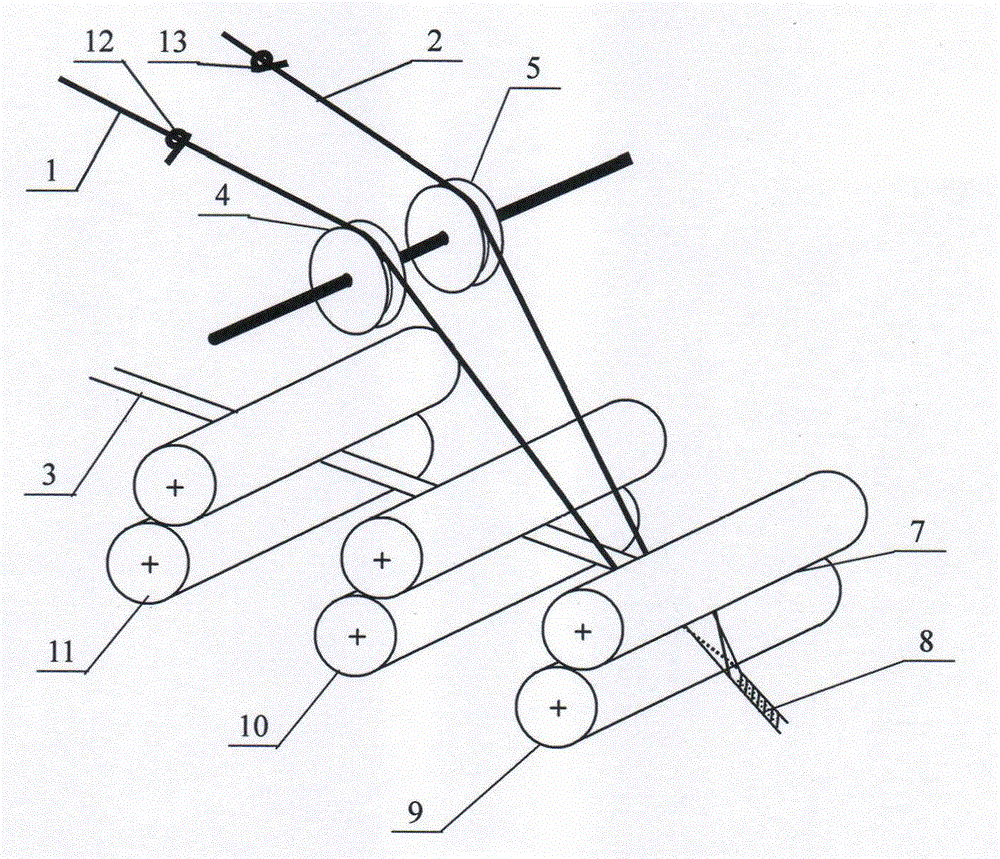

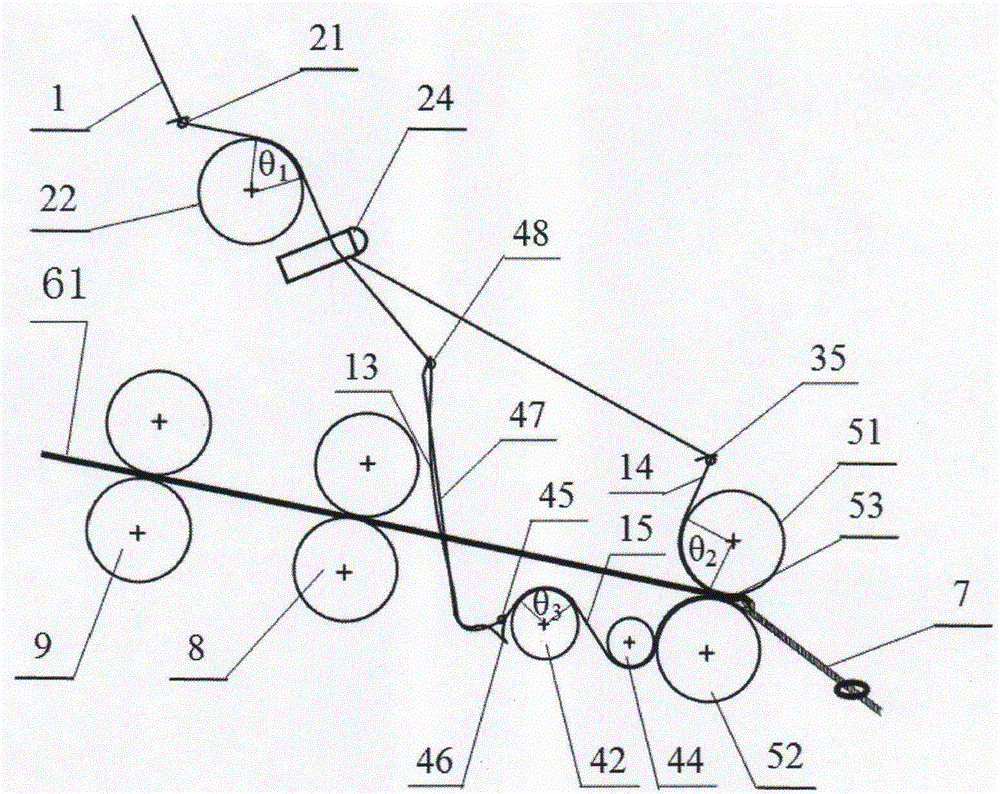

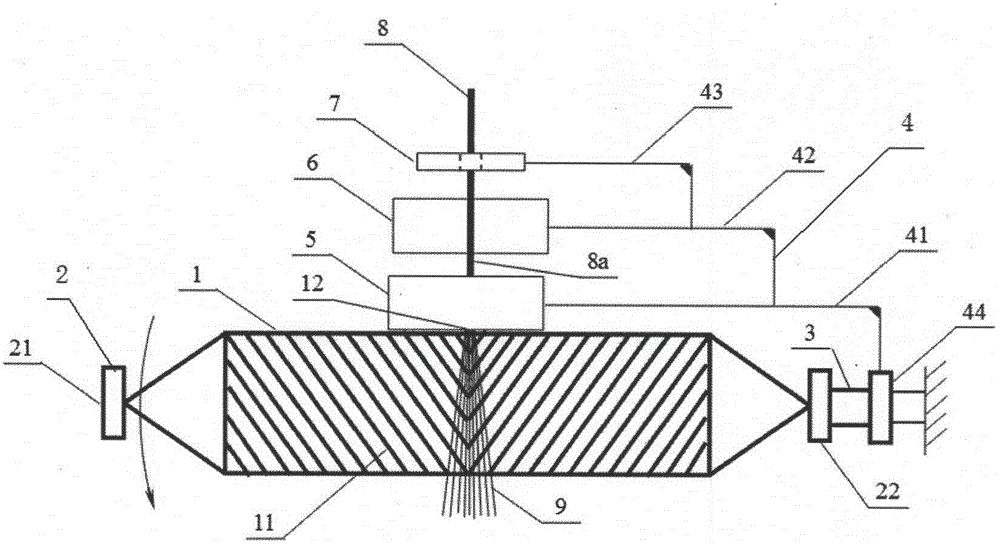

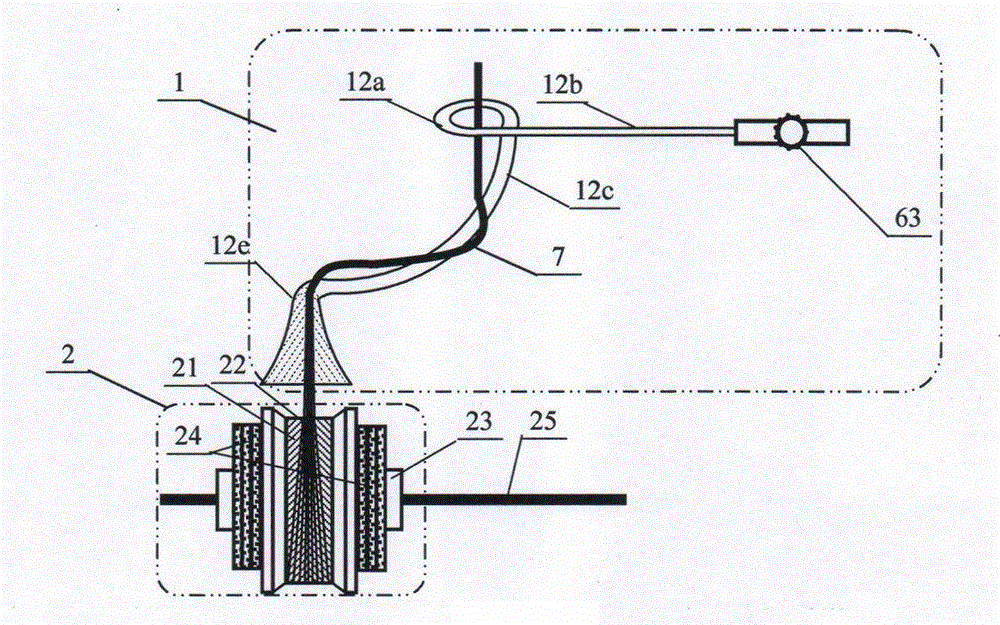

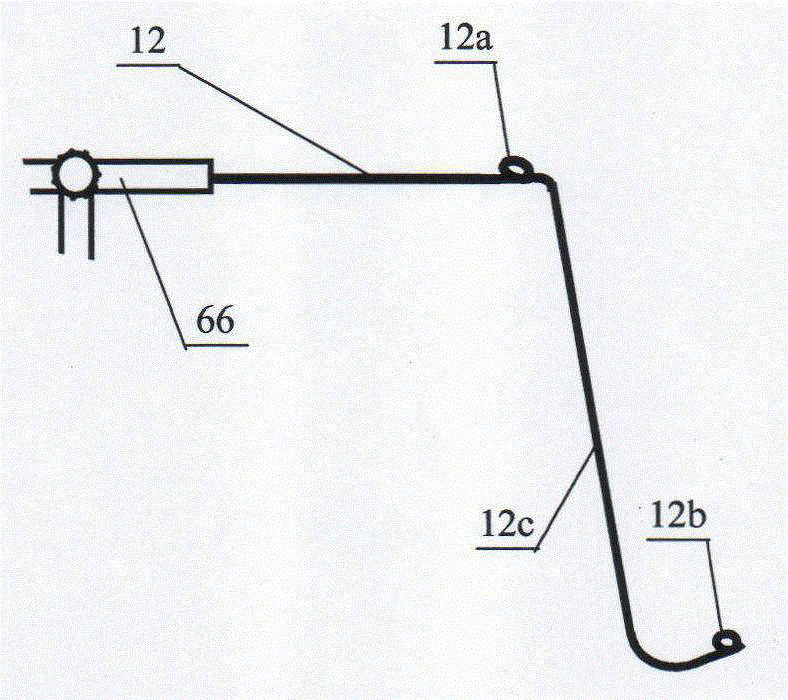

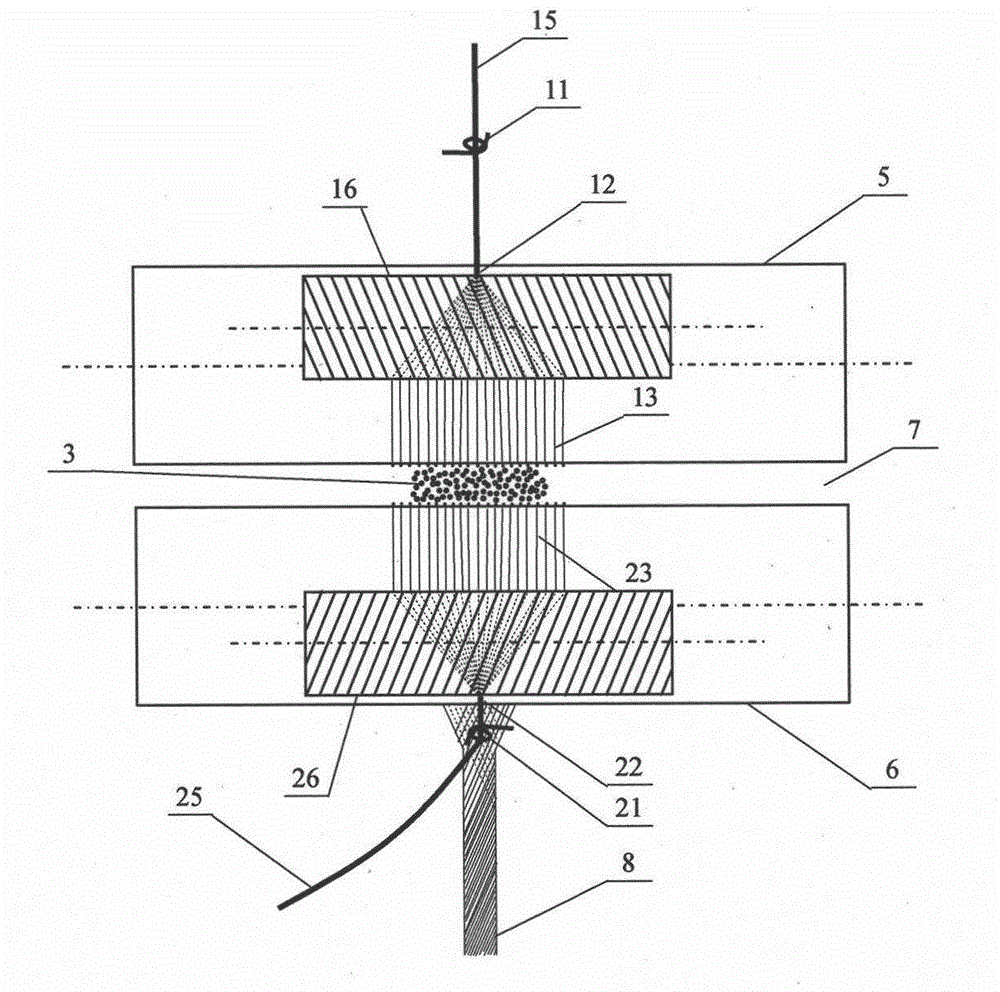

Three-shafting composite spinning method of constant-tension double-filament adjoining and twisting triangular zone and application thereof

The invention relates to a three-shafting composite spinning process of a constant-tension double-filament adjoining and twisting triangular zone and application thereof. The process comprises the steps of adopting a double-tension wheel to enable two beams of filaments to synchronize with the three-shafting in a way of adjoining left and right sides of a short fiber whisker strip via constant tension to be fed into a front roller through a beam concentrator; after outputting from a jaw of the front roller, wrapping the two beams of the filaments on the short fiber whisker strip in the twisting triangular zone to form a smooth composite yarn with the short fiber whisker strip wrapped by the double filaments basically in a no self-twisting manner. The process is simple and practical, can efficiently improve spinning efficiency and high branching of fibers with worse spinnability and reduce flying, scraps and fluffs in the spinning process, and is suitable for composite spinning of high-count smooth yarns and superfine yarns of shorter, weaker and ultra-short fibers.

Owner:DONGHUA UNIV

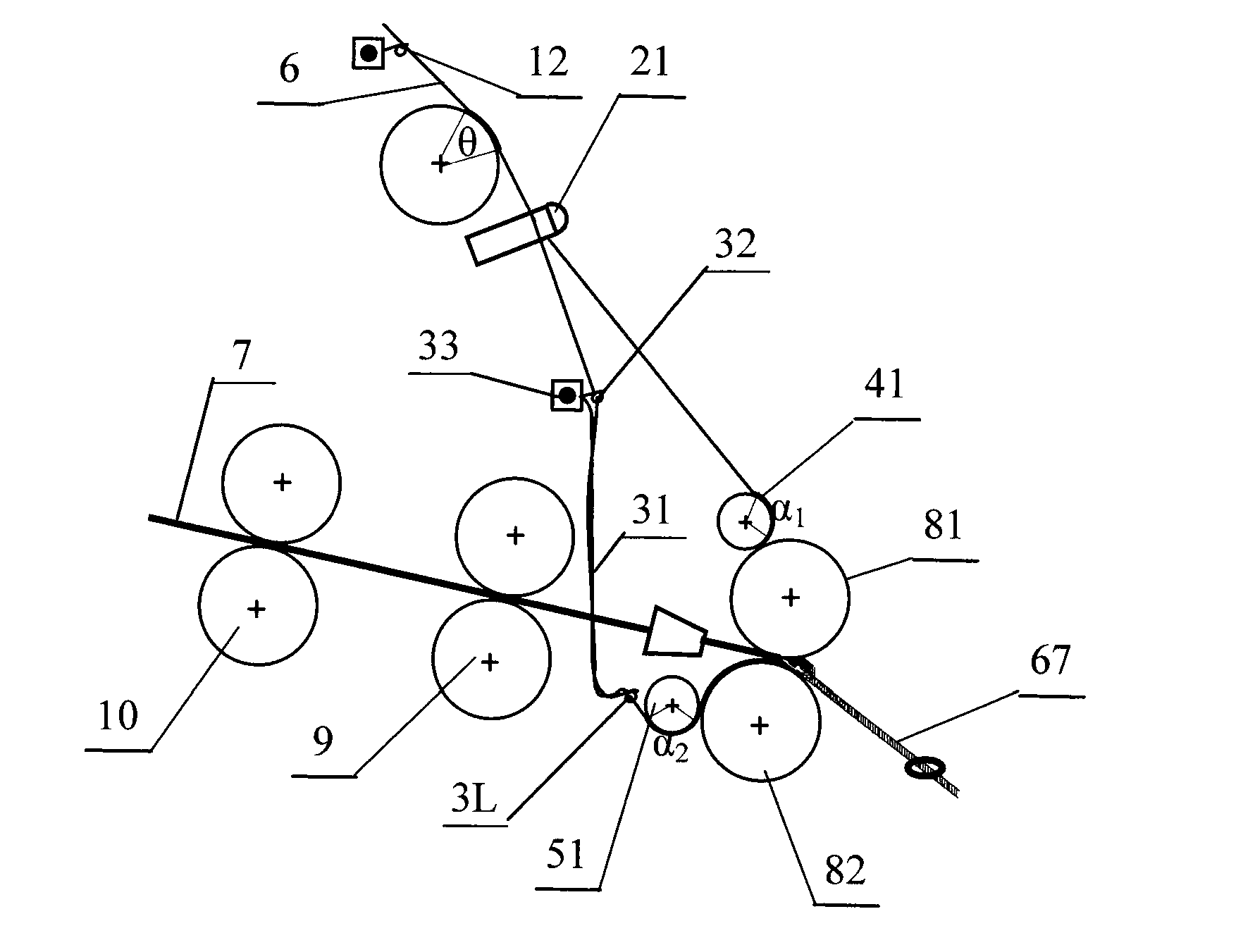

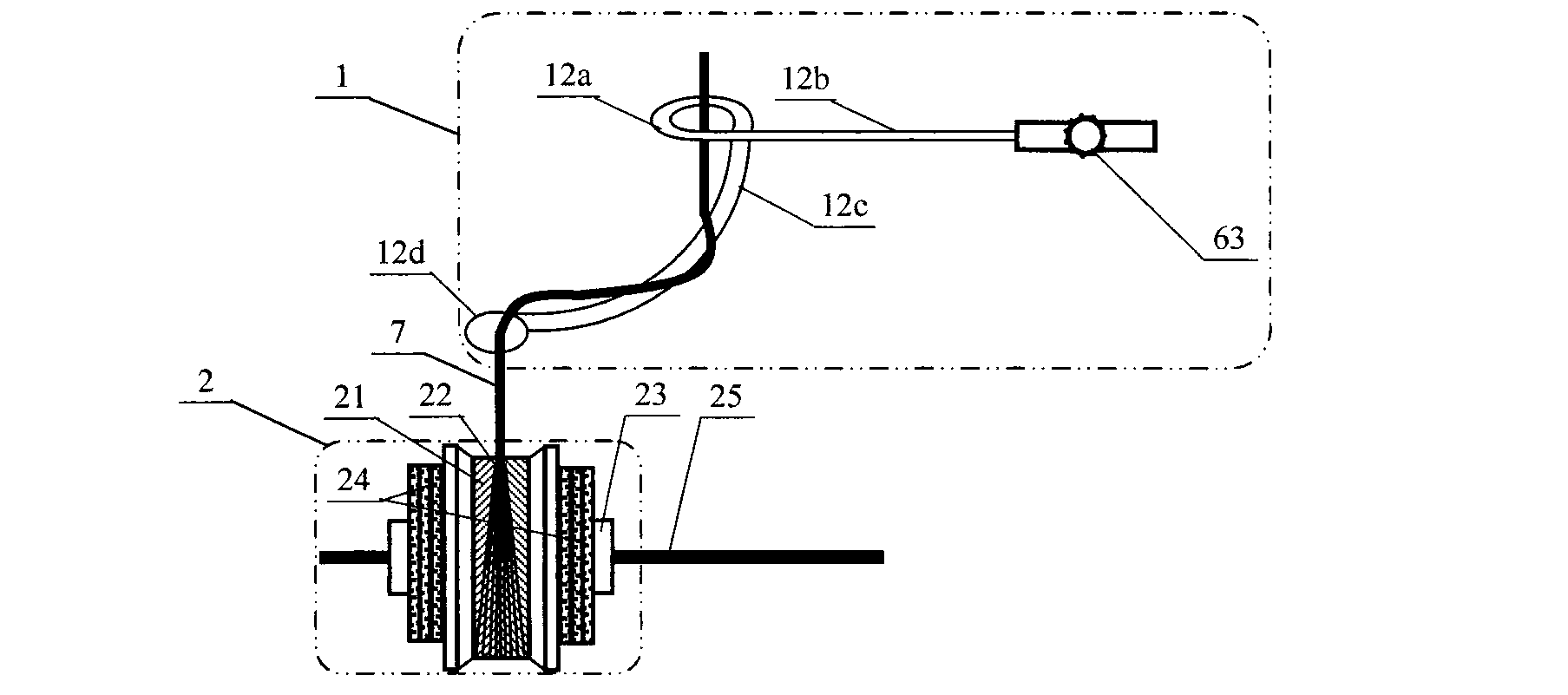

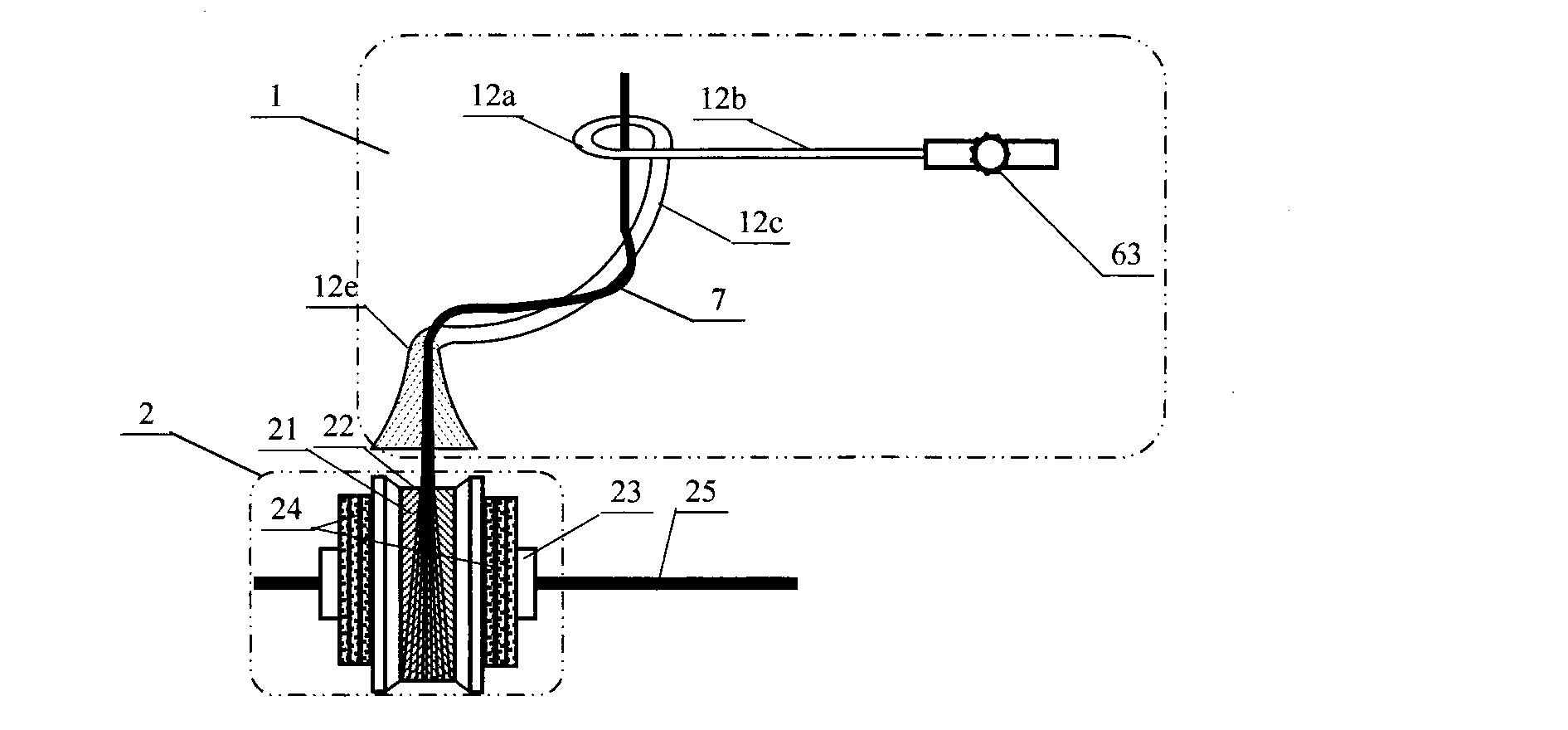

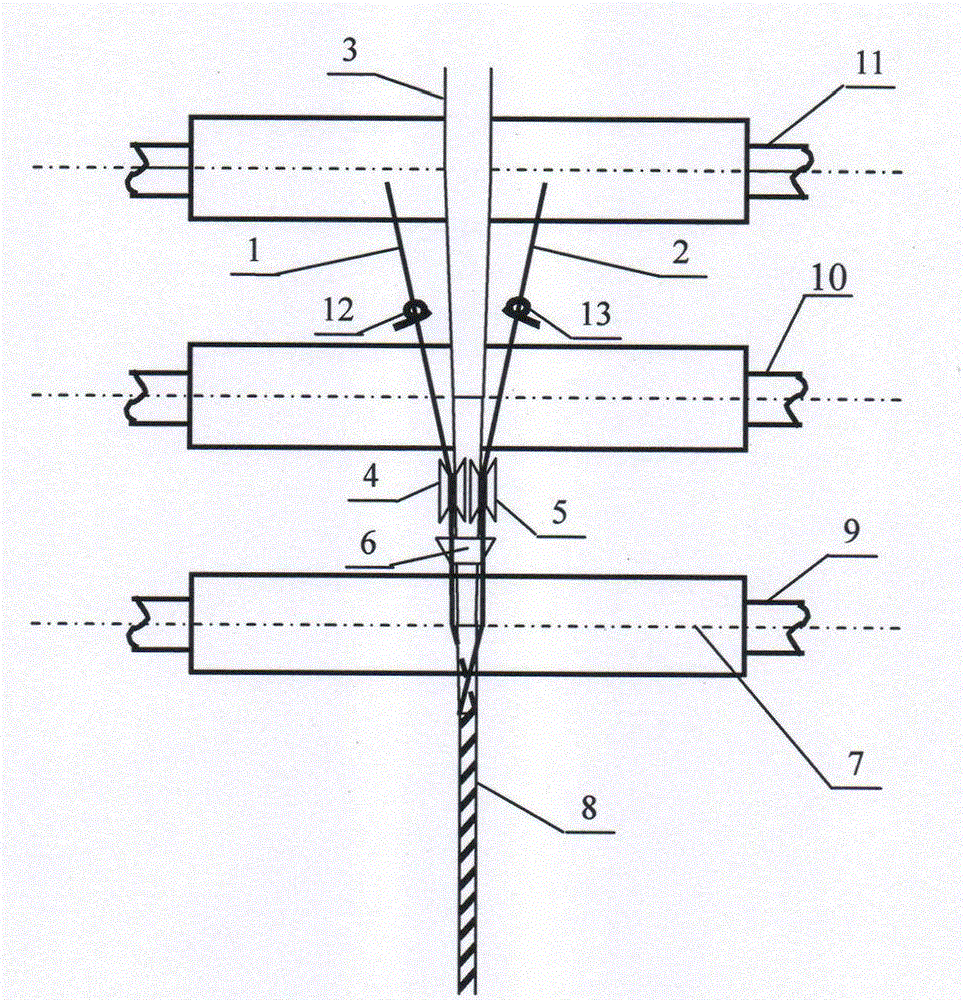

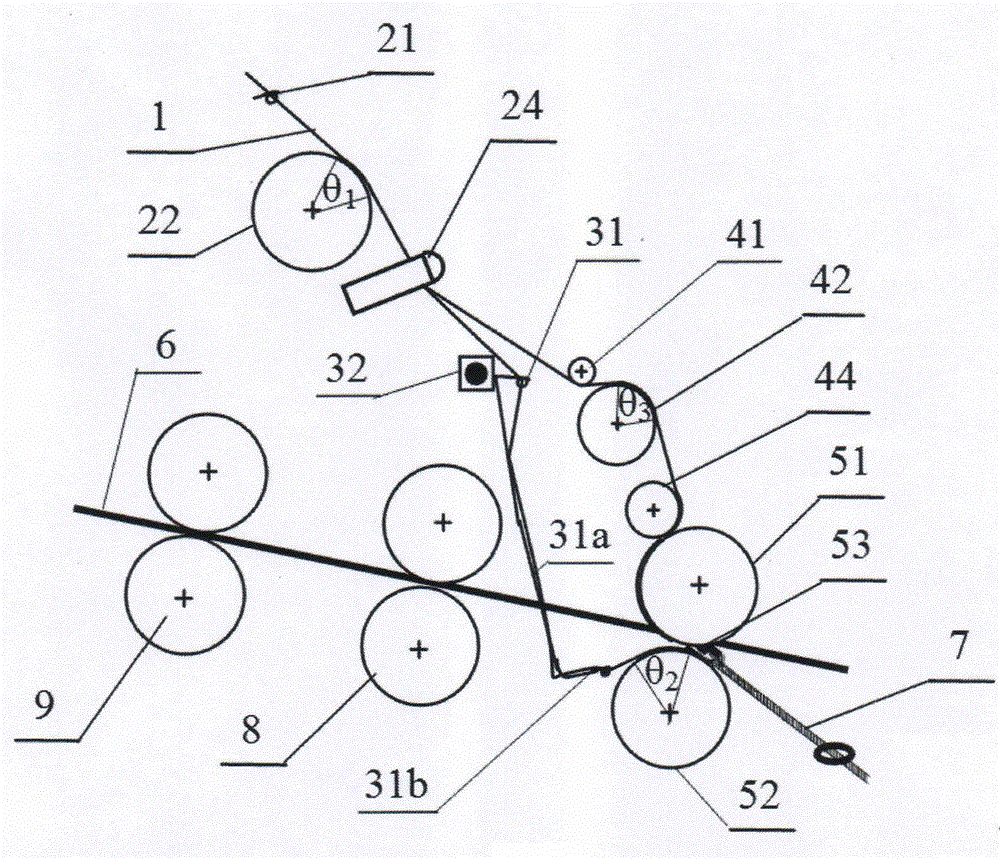

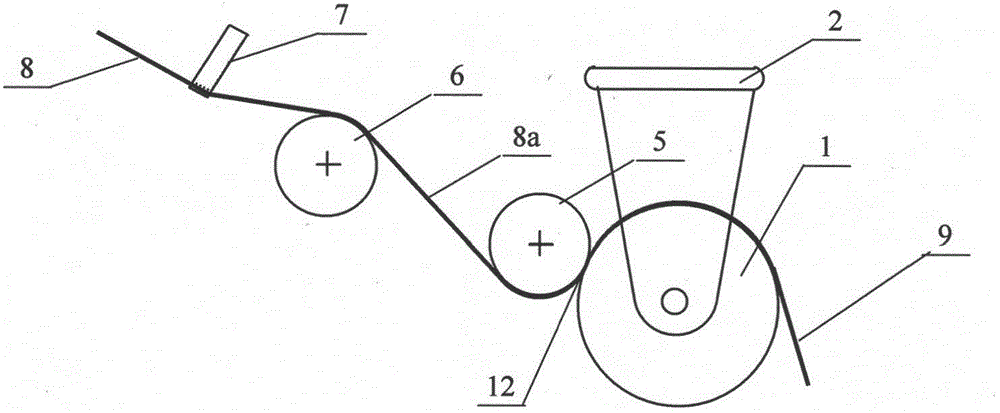

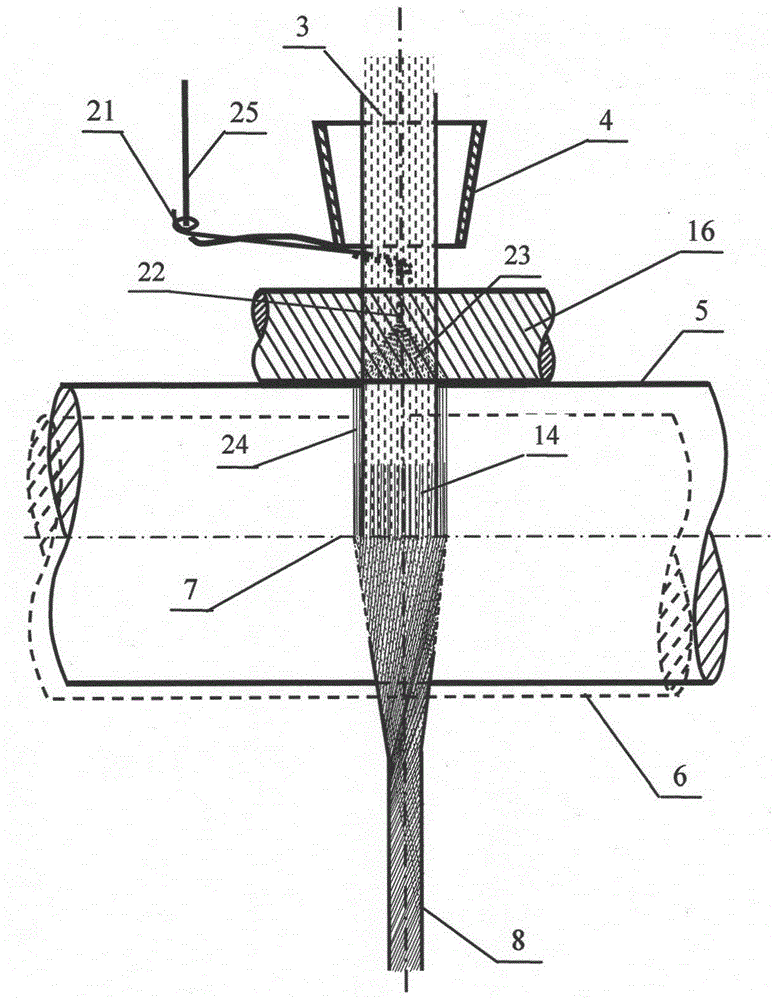

Smooth composite spinning mechanism and method of short fiber whisker strip clamped by double filaments via unequal tension

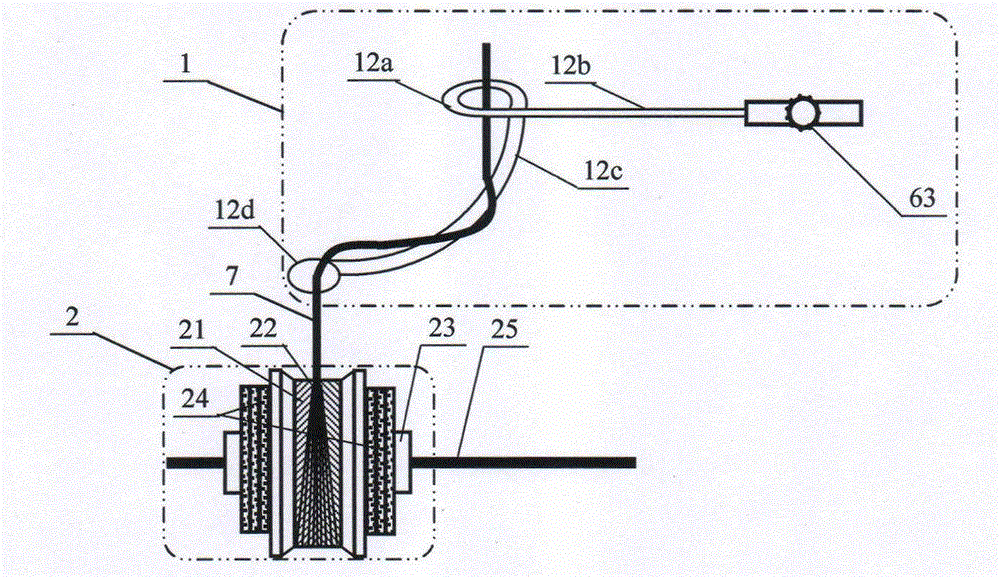

The invention relates to a smooth composite spinning mechanism, method and application of a short fiber whisker strip clamped by double filaments via unequal tension. The mechanism is composed of a tension disk used for locating a tension filament and controlling tension thereof, a yarn guide hook used for locating a low-tension filament and a holding roller used for keeping the tension. The composite spinning method comprises the steps of: synchronously feeding the tension filament, the low-tension filament as well as the short fiber whisker strip into a front roller to enable the short fiber whisker strip to be wrapped by the two filaments in a traction zone; and forming a three-shafting spinning yarn with the short fiber whisker strip covered by the tension filament from the upside and support by the low-tension filament from the downside, wherein the composite yarn is a smooth composite yarn which is formed by spirally twisting the tension filament and the short fiber whisker strip and externally coating the low-tension filament. The mechanism is light, practical, convenient to install, controllable and adjustable, can produce yarns with steady structure and is suitable for composite spinning of high-count smooth yarns and superfine yarns of short fibers.

Owner:DONGHUA UNIV

Method for carrying out stone washing on soft coarse-wooled fabric

ActiveCN103114472ASoft touchImproves shrink resistanceBiochemical fibre treatmentDry-cleaning apparatus for textilesFiberYarn

The invention discloses a method for carrying out stone washing on a soft coarse-wooled fabric, aiming to providing a method for carrying out stone washing on a soft coarse-wooled fabric with a distressed, faded, clear and natural surface and less villi, wherein the fabric is high in resilience and soft in handfeel, the colors of the front and back surfaces of the fabric have a large contrast, and the fabric has a retro nostalgic feeling. The method is characterized by comprising the steps of carrying out mercerization on fibers, spinning yarns, spinning a fabric, carrying out curing and shrink-resistant treatment on the fabric, forming a garment, carrying out dyeing and stone washing on the garment, and drying and tidying up the garment. According to the method, through carrying out shrink-resistant treatment by two times in the earlier stage and carrying out stone washing by using vesuvianite into which proteases and a detergent are soaked, the defect that common wool fabrics have a serious milling phenomenon after being subjected to sand washing is successfully controlled, and excessive damage on fabrics in the process of doing old is effectively prevented, thereby prolonging the service life of garments.

Owner:山东神州毛纺织有限公司

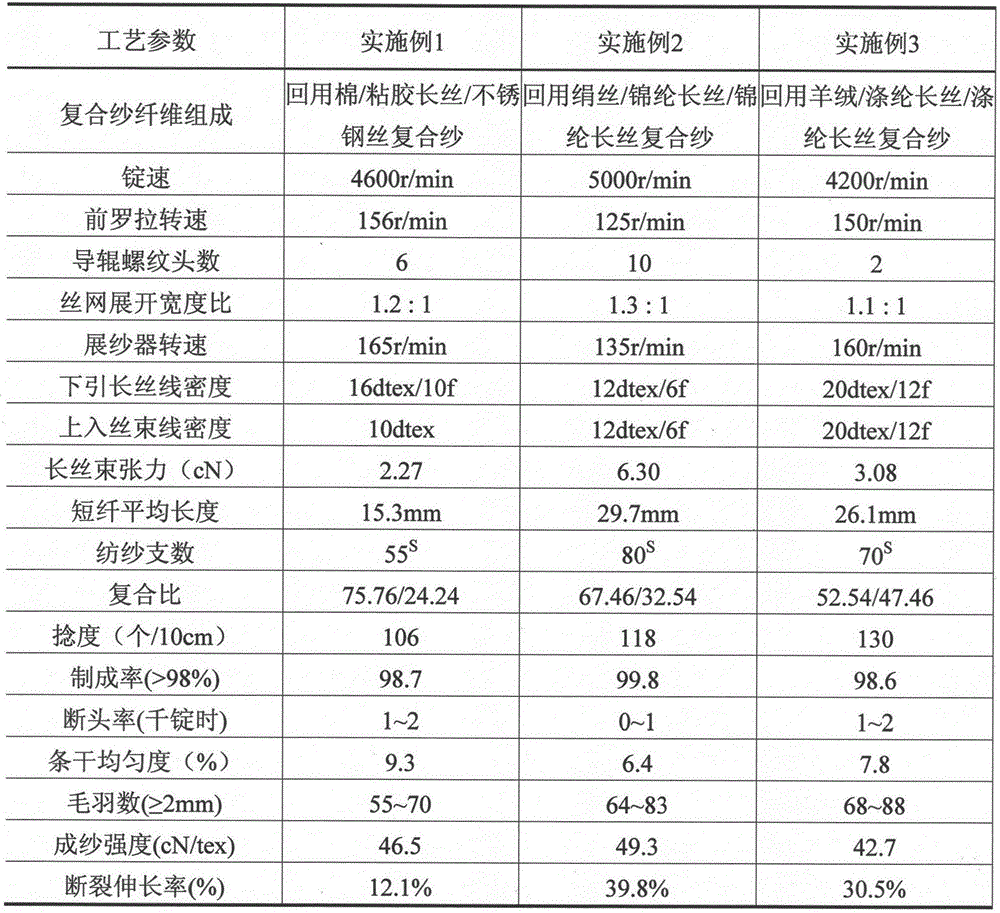

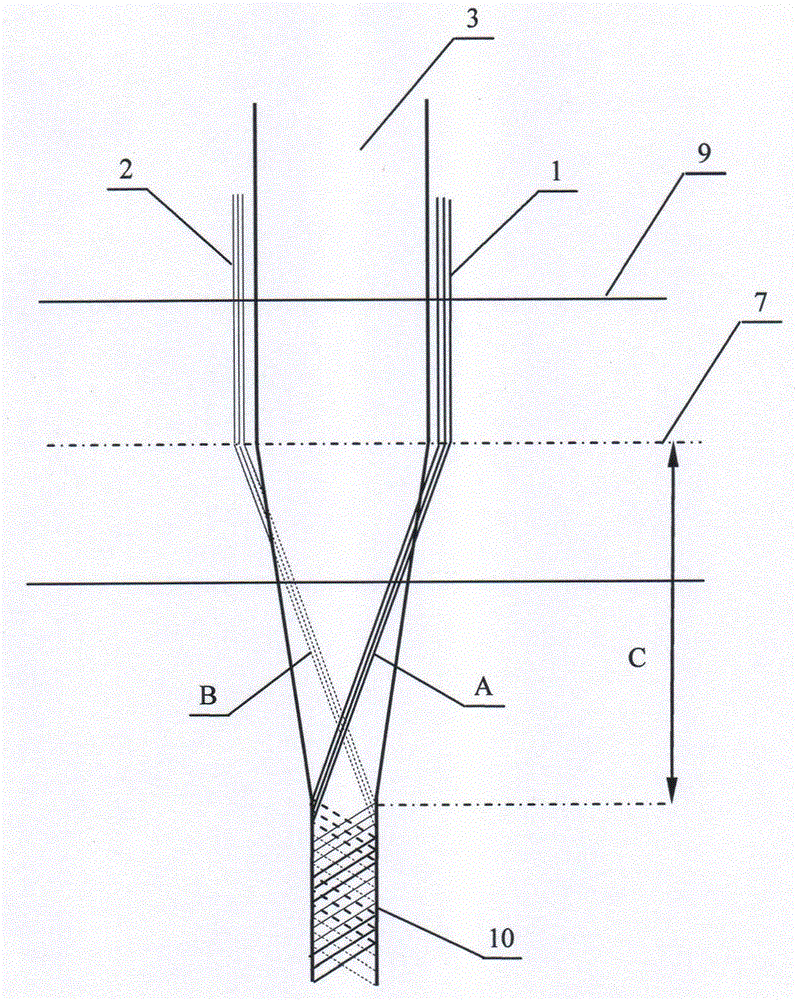

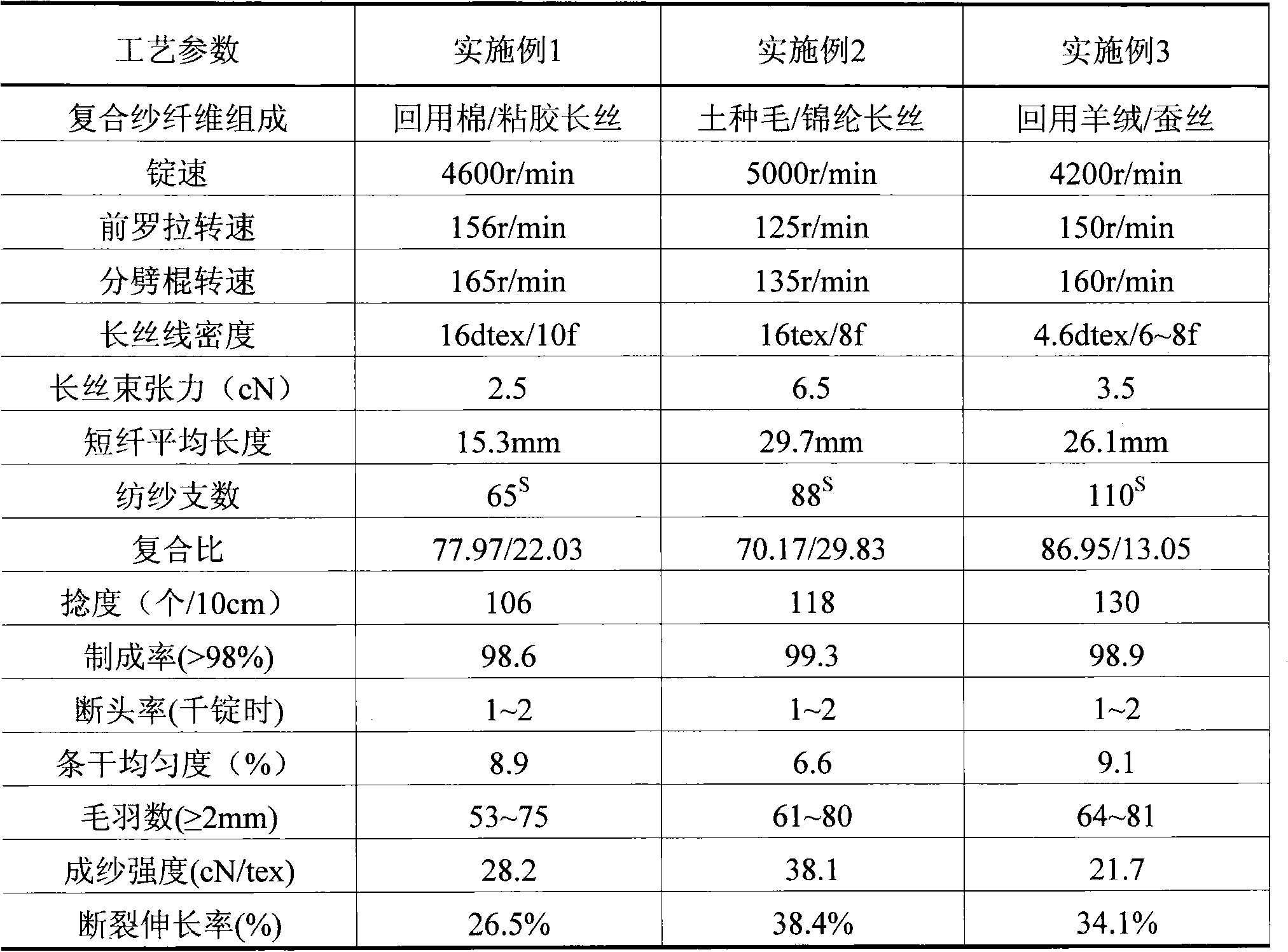

Non-equal convergent point double tow-screen composite yarn, spinning method and application

The invention relates to a non-equal convergent point double tow-screen composite yarn, a spinning method and application of the composite yarn. The composite yarn with six lines of shafting is formed by at least compositing three convergence shafts, double tows and screens at least with two convergent points not on the same level and staple fiber strands and can be used for weaving fabrics and high-grade fine fabrics which have clear textures and high strength, are soft and wear-resistant, are resistant to fuzzing and pilling and are beautiful and comfortable. The spinning method realizing the composite yarn is characterized by adopting a splitting machine with yarn spreading function and left and right yarn spreading machines and splitting two filaments into 22 tows asymmetrically with the splitting machine, wherein two tows are directly fed into a front roller jaw and another two tows enter respective yarn spreading machine to be spread into screens and then are fed into the front roller jaw and form the multi-stage converging and compositing double tow-screen composite yarn which reinforces tows of the two staple fiber strands and protects the screens in the twisting triangular space. The method is suitable for spinning protective, soft and smooth high-count composite yarns with super-staple fibers, fibers liable to drop of chips, fibers liable to flying and shorter and weaker reclaimed fibers.

Owner:DONGHUA UNIV

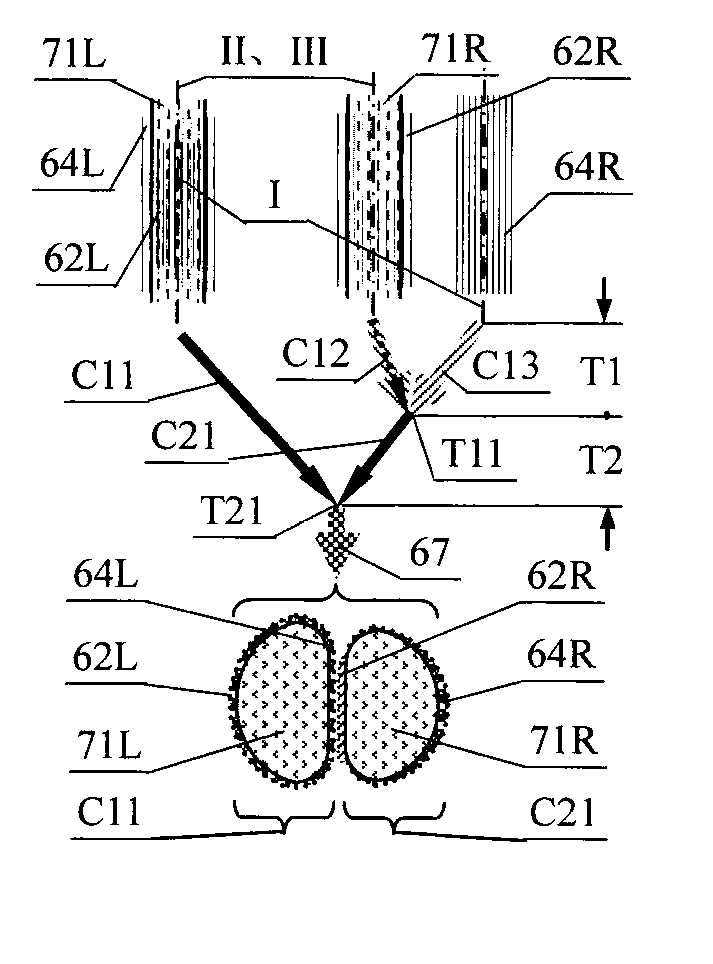

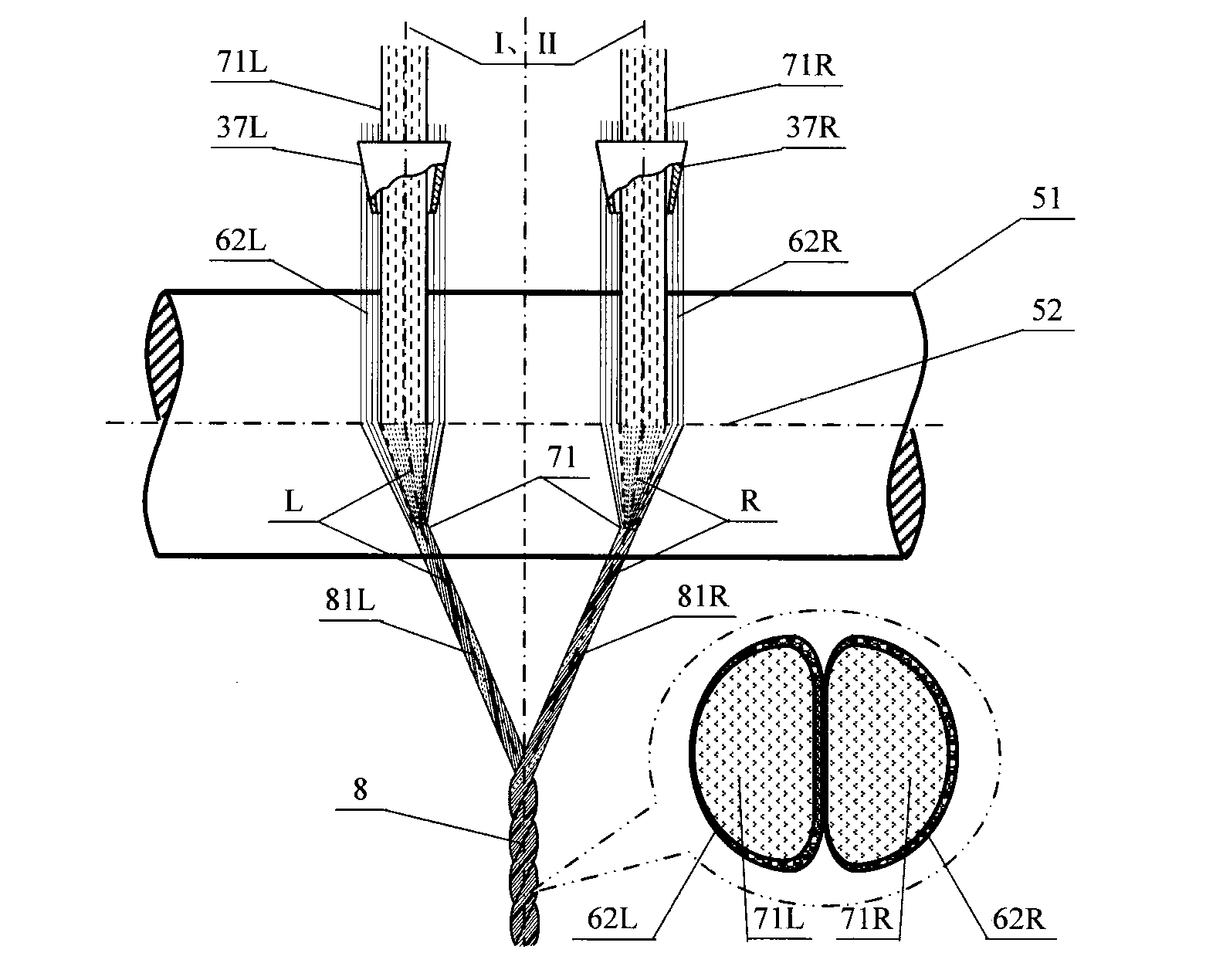

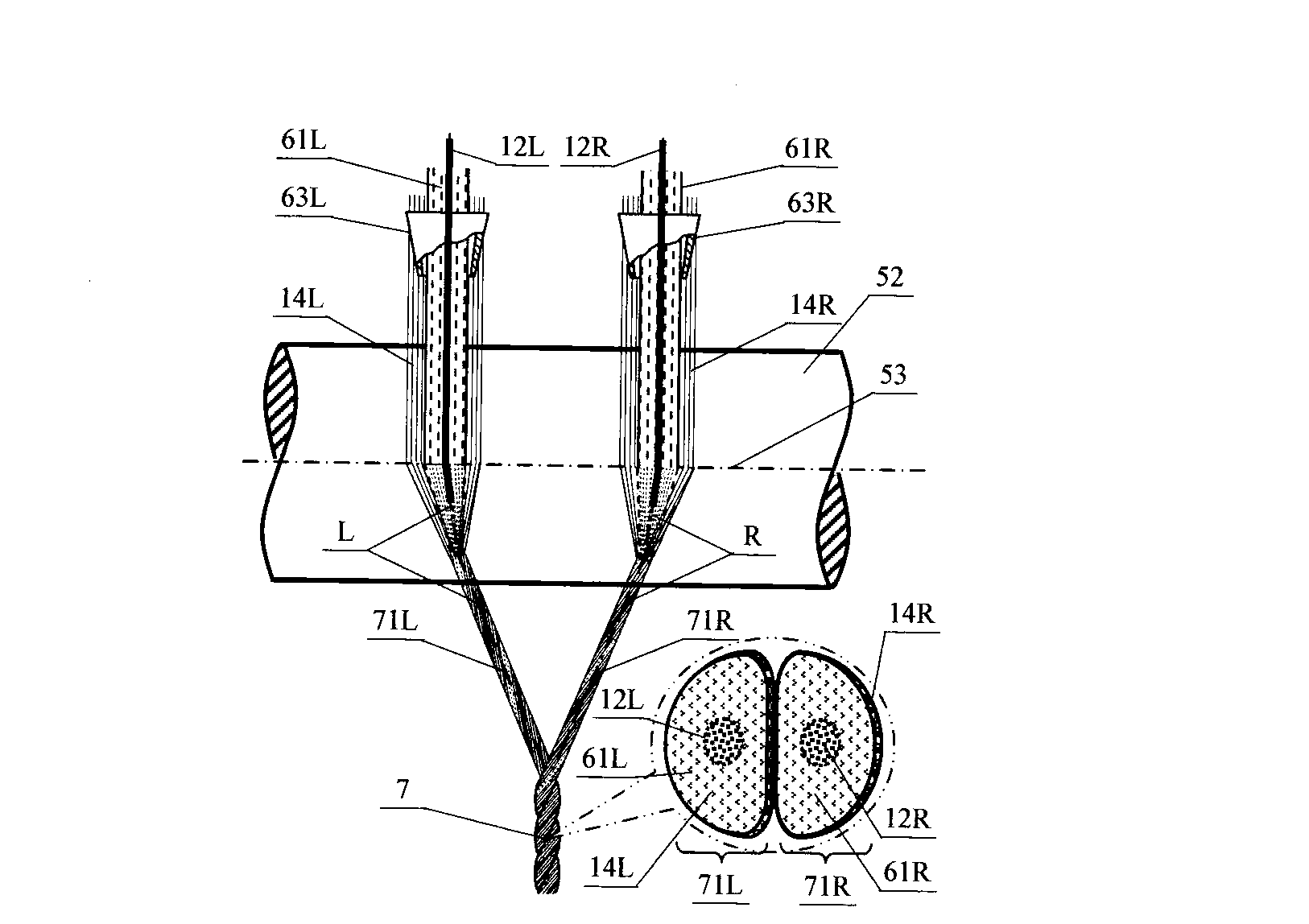

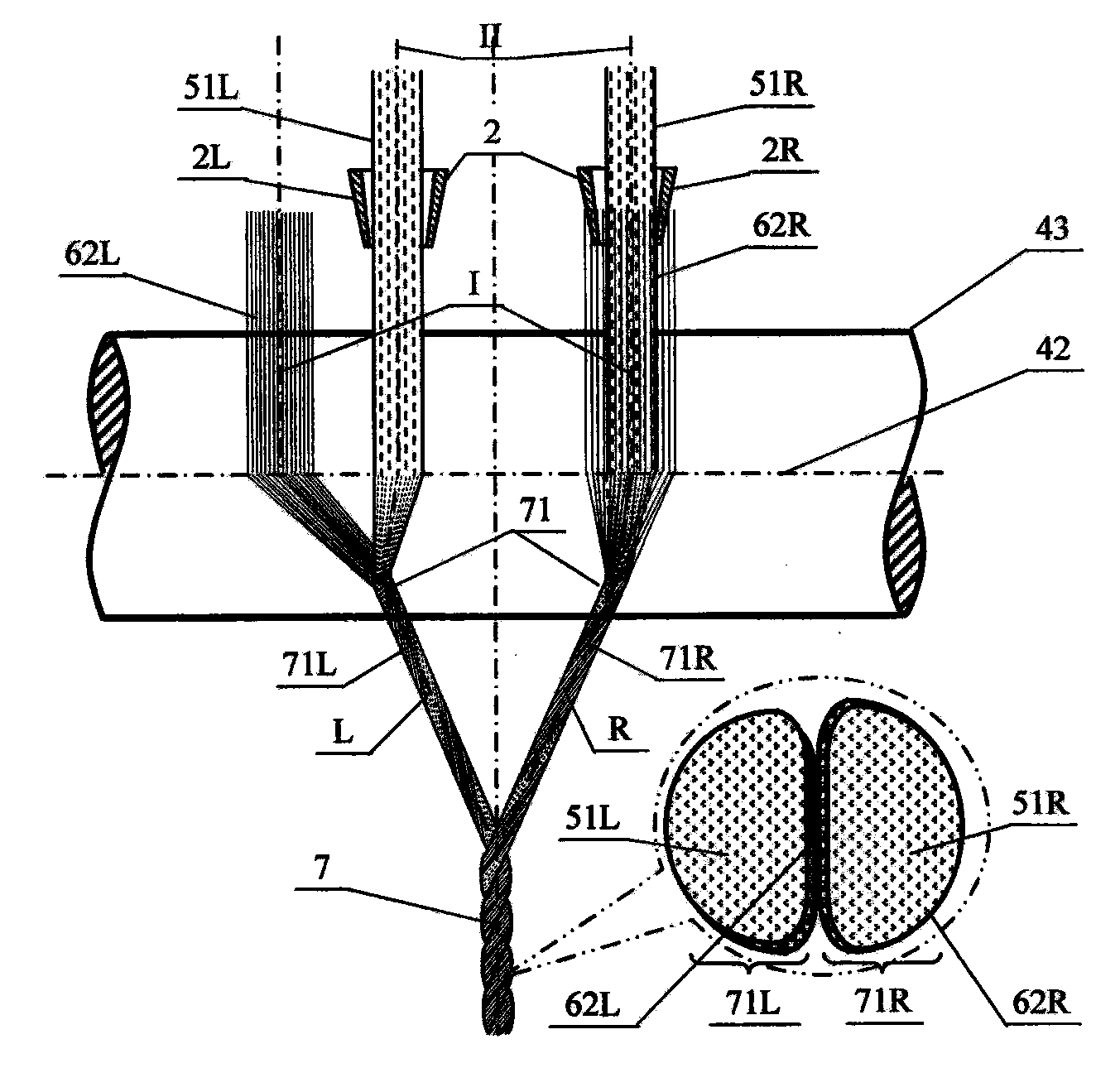

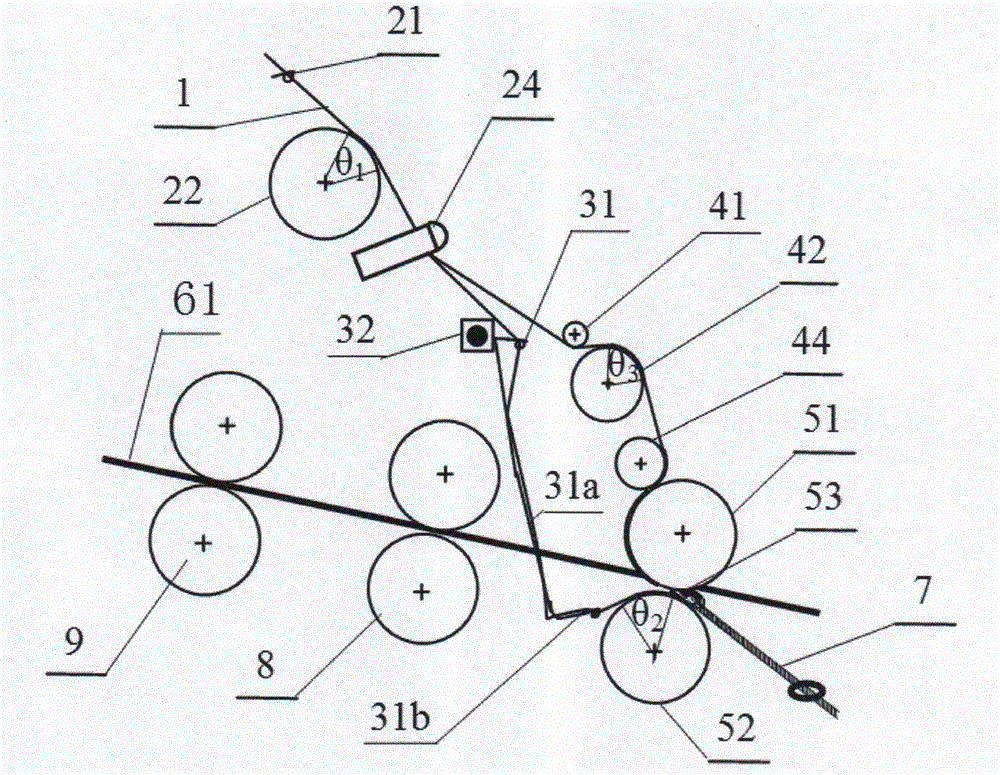

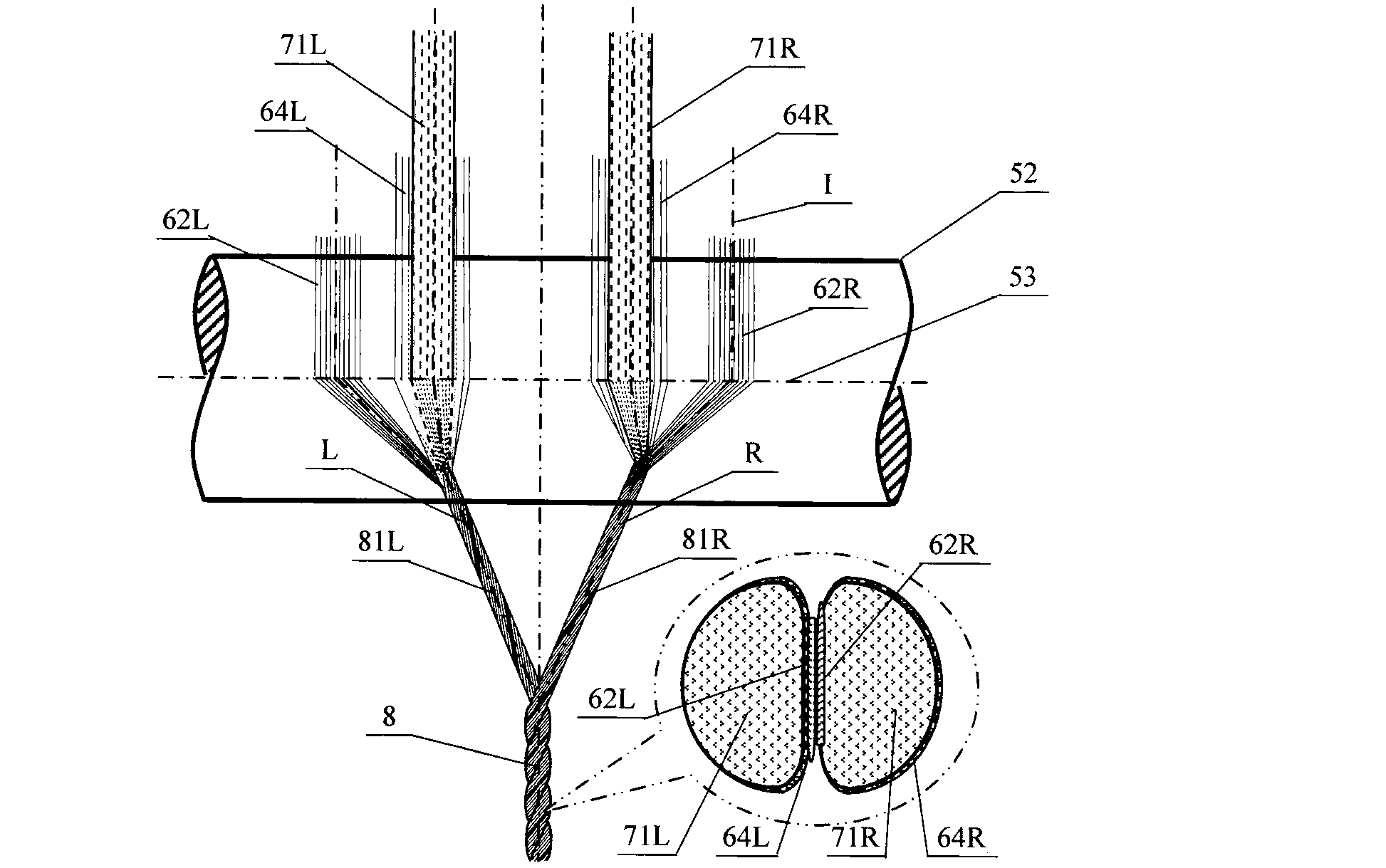

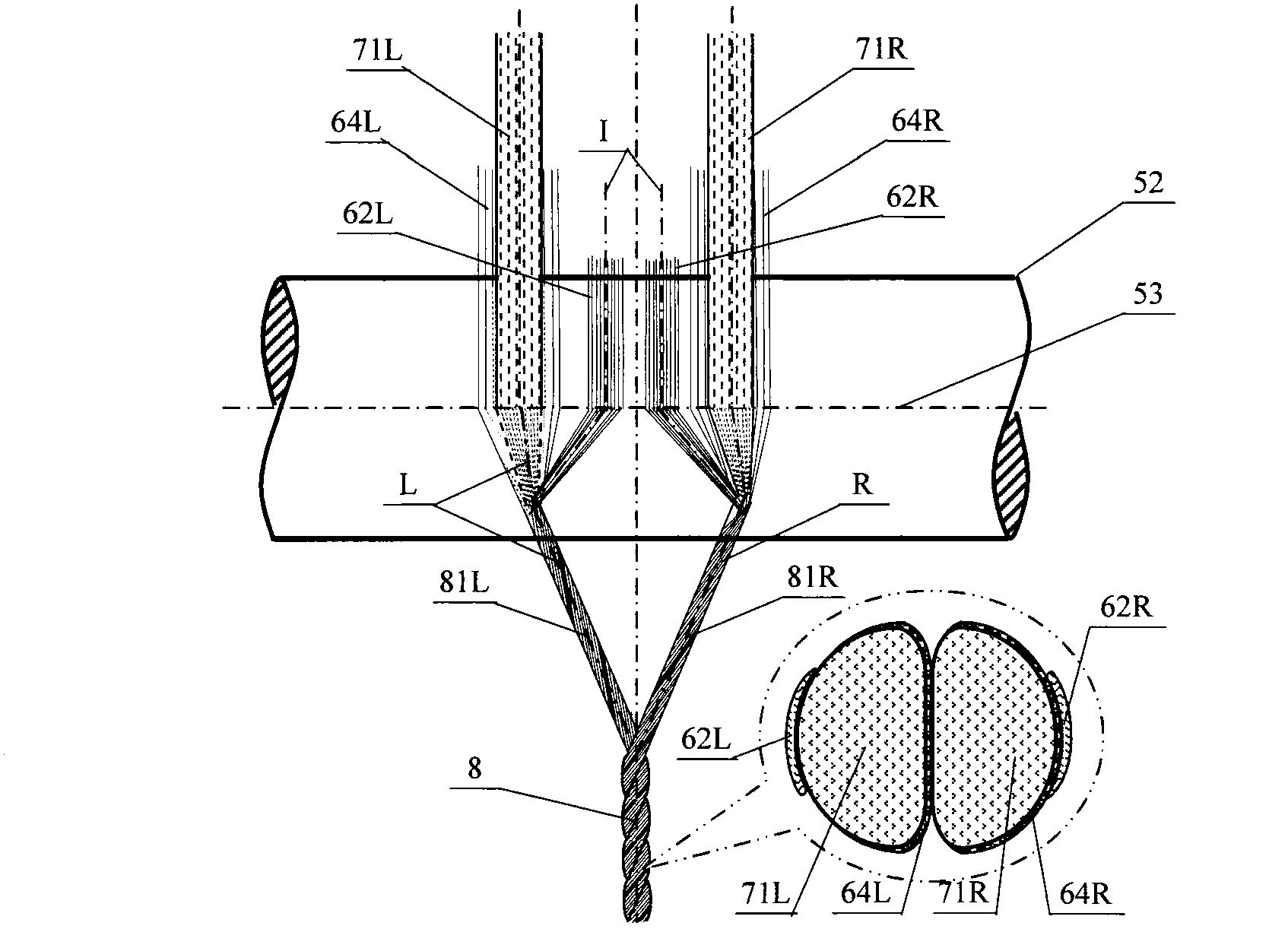

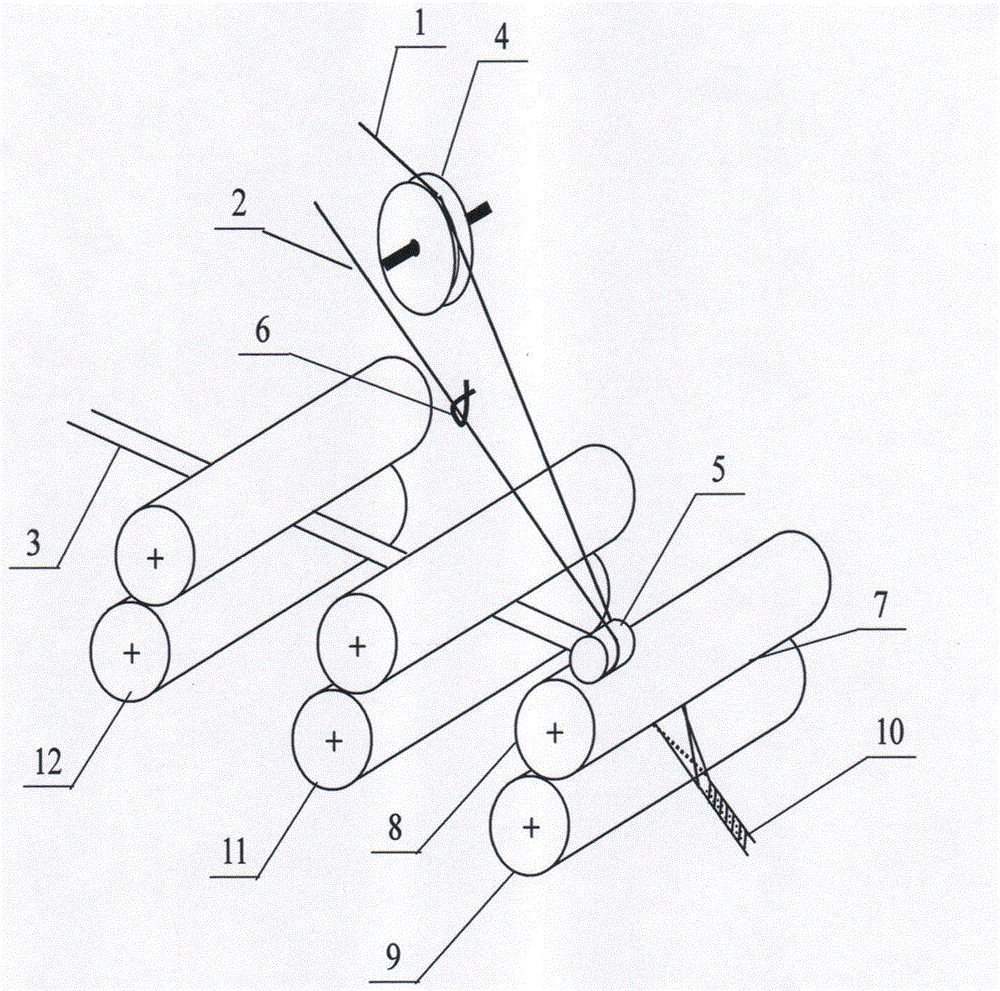

Silk net covering type 2*2 axis composite yarn, spinning method and application

The invention relates to a silk net t covering type 2*2 axis composite yarn, a spinning method and application. The composite yarn is 2*2 axis composite yarn which is formed by covering and compositing two short fiber whiskers on two silk nets respectively and comprises a net wrapping form, a net wrapping net covering form and a net covering form. The composite yarn in the net wrapping form, the net wrapping net covering form and the net covering form can be woven into textiles which are clear in texture, soft and wear-resistant, high in intensity, and attractive in appearance and comfortable and resist fluffing and pilling and high-grade fine fabric. According to the spinning method for the composite yarn, twizzles, bunchers and filament spreading devices are arranged on a ring spinning machine, two bundles of filaments are centered by a left twizzle and a right twizzle, then enter the respective filament spreading devices and are spread so as to form two covering silk nets; the two covering silk nets and the short fiber whiskers which are positioned by the bunchers enter a front roller jaw synchronously in upper and lower layers, the respective short fiber whiskers are wrapped and wound at a twisting triangular area, and the respective short fiber whiskers and the filaments are composited to form the composite yarn. The method is suitable for spinning soft, smooth and clean, high-count protective composite yarn of ultrashort fibers with high scrap falling and flying possibility and weak reclaimed fibers.

Owner:DONGHUA UNIV

Unequal rendezvous point spinning method of asymmetrical beam splitting spread filament, composite yarn and application

The invention relates to an unequal rendezvous point spinning method of an asymmetrical beam splitting spread filament, a composite yarn and application. The composite spinning method comprises the steps of: adopting a splitter and a filament spreading device; and splitting two beams of filaments into 2*2 beams including two upstream beams and two downstream beams asymmetrically through the splitter; enabling the four beams to enter into respective filament spreading devices to form filament meshes; then feeding the filament meshes at different positions; wrapping a short fiber whisker strip in a twisting triangular zone and multi-level converging to compound the filament mesh wrapping composite yarn. The method is suitable for spinning of protective, soft, smooth and high-count composite yarns of fibers which are ultra-short, easy to drop scraps and easy to generate flying and shorter and weaker fibers. The obtained composite yarn is a filament mesh wrapping six-shafting composite yarn at least having three convergent shafts and at least two rendezvous points being not on the same horizontal line. The composite yarn has four ways of the convergent shafts and can be used for weaving soft, abrasion-resistant, beautiful and comfortable textiles with clear texture, high intensity and pilling resistance and high-level fine fabrics.

Owner:DONGHUA UNIV

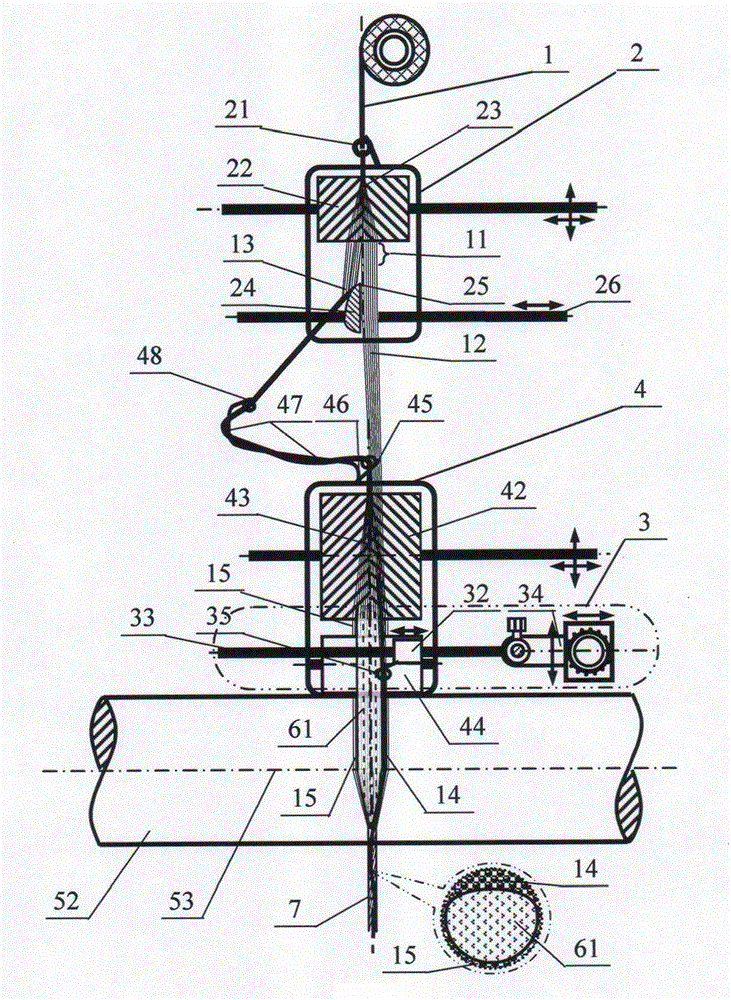

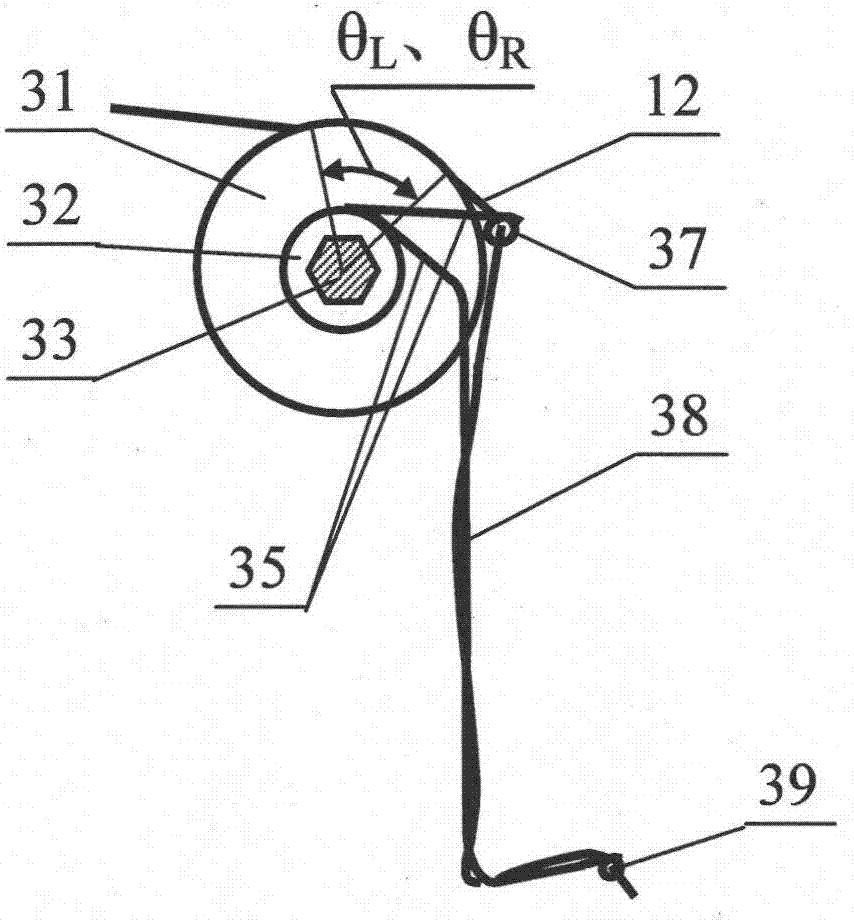

Coaxial bidirectional filament spreading device of beam-splitting filament and application

The invention relates to a coaxial bidirectional filament spreading device of a beam-splitting filament and application. The filament spreading device is composed of a centering yarn guide hook, a spreading disk for spreading the filament beam, a splitting separator, a filament spreading roller for spreading a splitting filament layer in a bidirectional way, a driving roller at the same speed as a front roller and the like, is connected to a fixed frame and is mounted on a ring throstle through the fixed frame. A method for spreading the beam-splitting filament coaxially and in the bidirectional way comprises the steps of: locating a filament on a central line of a flat bottom groove of the spreading disk by the centering yarn guide hook and winding on the spreading disk to finish the spreading of the filament beam; then splitting the filament symmetrically by the splitting separator to form two filament beam layers with a certain interval, enabling the two filament beam layers to enter into respective one-way filament spreading zones and respectively spreading the filament beam layer towards left and right under the action of a screw thread groove to form a filament mesh; and outputting the filament mesh by surrounding and being close to a driving roller of the front roller. The filament spreading device can be applied to spinning of protective type soft, smooth, high-count composite yarns and superfine branches of fibers which are ultra-short, easy to drop scraps and easy to generate flying and shorter and weaker fibers.

Owner:DONGHUA UNIV

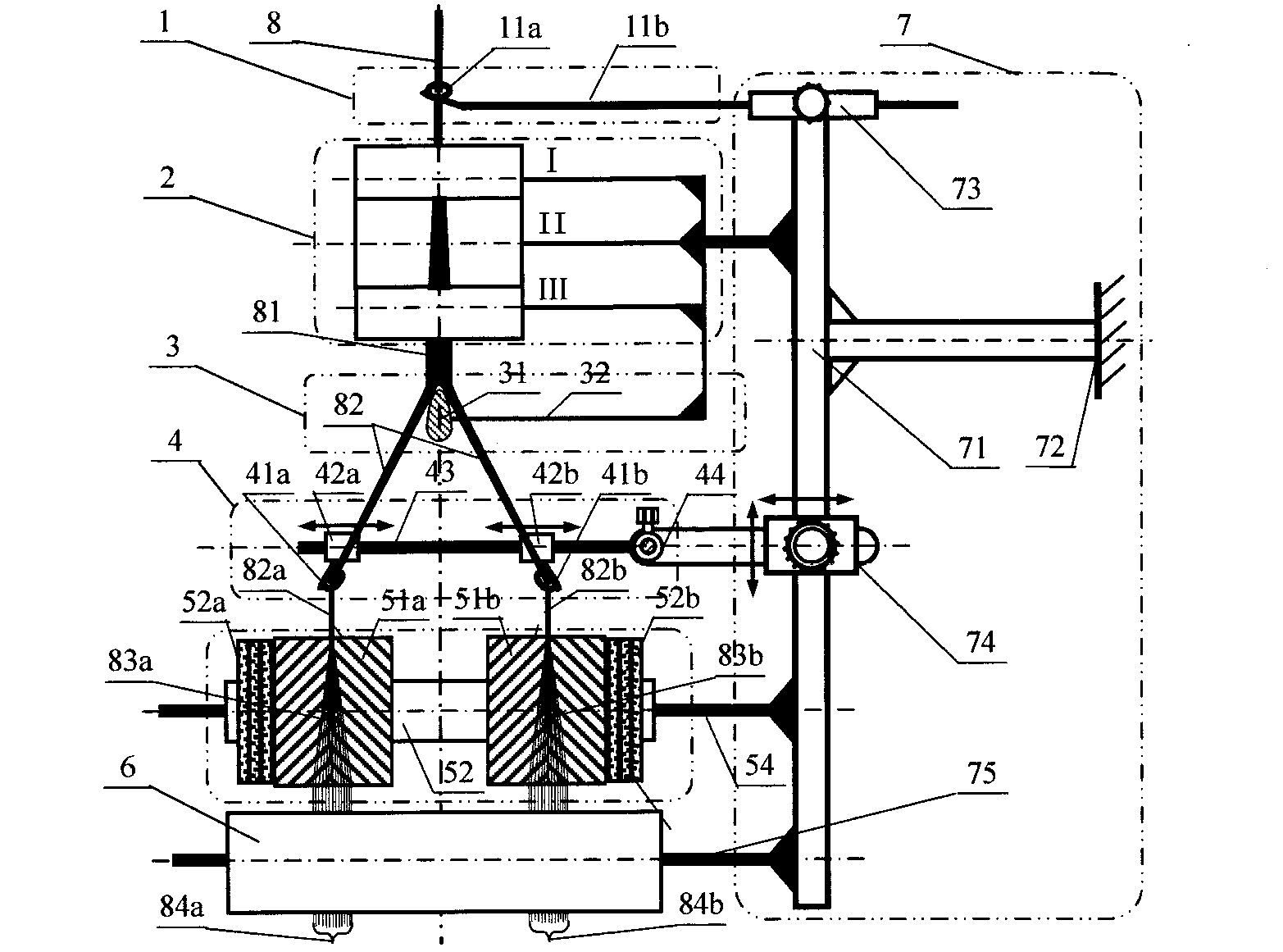

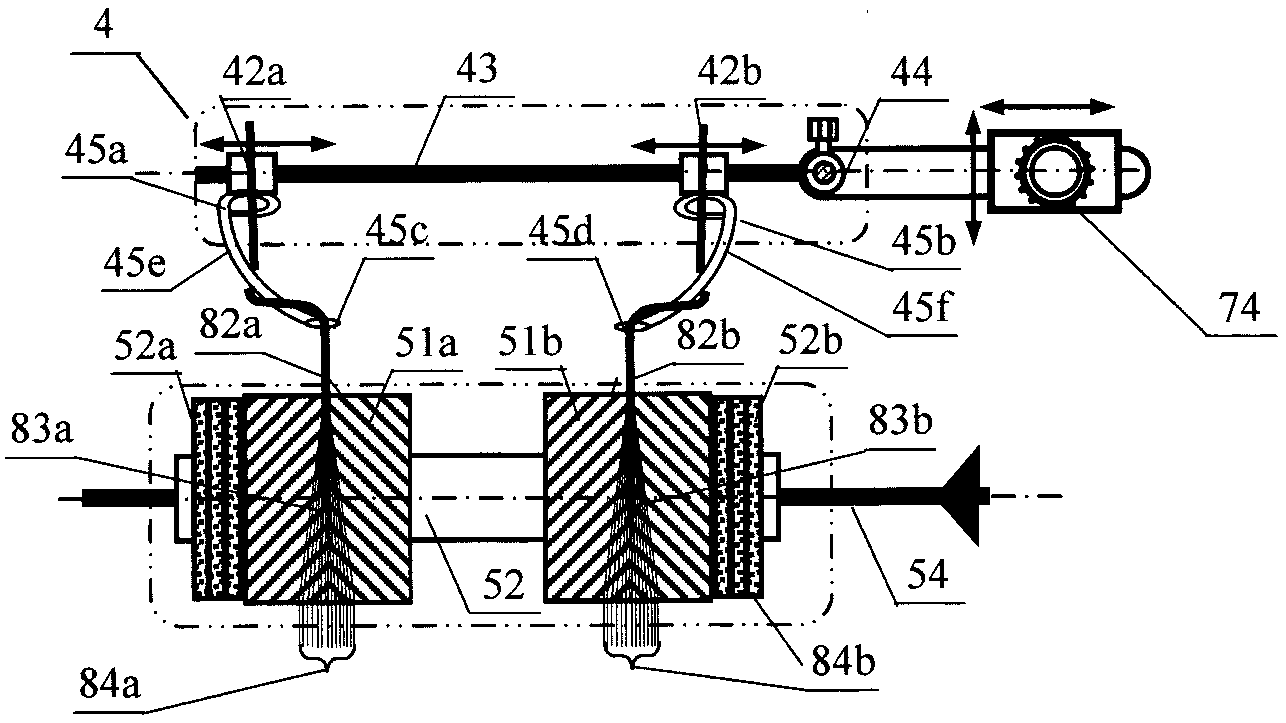

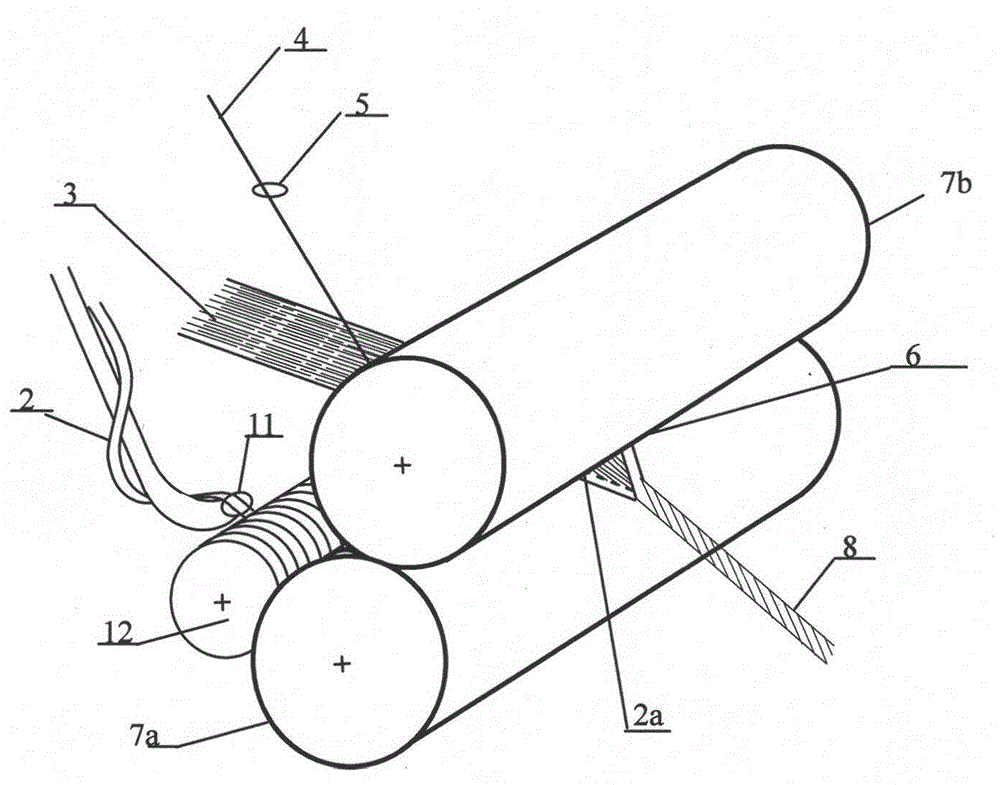

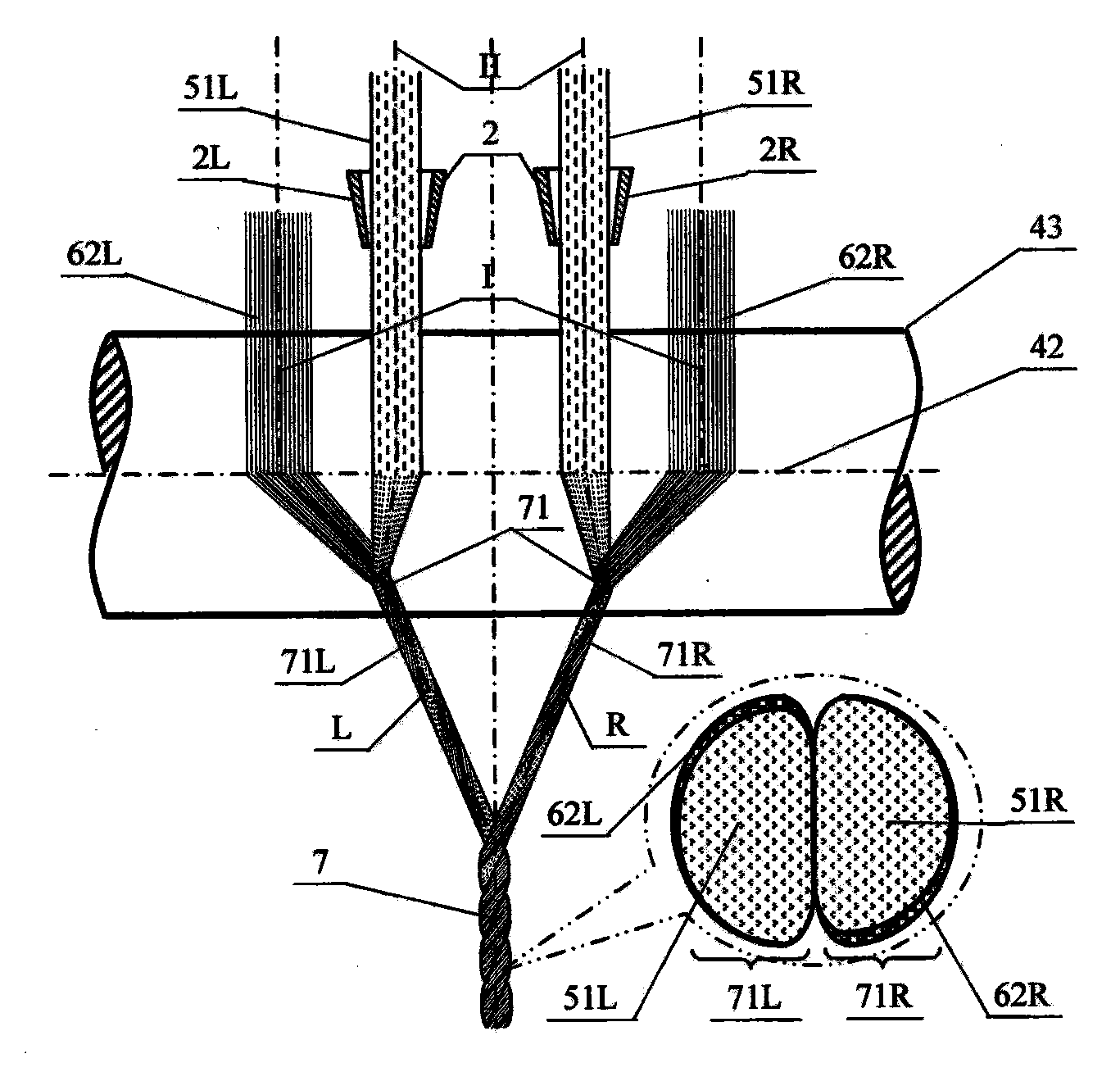

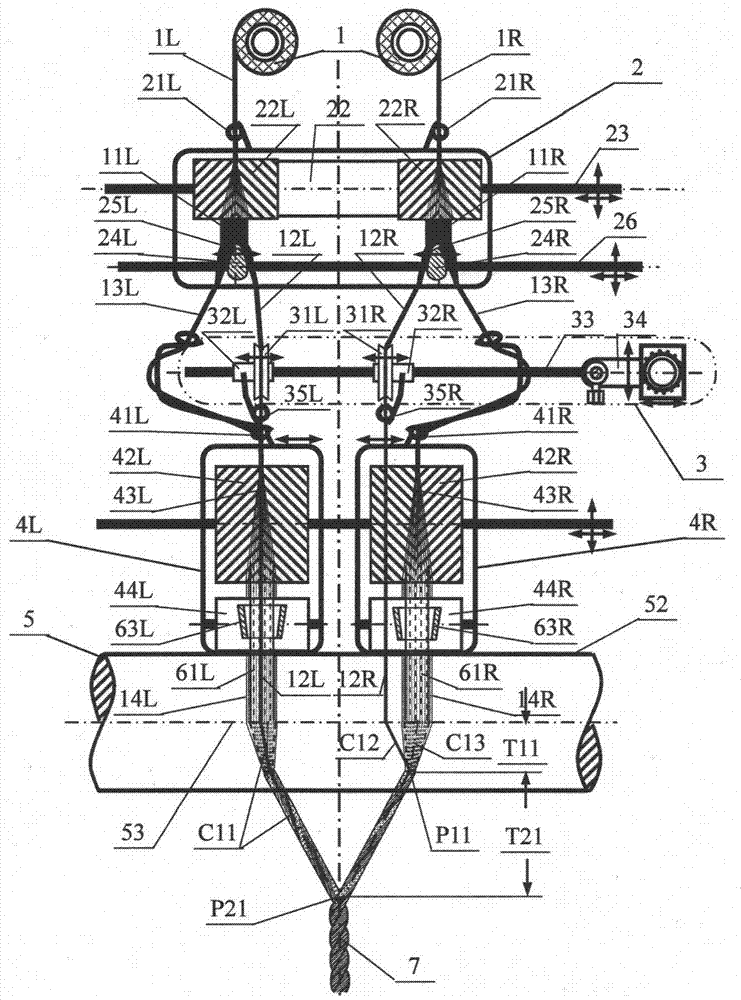

Symmetrical beam-splitting filament-spreading double-lower support 2*2 shafting composite yarn, spinning method and application

The invention relates to a symmetrical beam-splitting filament-spreading double-lower support 2*2 shafting composite yarn, a spinning method and application. The composite yarn is a 2*2 shafting mesh wrapping, mesh wrapping and coating and mesh coating composite yarn which is compounded after two filament meshes respectively support and wrap short fiber whisker strips from downsides; and the composite yarn can be used for weaving soft, abrasion-resistant, beautiful and comfortable textiles with clear texture, high intensity and pilling resistance and high-level fine fabrics. The method for producing the composite yarn comprises the steps of: adopting a yarn guide hook, a splitter, a beam concentrator and filament spreading devices all of which are mounted on a ring throstle; after splitting the filament into two beams by using the splitter, downwards guiding the beams by left and right filament guide hooks and feeding the beams into respective filament spreading devices for filament spreading in a centering manner and forming tow paths of lower-supporting filament meshes; enabling the spread filaments and the short fiber whisker strips located by the beam concentrator to enter into the front roller in a manner of upper and lower layers; wrapping respective short fiber whisker strips in a twisting triangular zone and compounding to form the composite yarn. The method is suitable for spinning of protective, soft, smooth and high-count and superfine composite yarns of fibers which are ultra-short, easy to drop scraps and easy to generate flying and shorter and weaker fibers.

Owner:DONGHUA UNIV

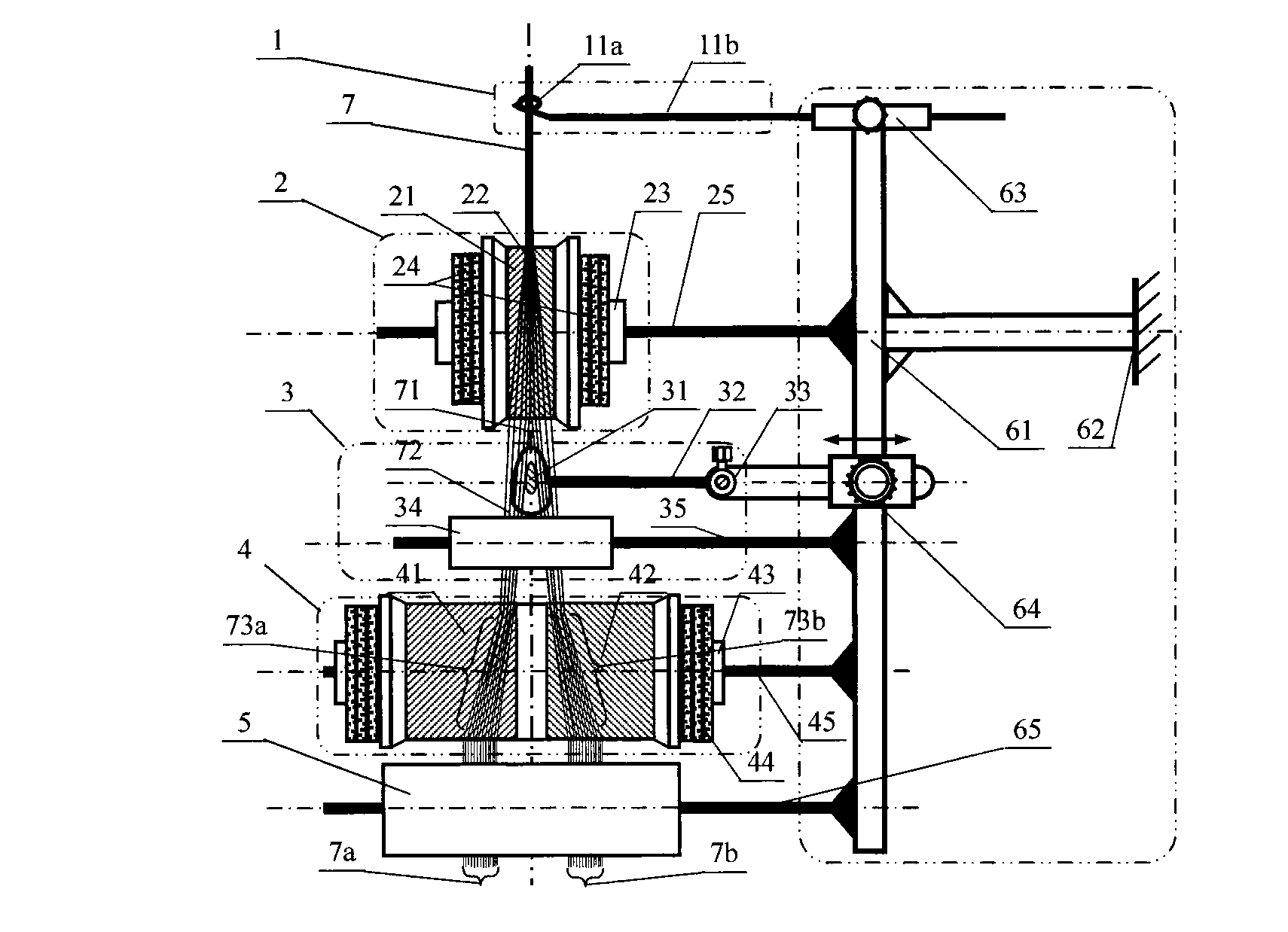

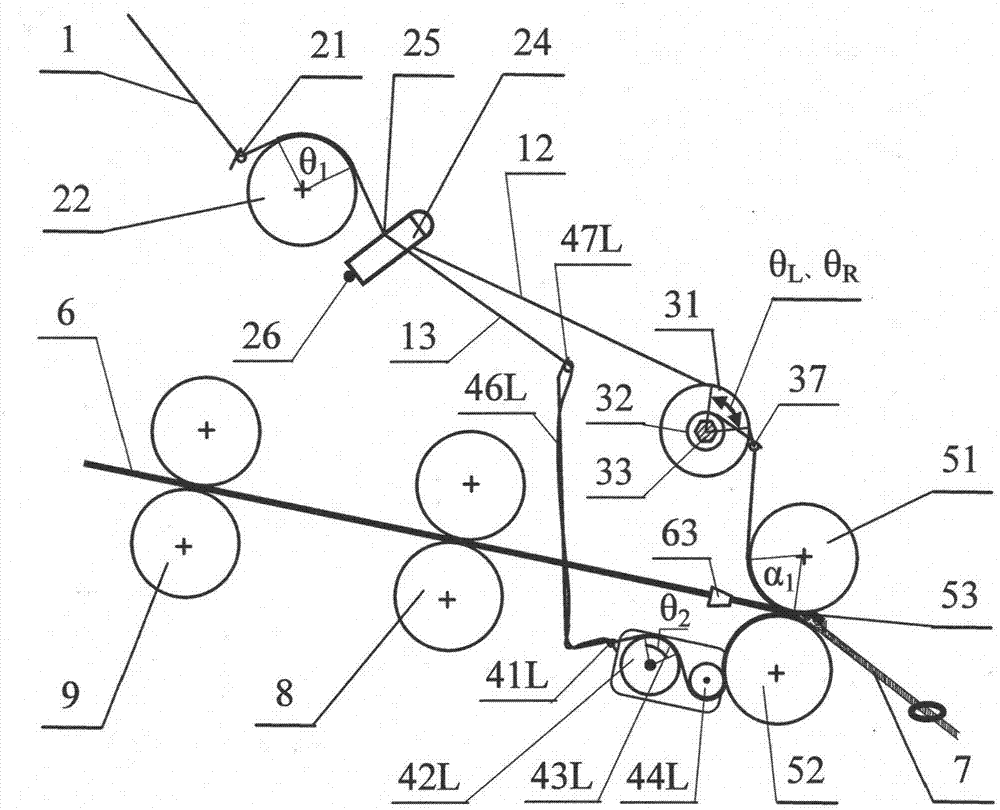

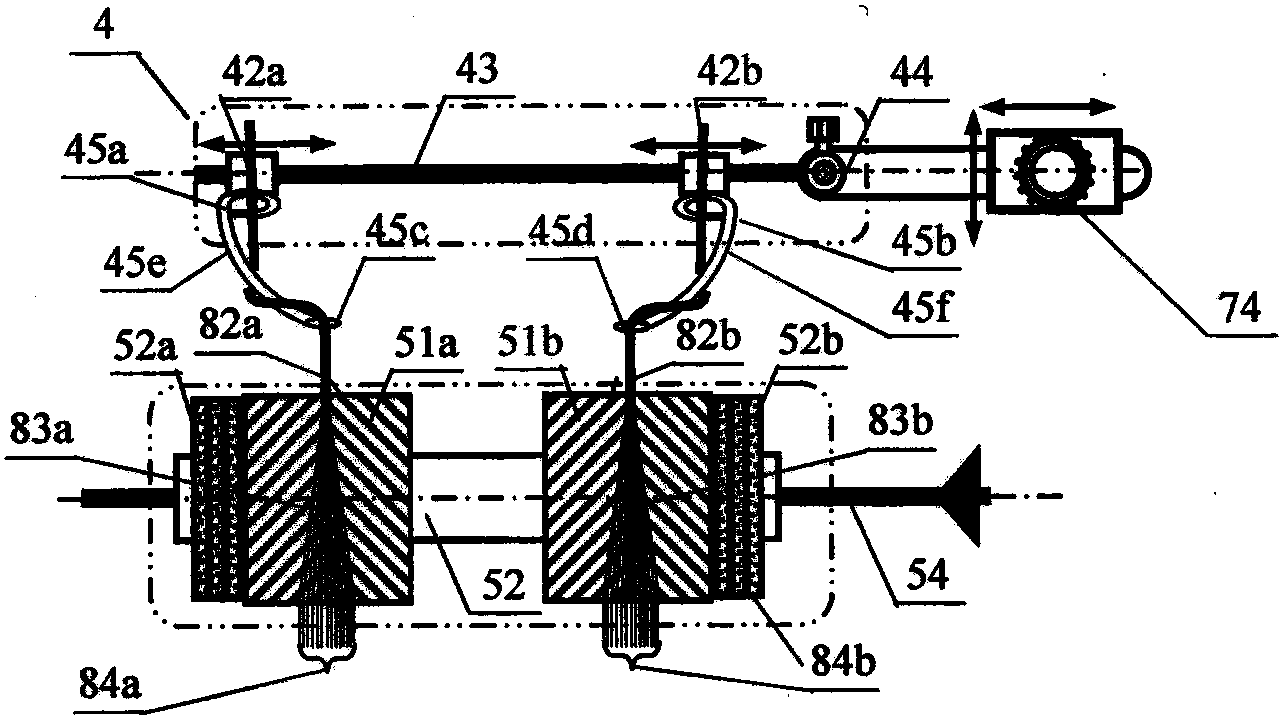

Filament beam splitting two-axis unfolding device and application

The invention relates to a filament beam splitting two-axis unfolding device and application thereof. The unfolding device comprises a central snail wire, a flattening roller set, a splitting rod, a pair of snail wires which are used for guiding a two-axis filament, a pair of unfolding rollers and a driving roller, and the unfolding device is connected to a fixation support and is arranged on a ring spinning frame by virtue of the fixation support. A method for realizing filament beam splitting two-axis unfolding is characterized in that a filament is located on a central line of the flattening roller set by virtue of the central snail wire, a tow is unfolded by virtue of the flattening roller set; then the tow is symmetrically split into two tows by virtue of the splitting rod, the two tows are fed by virtue of the snail wires in a way of aligning the central line of each screw thread in an'inverted V' shape, the two tows are unfolded into a silk screen by virtue of the unfolding rollers; and the silk screen is output around the driving roller appressed to a front roller. The unfolding device can be applied to spinning of super-short, easy-flaky and easy-flying fibers, shorter and weak recycling fibers and protective, soft, smooth, high count and superlow count composite yarn.

Owner:DONGHUA UNIV

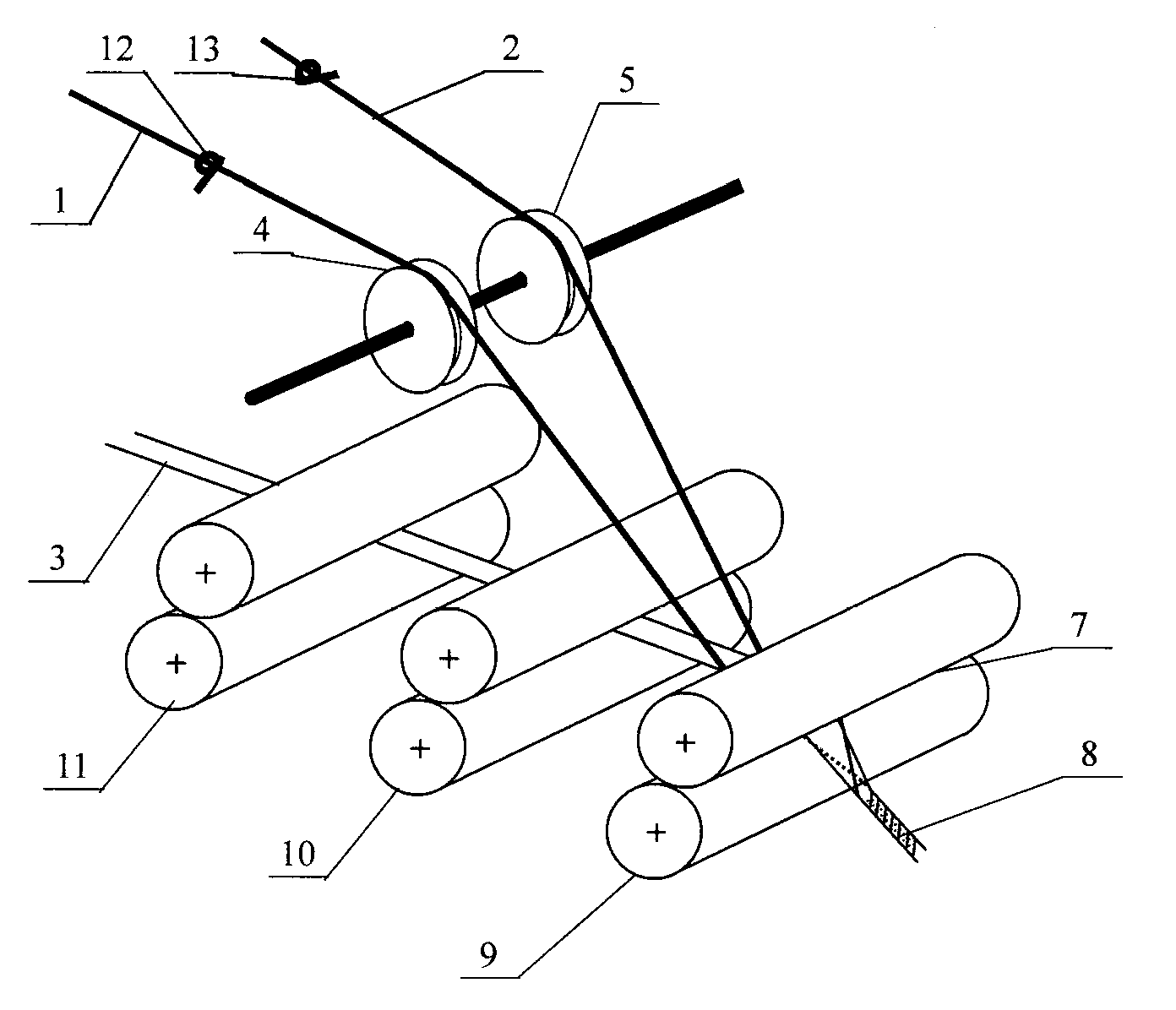

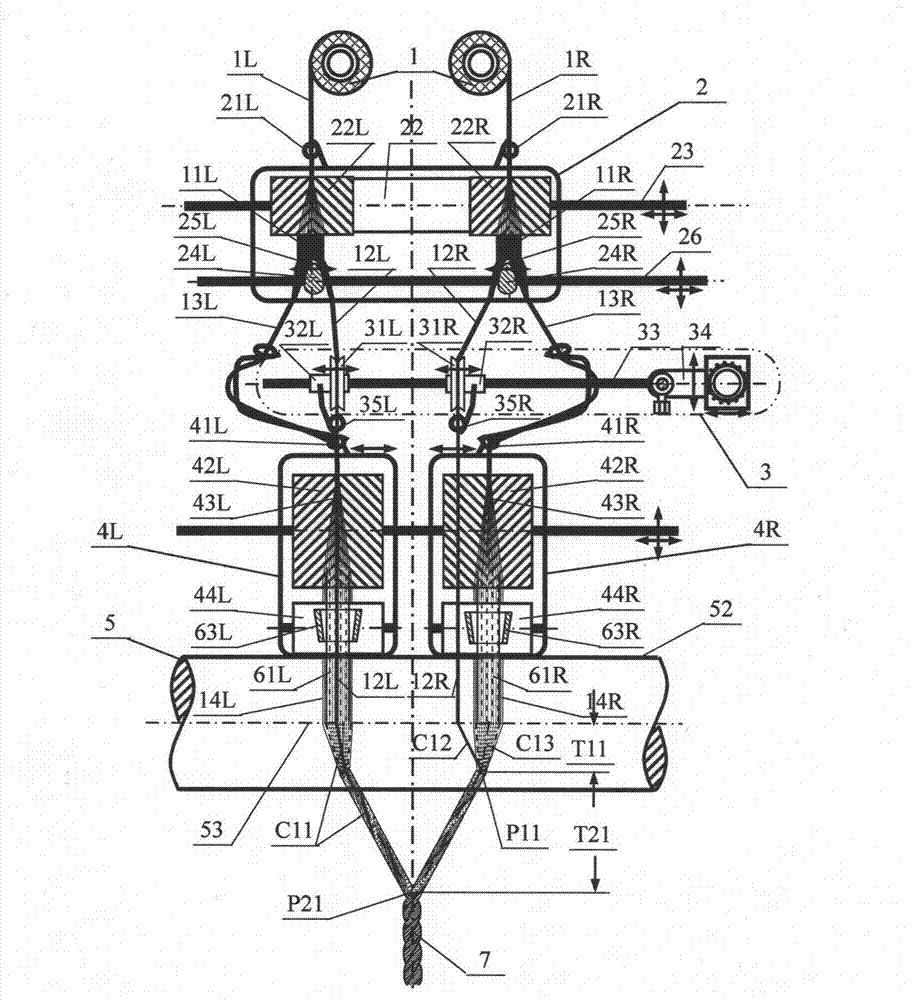

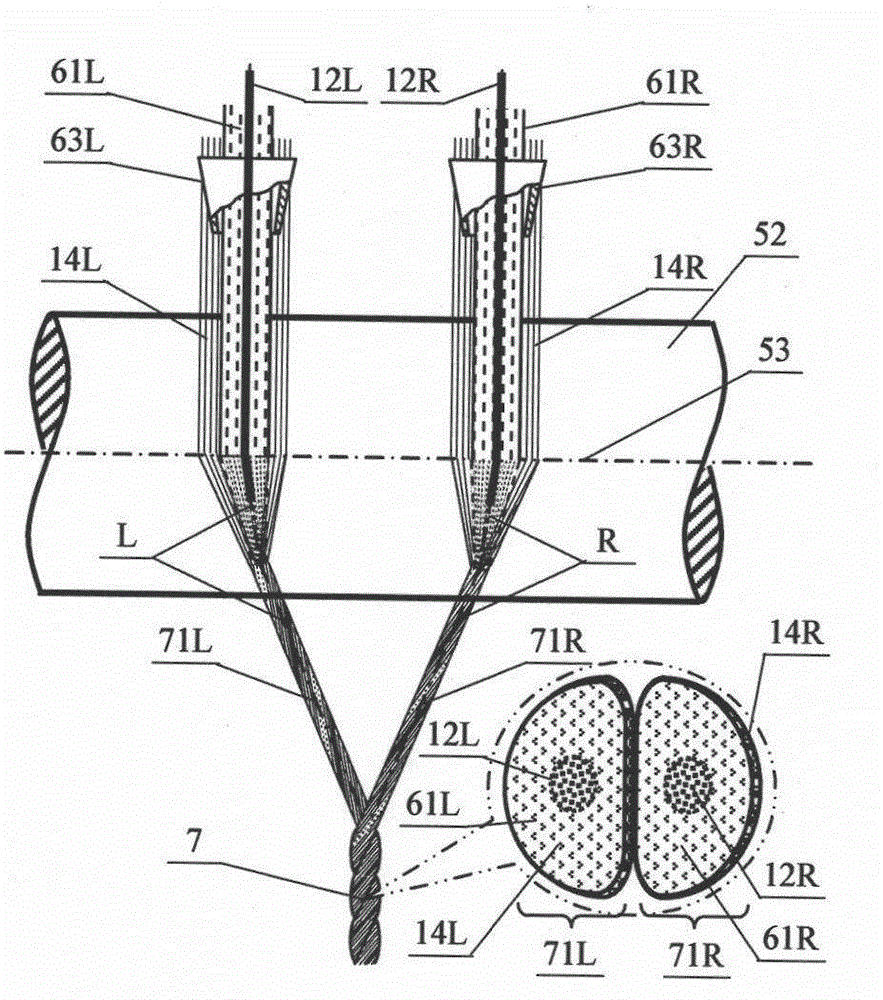

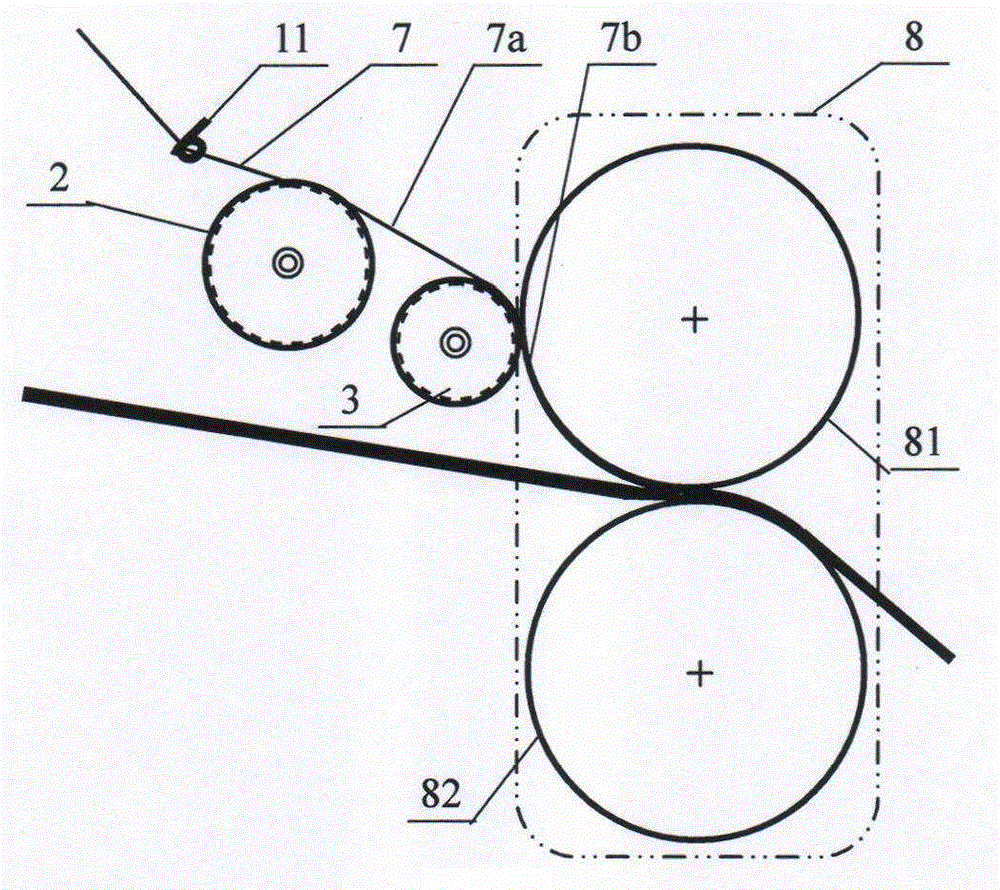

Three-shafting composite spinning method of constant-tension double-filament adjoining and twisting triangular zone and application thereof

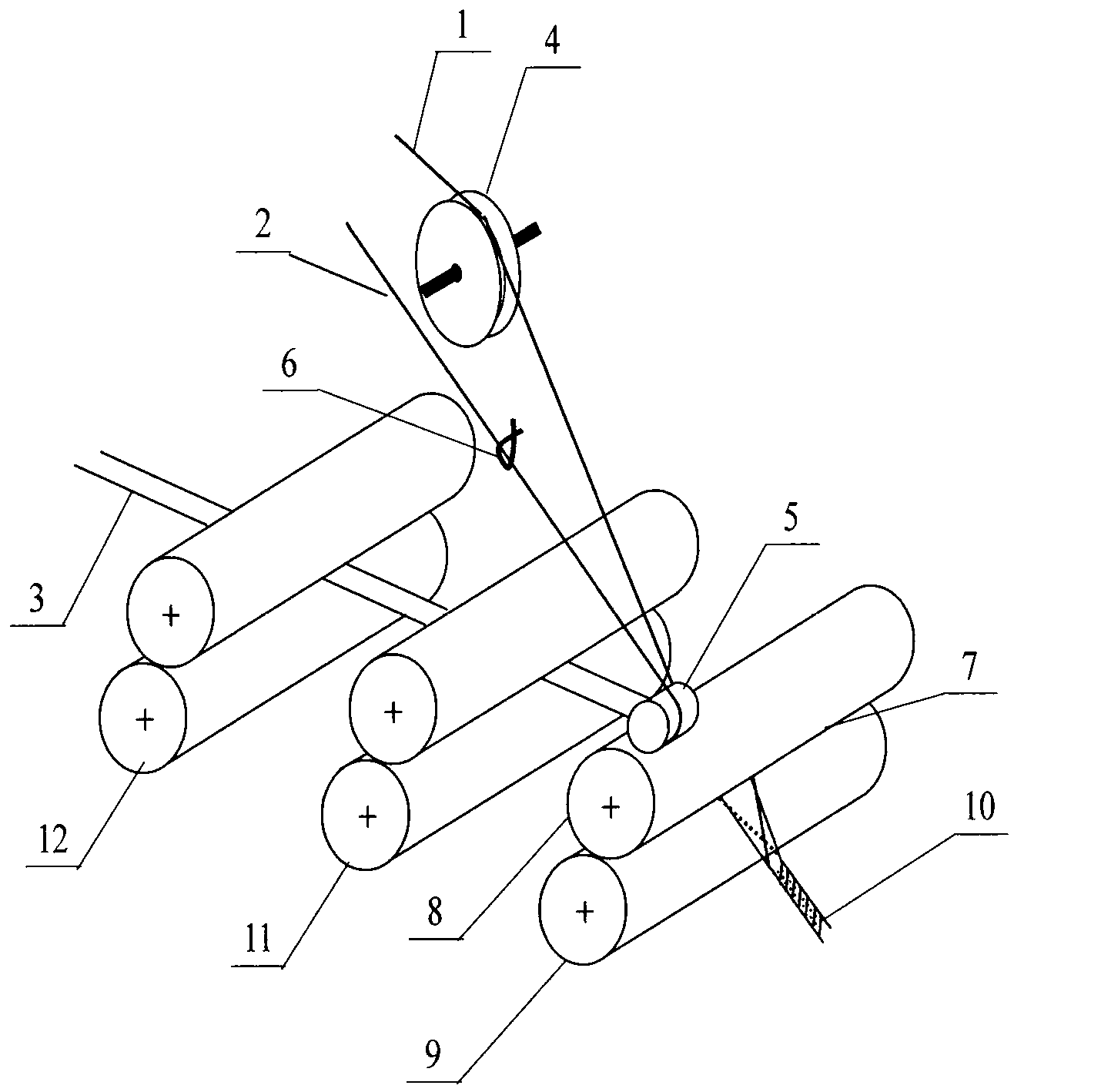

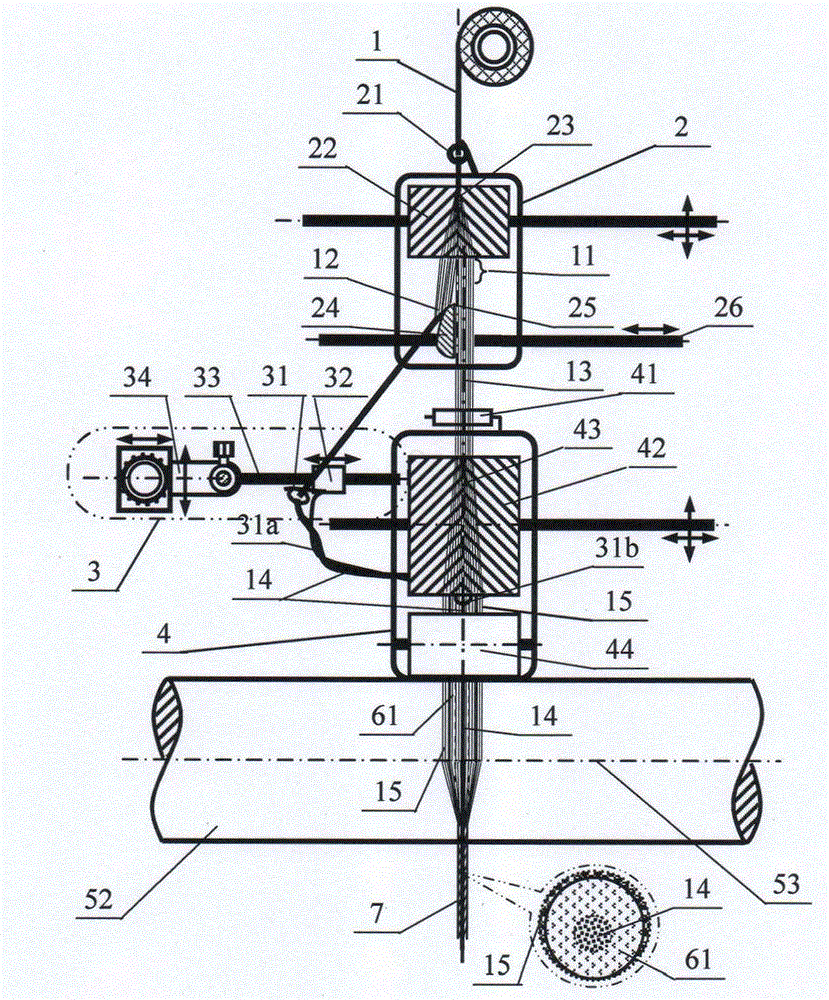

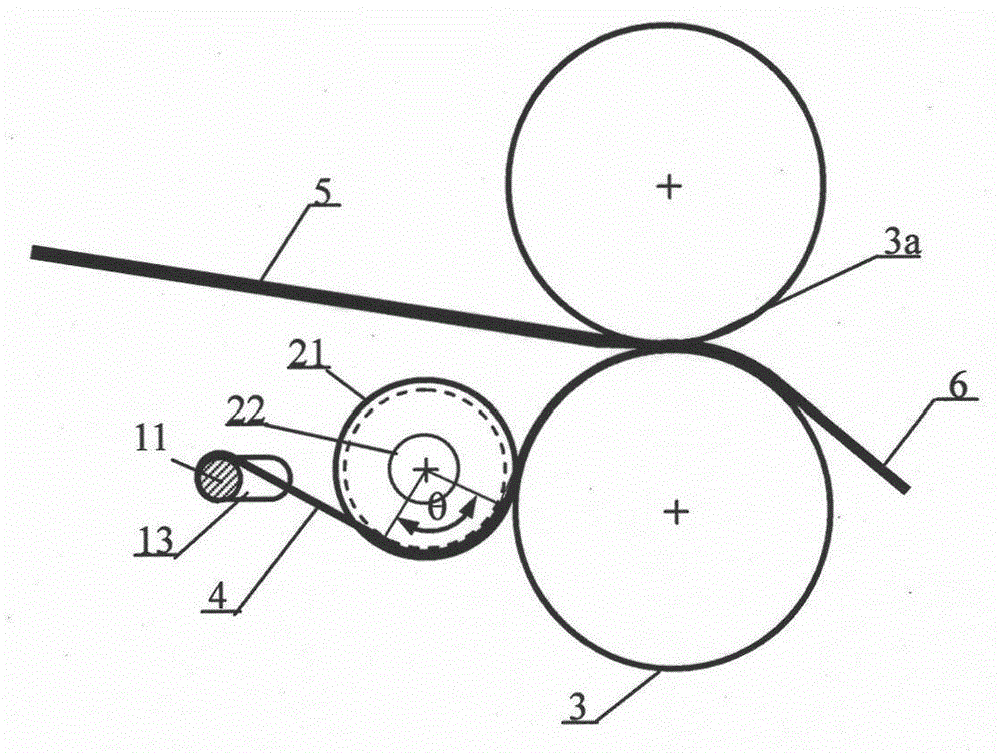

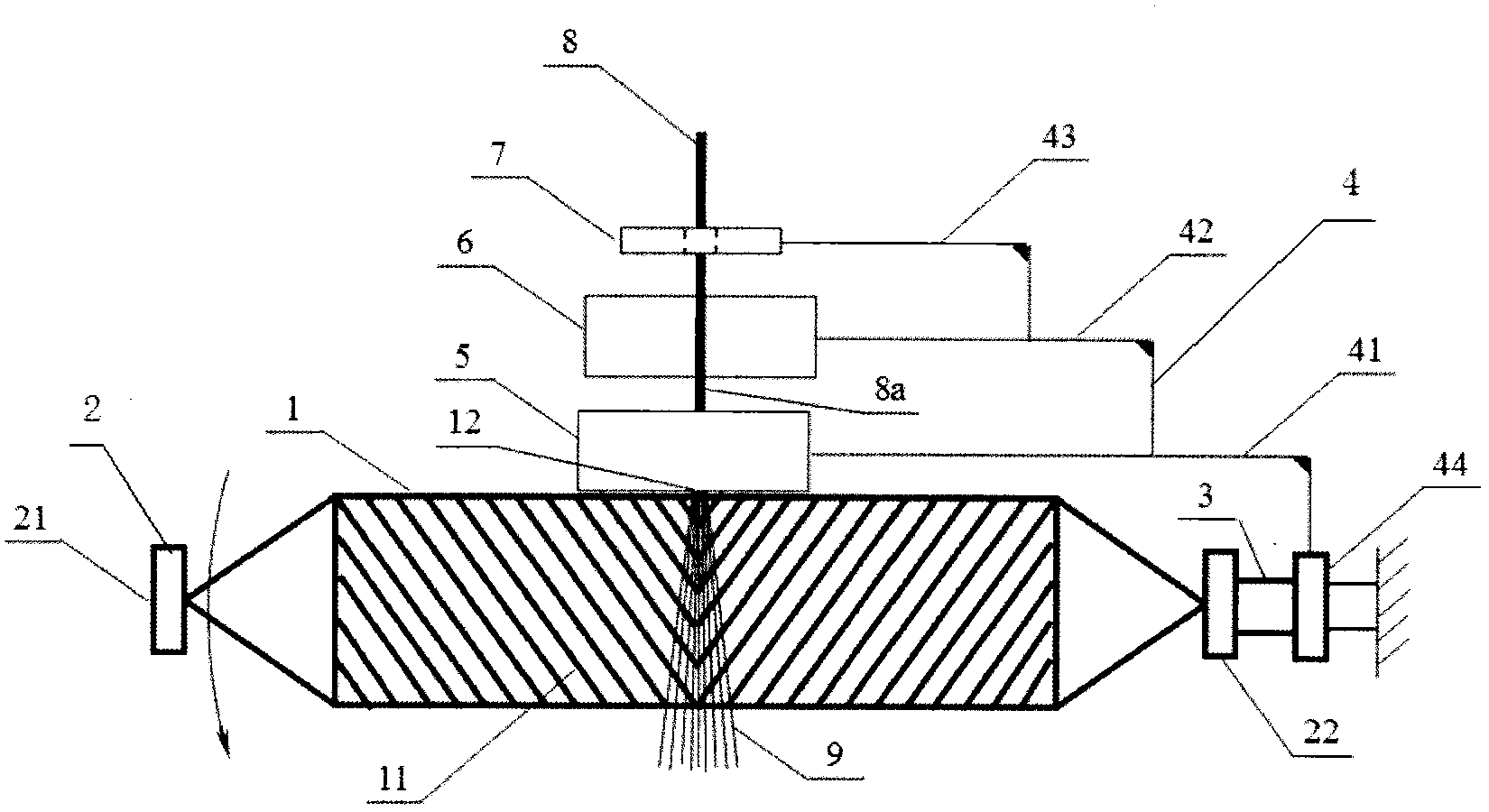

InactiveCN102704124BAdjustable positionHigh glossDrafting machinesContinuous wound-up machinesWhiskersConcentrator

The invention relates to a three-shafting composite spinning process of a constant-tension double-filament adjoining and twisting triangular zone and application thereof. The process comprises the steps of adopting a double-tension wheel to enable two beams of filaments to synchronize with the three-shafting in a way of adjoining left and right sides of a short fiber whisker strip via constant tension to be fed into a front roller through a beam concentrator; after outputting from a jaw of the front roller, wrapping the two beams of the filaments on the short fiber whisker strip in the twisting triangular zone to form a smooth composite yarn with the short fiber whisker strip wrapped by the double filaments basically in a no self-twisting manner. The process is simple and practical, can efficiently improve spinning efficiency and high branching of fibers with worse spinnability and reduce flying, scraps and fluffs in the spinning process, and is suitable for composite spinning of high-count smooth yarns and superfine yarns of shorter, weaker and ultra-short fibers.

Owner:DONGHUA UNIV

Non-equal beam-splitting composite yarn with different beams, spinning method and application

The invention relates to a nonequivalent beam splitting different-shaft-beam-net composite yarn, a spinning method and application. The composite yarn is a close net-wrapped yarn, a close net-wound yarn, a dislocated net-wrapped beam coating yarn and a beam-net coating and winding yarn formed by three-axis system composite spinning of tows and silk screens with nonequivalent filament numbers and staple fiber bars; and the composite yarn can be used for weaving textiles and high-grade fabrics with clear grains, flexibility, wear resistance, high strength, fuzzing and pilling resistance, attractiveness and comfortableness. According to the spinning method for the composite yarn, endless tows are unfolded to form a filament layer which is spit into two silk layers with nonequivalent numbers by adopting a filament unfolding and spitting device; one silk layer straightly travels or is downwardly led to be unfolded by a filament unfolding device to form a silk screen from top to bottom or is separated; and the other silk layer downwards travels or upwards travels to enable a bundle to be tightly close or separated, is synchronously fed with the stable fiber bars and is twisted to from a beam net composite yarn with a wrapping structure. The spinning method is suitable for spinning protective, soft and smooth, high-count and superfine-count composite yarn formed by super-short fibers, fibers which easily fall scrip and easily fly as well as extremely-short and extremely-weak reclaimed fibers.

Owner:DONGHUA UNIV

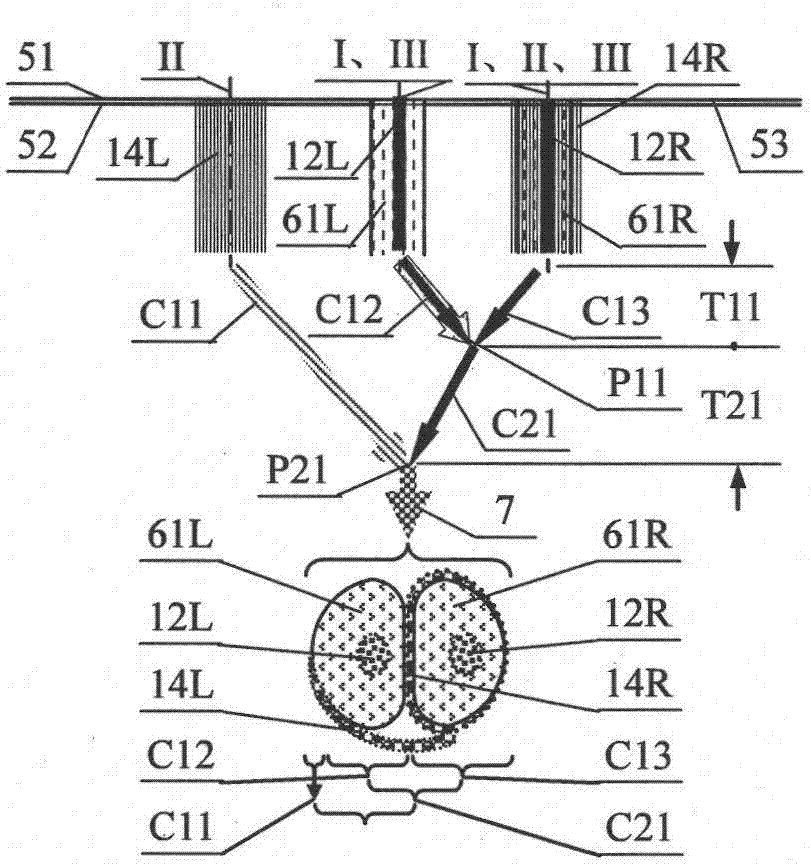

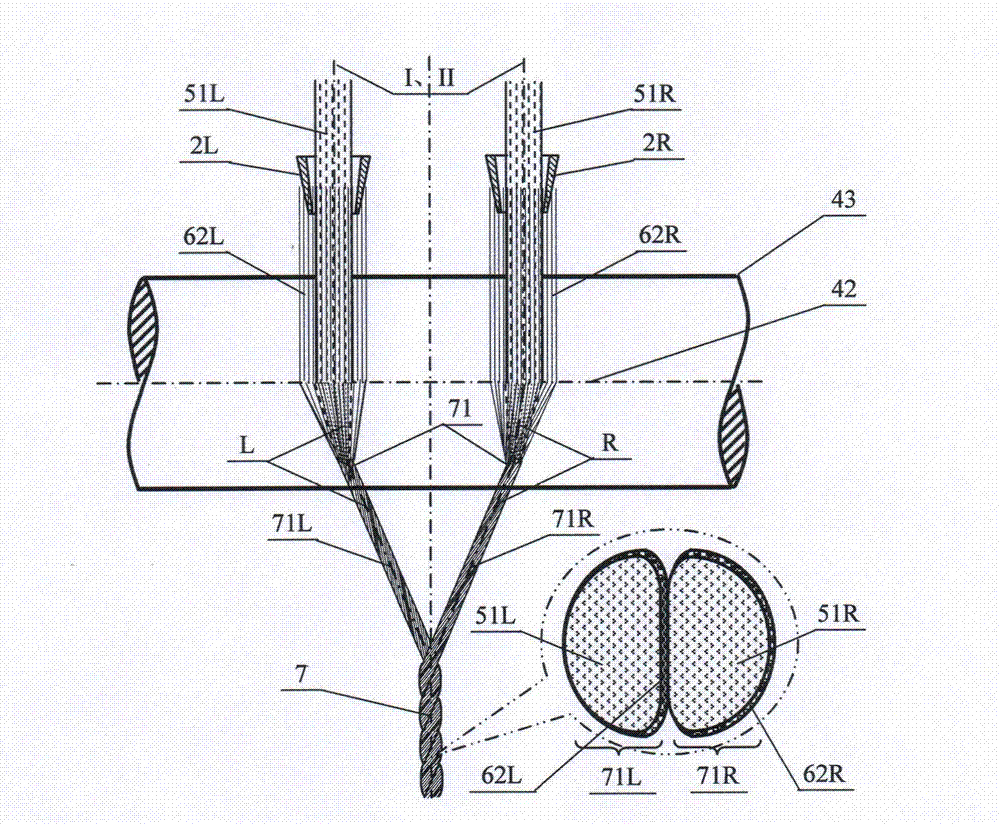

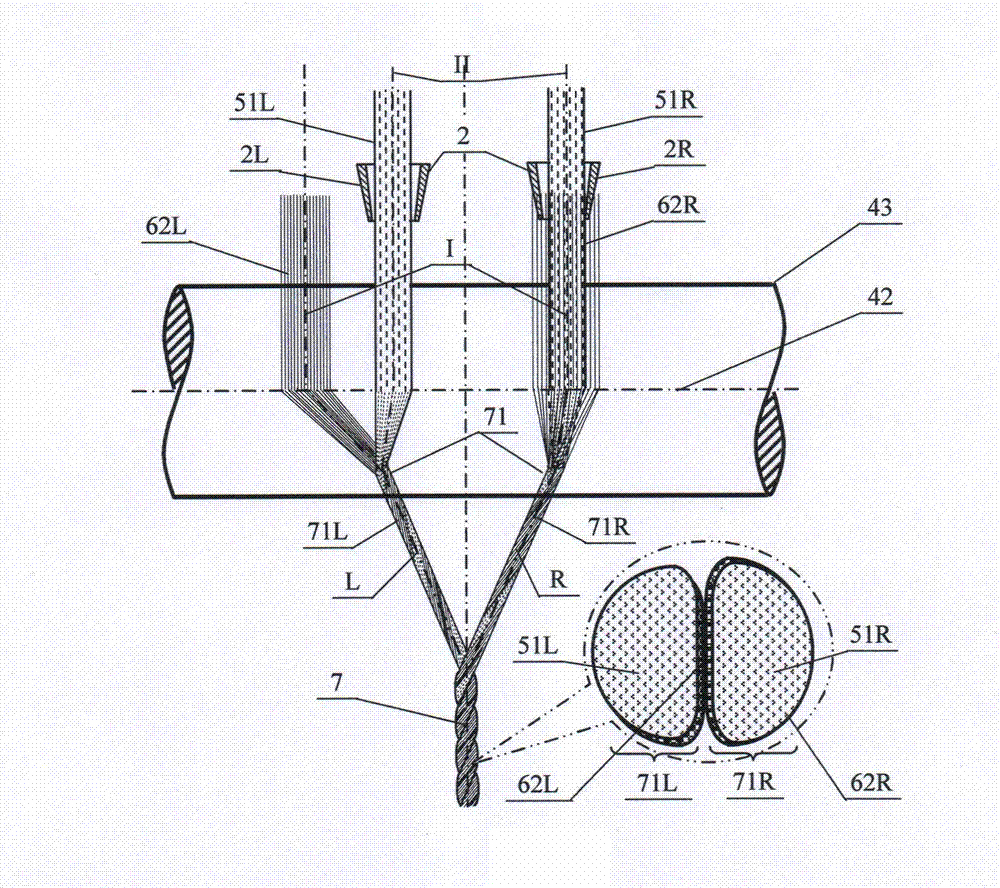

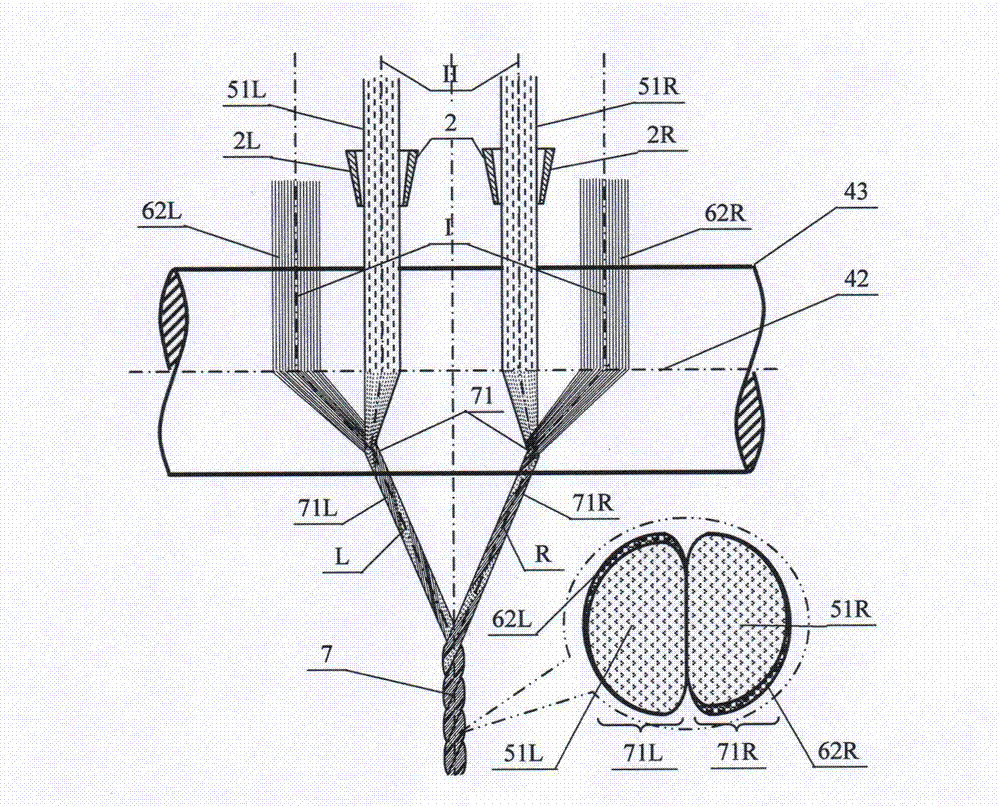

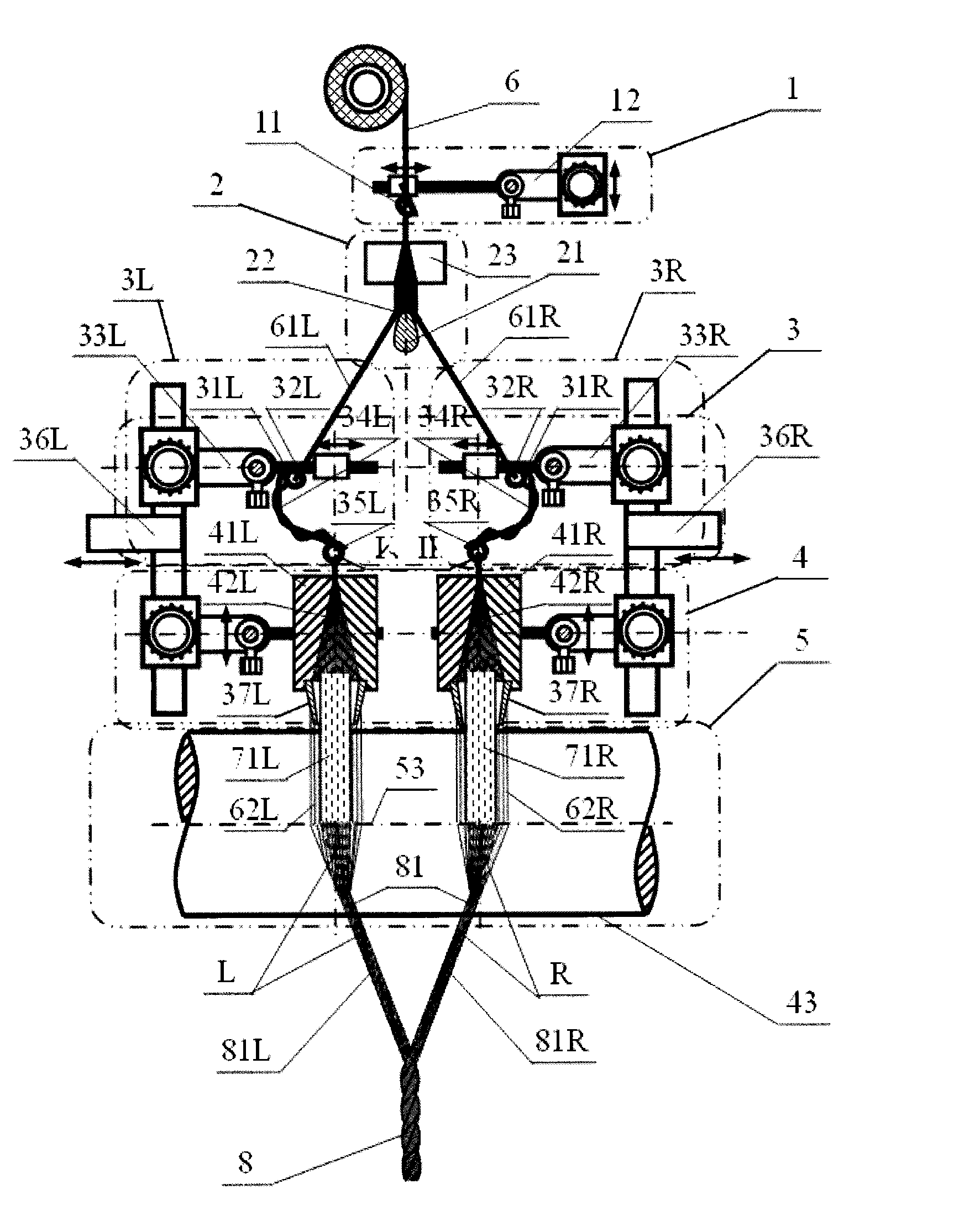

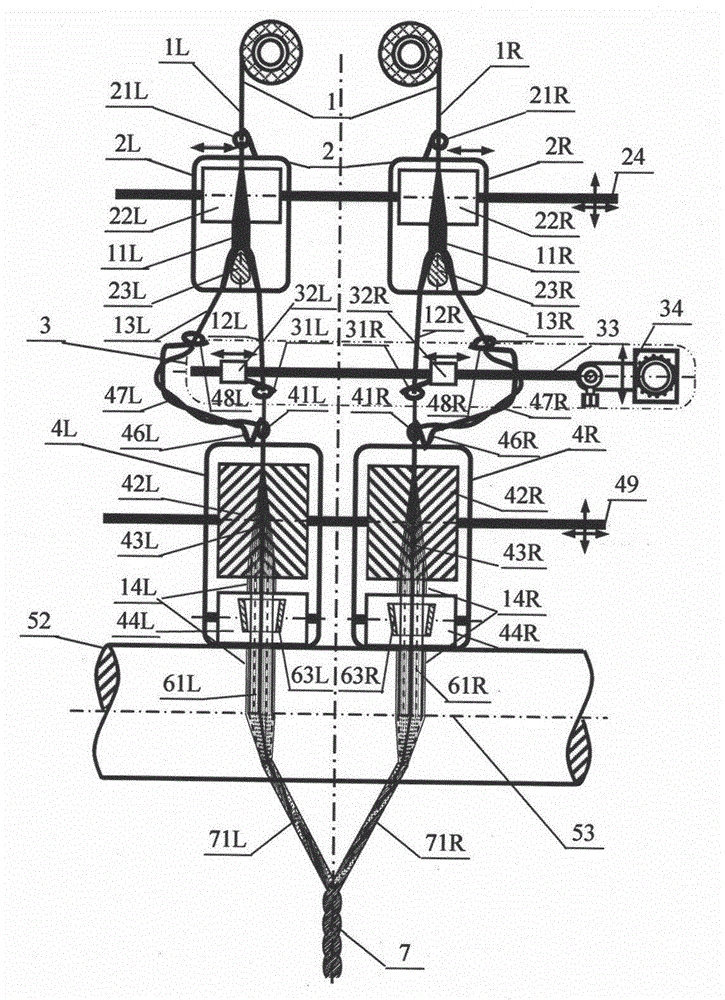

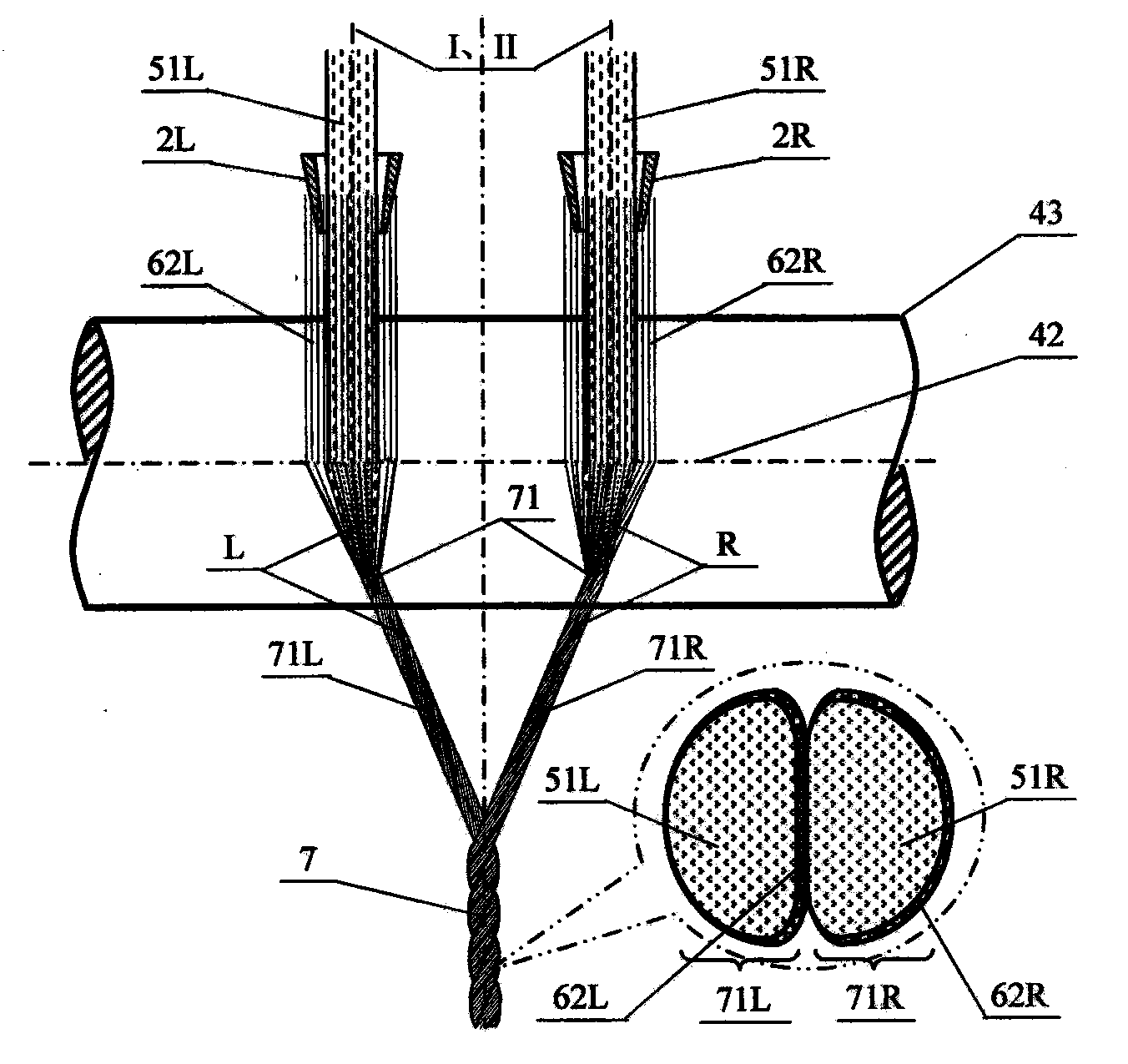

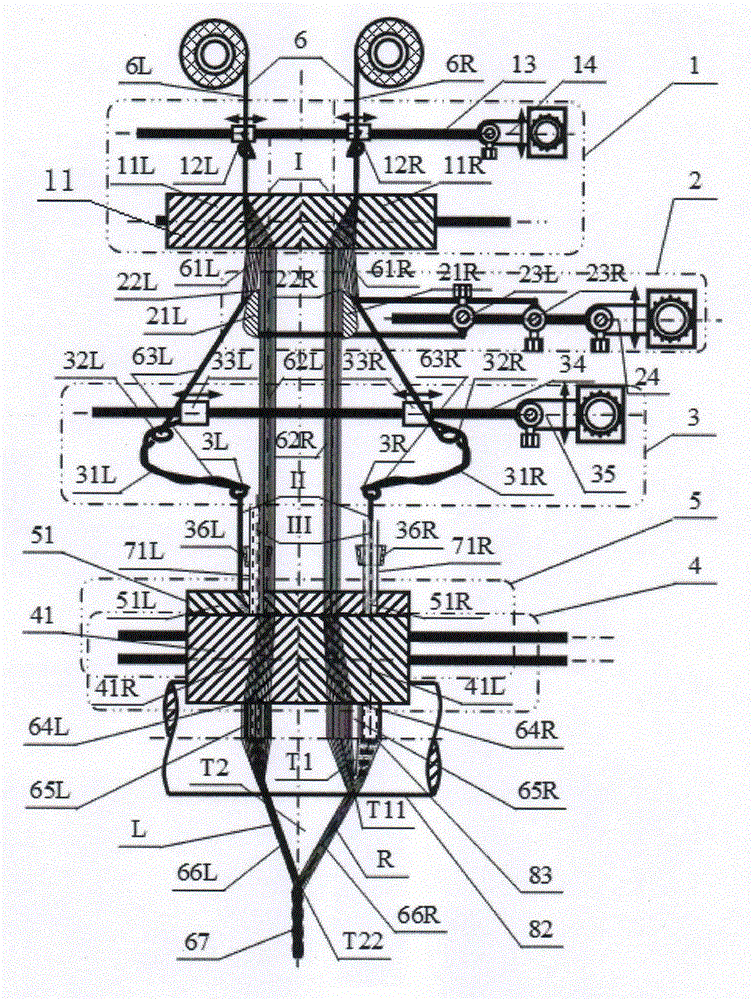

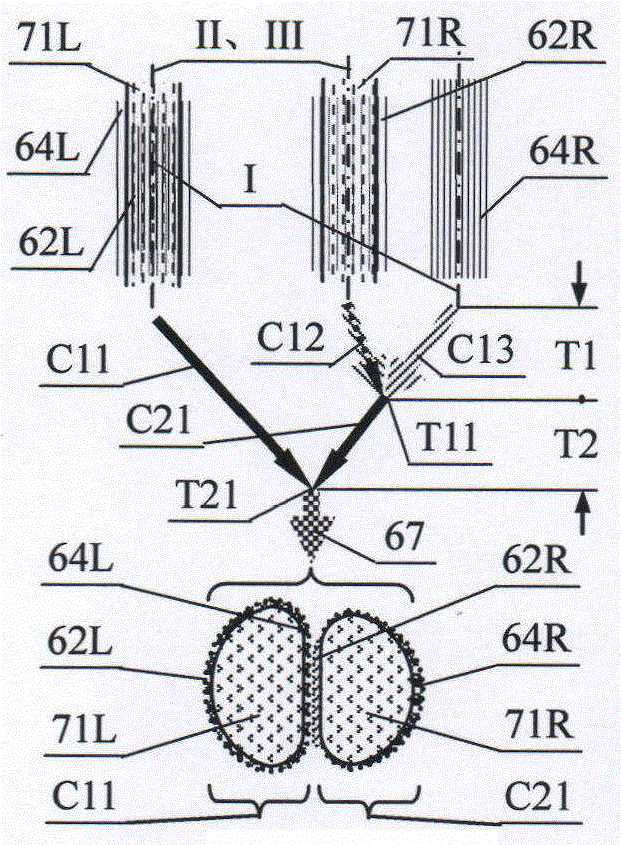

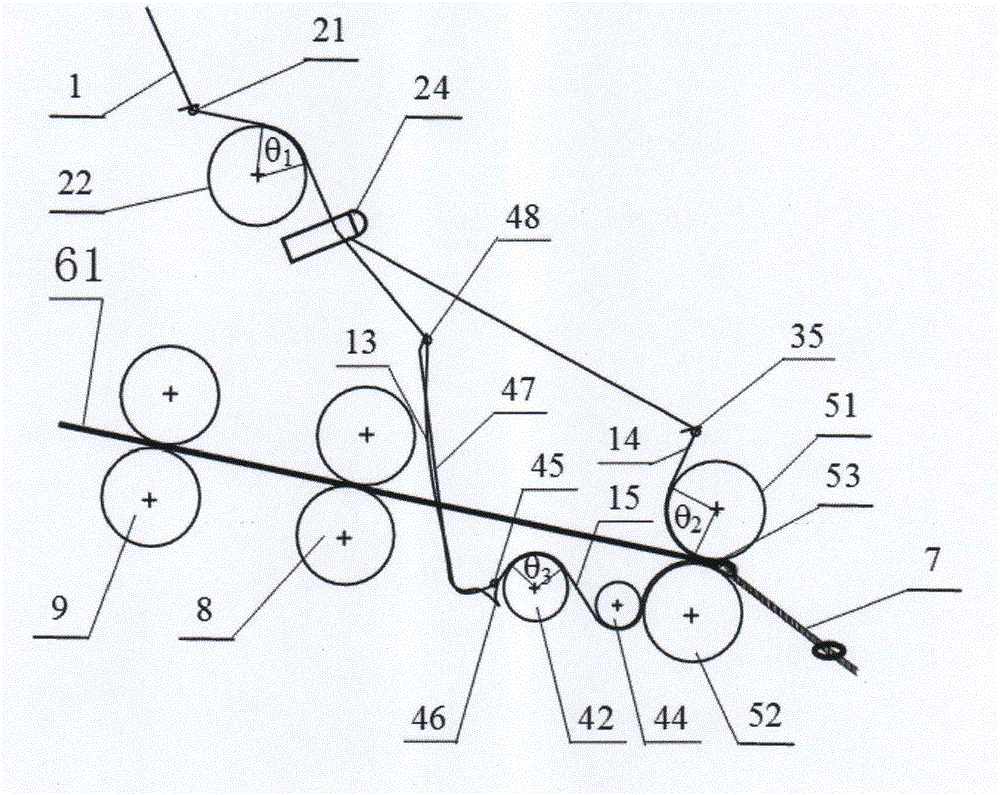

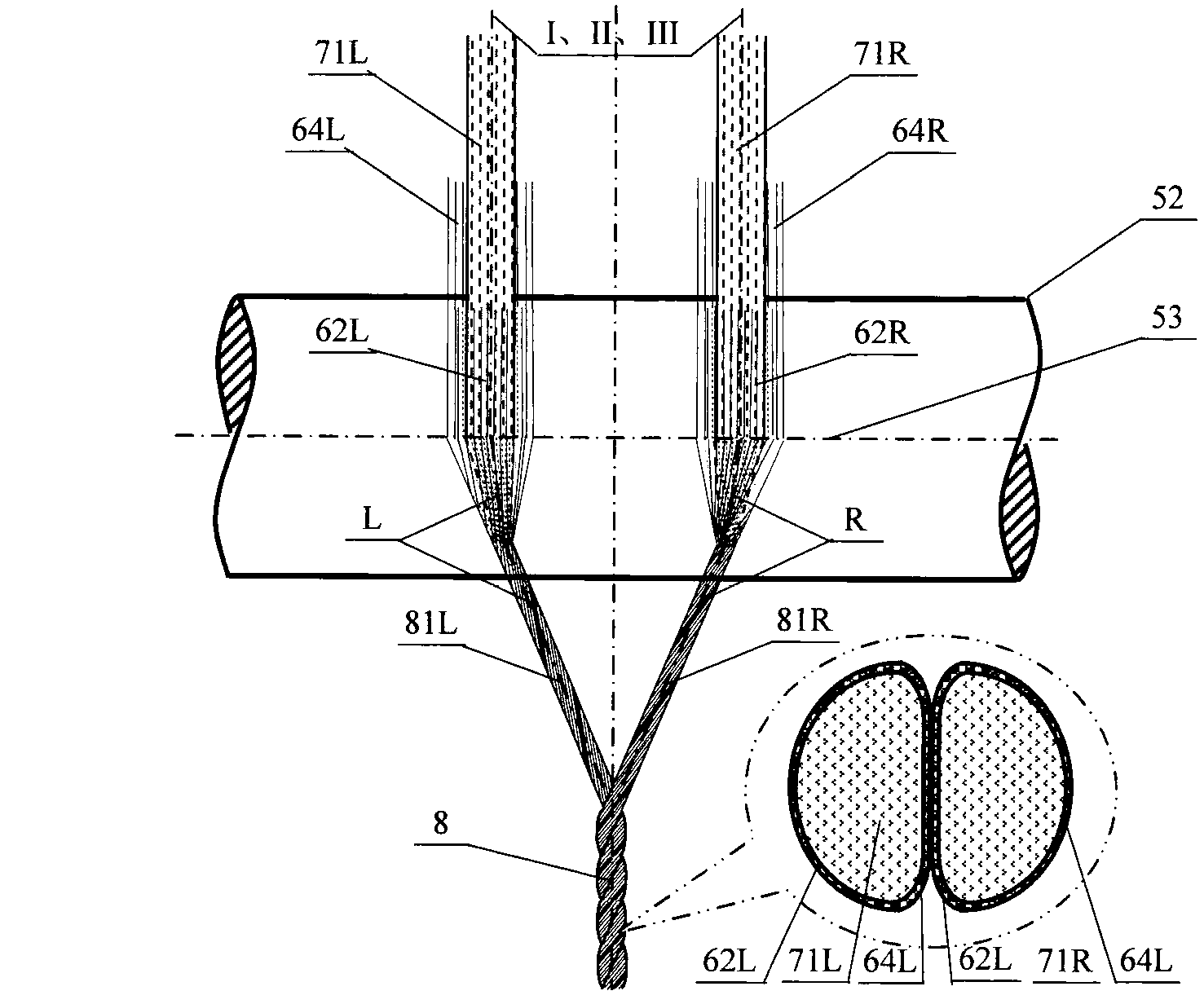

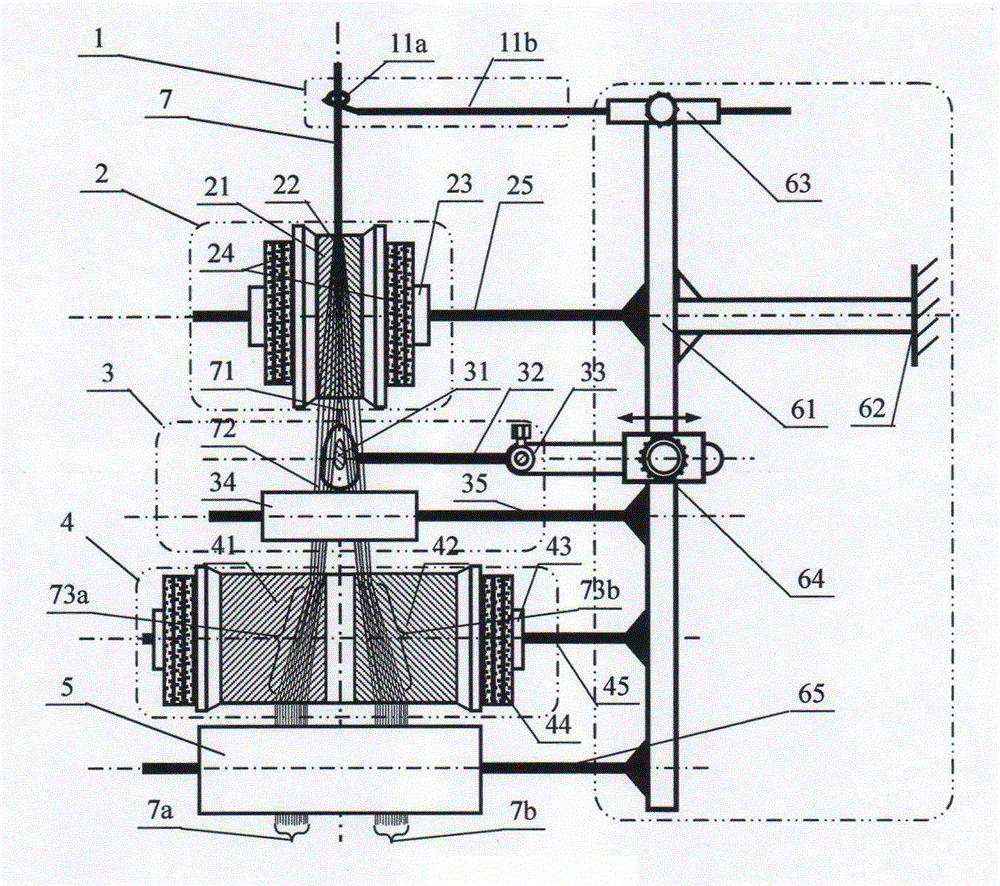

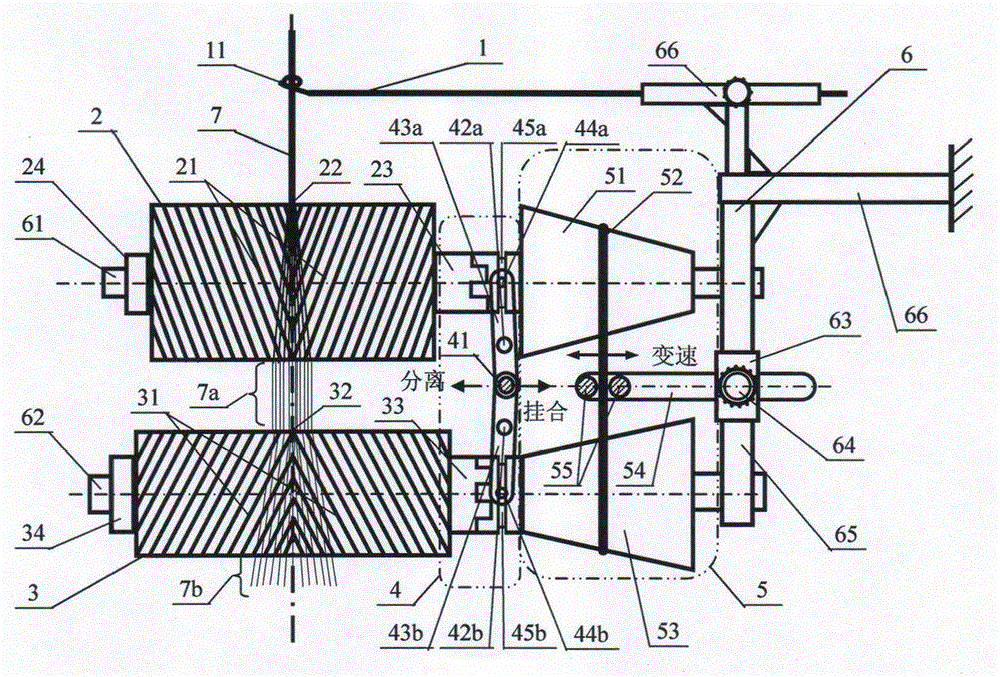

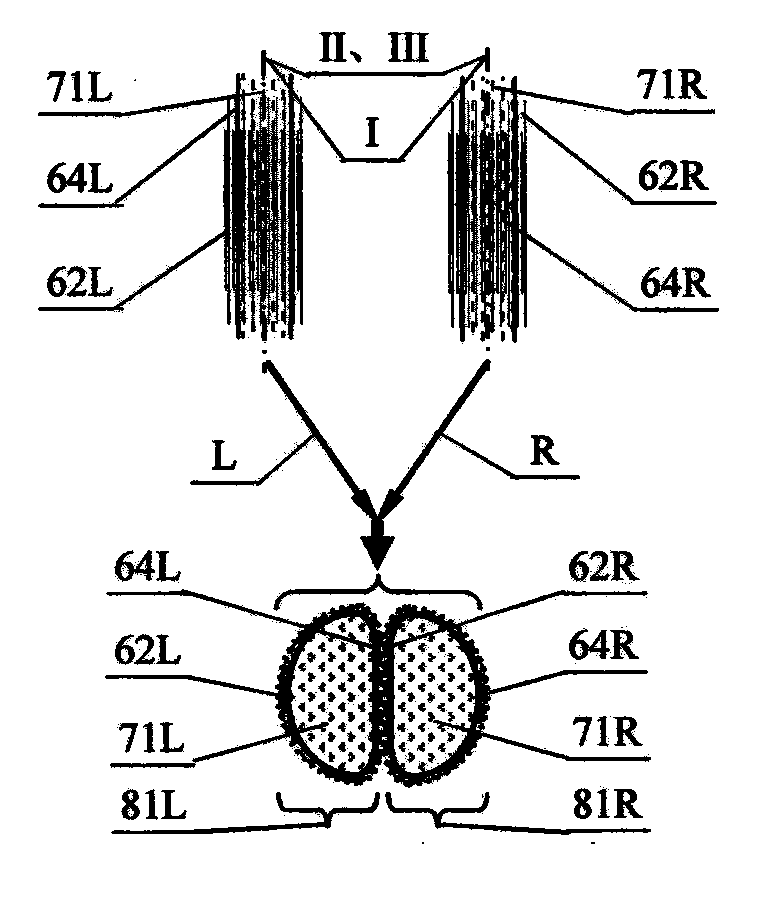

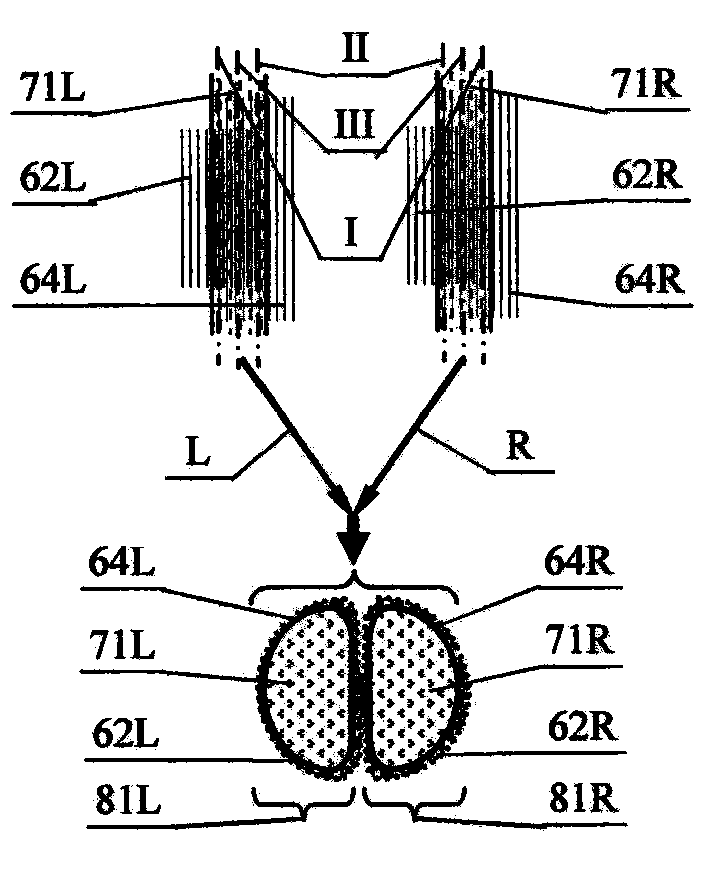

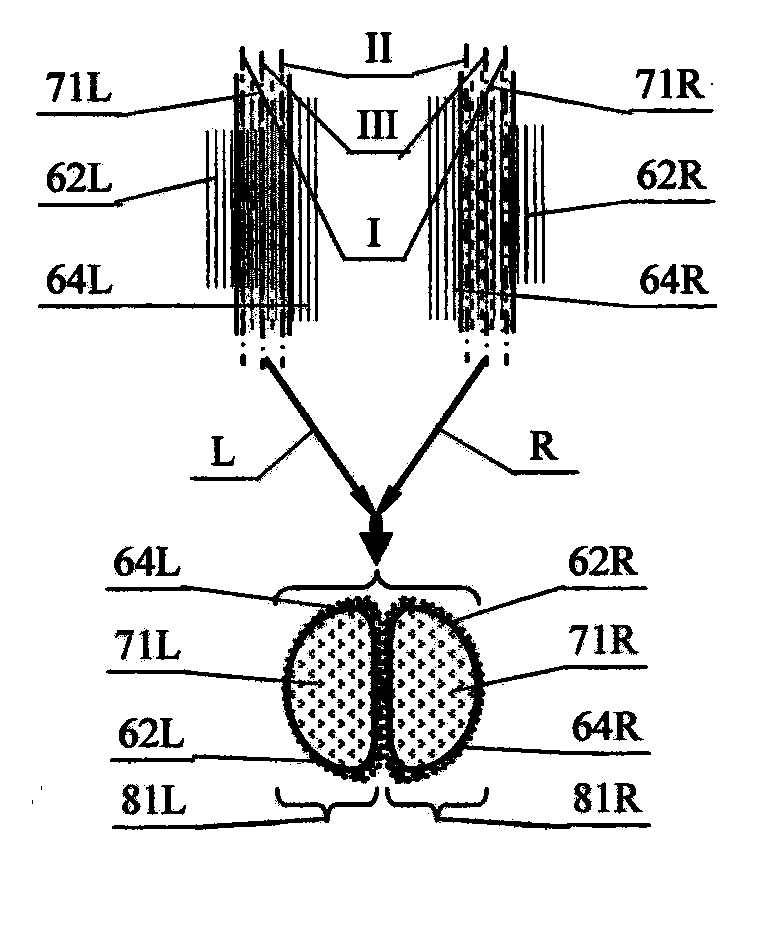

Two-bundle screen symmetrical composite yarn, spinning method and applications thereof

InactiveCN102704125BHigh spinnable countHigh breaking strengthContinuous wound-up machinesYarnFiberYarn

The invention relates to a two-bundle screen symmetrical composite yarn, a spinning method and applications thereof. The composite yarn is of 3*2 double-bundle screen composite yarn by conducting 3-shafting compounding to silk frock / chopped fiber / silk screen and 2-shafting symmetrical compounding, has three forms of composite yarns of two screen-wrapped core-spun yarns, two screen-wrapped abut yarns and two screen-wrapped fascinated yarns, and can be used for weaving fabric and fine high-grade fabric, which have clear textures, are soft and wear-resistant, high in strength and pilling-proof and attractive and comfortable. The spinning method for realizing the composite yarn comprises the following steps: two filaments are split into four bundles by a splitter, wherein two bundles are fed in by means of being centered, abutted, or left from chopped fiber strands; the other two bundles are spread by a filament spreader into silk screens, and are fed in by means of bottom supporting or top covering the chopped fiber strands, and the silk bundles and the silk screens are used for clamping chopped fiber strands to be wound into yarns, and then symmetrical twisting and compounding are conducted to form yarns. The method is applicable to spinning of protective type soft, smooth and high-count composite yarns for ultrashort fibers which are easy to fall crumbs and easy to fly, as well as shorter and weaker reclaimed fibers.

Owner:DONGHUA UNIV

Two-bundle screen symmetrical composite yarn, spinning method and applications thereof

The invention relates to a two-bundle screen symmetrical composite yarn, a spinning method and applications thereof. The composite yarn is of 3*2 double-bundle screen composite yarn by conducting 3-shafting compounding to silk frock / chopped fiber / silk screen and 2-shafting symmetrical compounding, has three forms of composite yarns of two screen-wrapped core-spun yarns, two screen-wrapped abut yarns and two screen-wrapped fascinated yarns, and can be used for weaving fabric and fine high-grade fabric, which have clear textures, are soft and wear-resistant, high in strength and pilling-proof and attractive and comfortable. The spinning method for realizing the composite yarn comprises the following steps: two filaments are split into four bundles by a splitter, wherein two bundles are fed in by means of being centered, abutted, or left from chopped fiber strands; the other two bundles are spread by a filament spreader into silk screens, and are fed in by means of bottom supporting or top covering the chopped fiber strands, and the silk bundles and the silk screens are used for clamping chopped fiber strands to be wound into yarns, and then symmetrical twisting and compounding are conducted to form yarns. The method is applicable to spinning of protective type soft, smooth and high-count composite yarns for ultrashort fibers which are easy to fall crumbs and easy to fly, as well as shorter and weaker reclaimed fibers.

Owner:DONGHUA UNIV

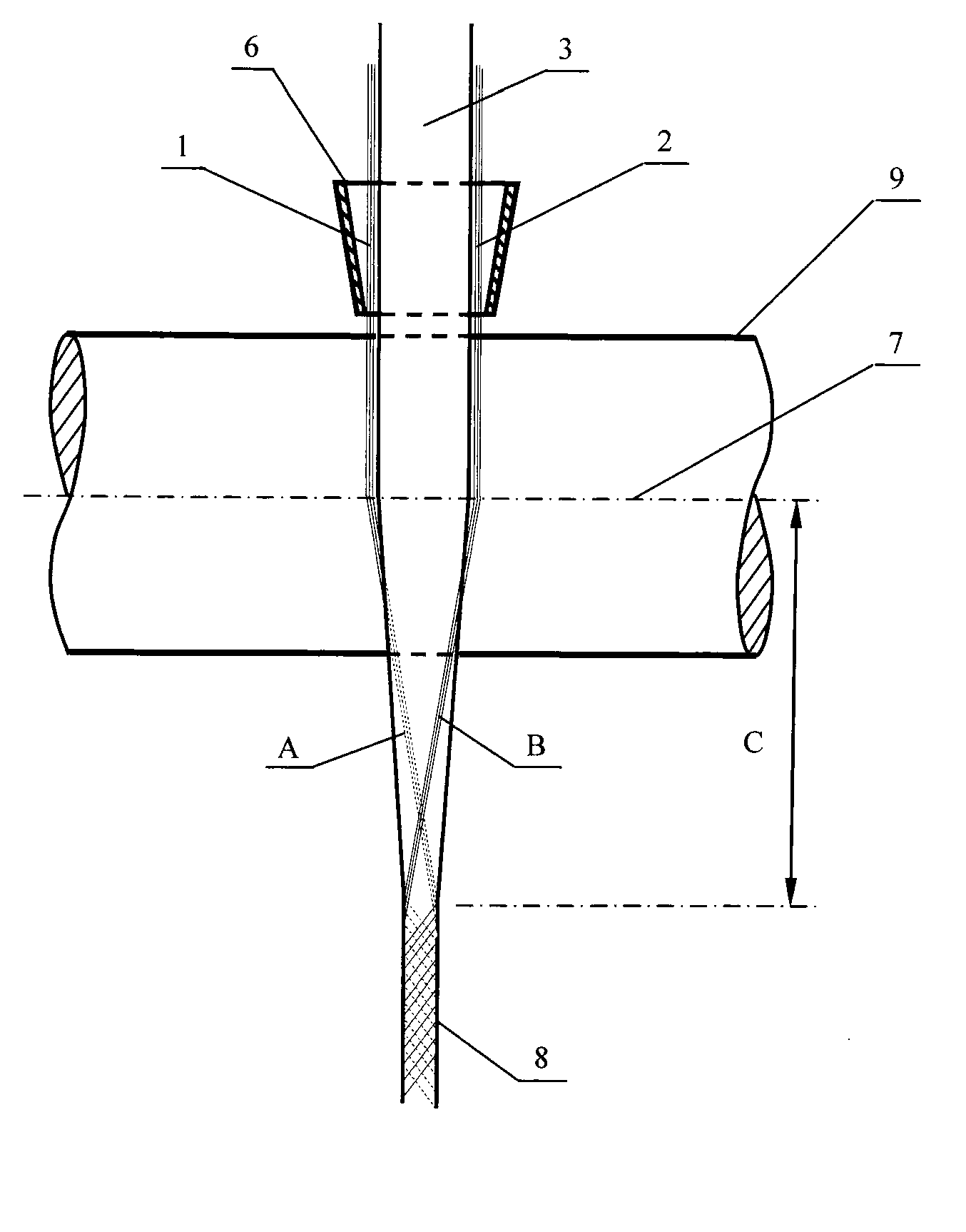

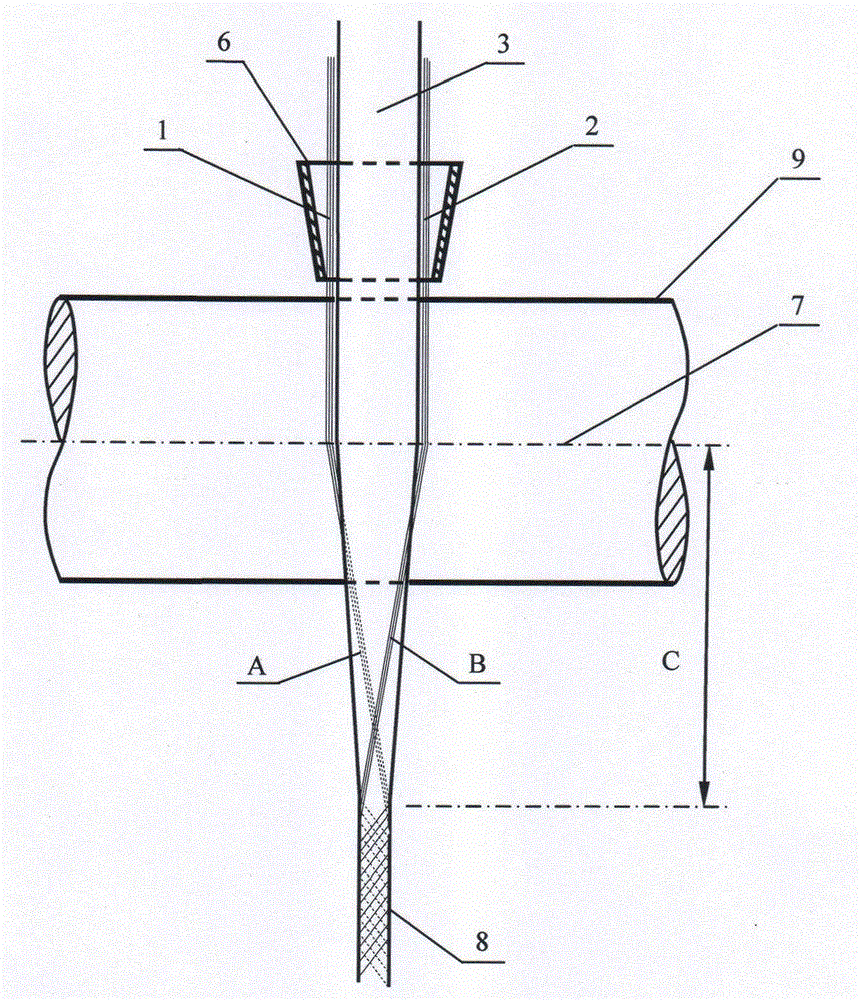

Lower support type cored enhanced three-axis composite yarn, spinning method and application

InactiveCN102704127BHighly branched forSuitable for ultra-high branch spinningContinuous wound-up machinesYarnEngineeringMiddle line

The invention relates to a lower support type cored enhanced three-axis composite yarn, a spinning method and application thereof. The composite yarn is of a three-layer structure and formed by enhancing through taking a bunch of long filaments as a core, cladding short fiber yarns and wrapping at the outmost layer through filament screen. The spinning method comprises the following steps of: feeding a bunch of long filaments into a lower support type yarn spreader so as to uniformly spread the long filaments into a lower support filament screen of which the width is more than or equal to that of the short fiber yarns; feeding another bunch of long filaments from upper part along the middle line of the short fiber yarns; feeding the short fiber yarns into a front roller jaw between a lower support filament screen and upper fed filament bunches, and forming core-enhanced, filament-screen-wrapped three-axis composite spun yarns under the twisting effect. The method provided by the invention is suitable for spinning protectively-enhanced, soft, smooth and high-count composite yarns from ultrashort, easily-flaky and easily-flying fibers and shorter and weaker recycled fibers. The yarns can be used for weaving into textiles and high-grade fine fabrics with clear texture, good luster, stable structure, abrasion resistance, high strength, anti-fluffing anti-pilling property and capability of preventing dropping chips.

Owner:DONGHUA UNIV

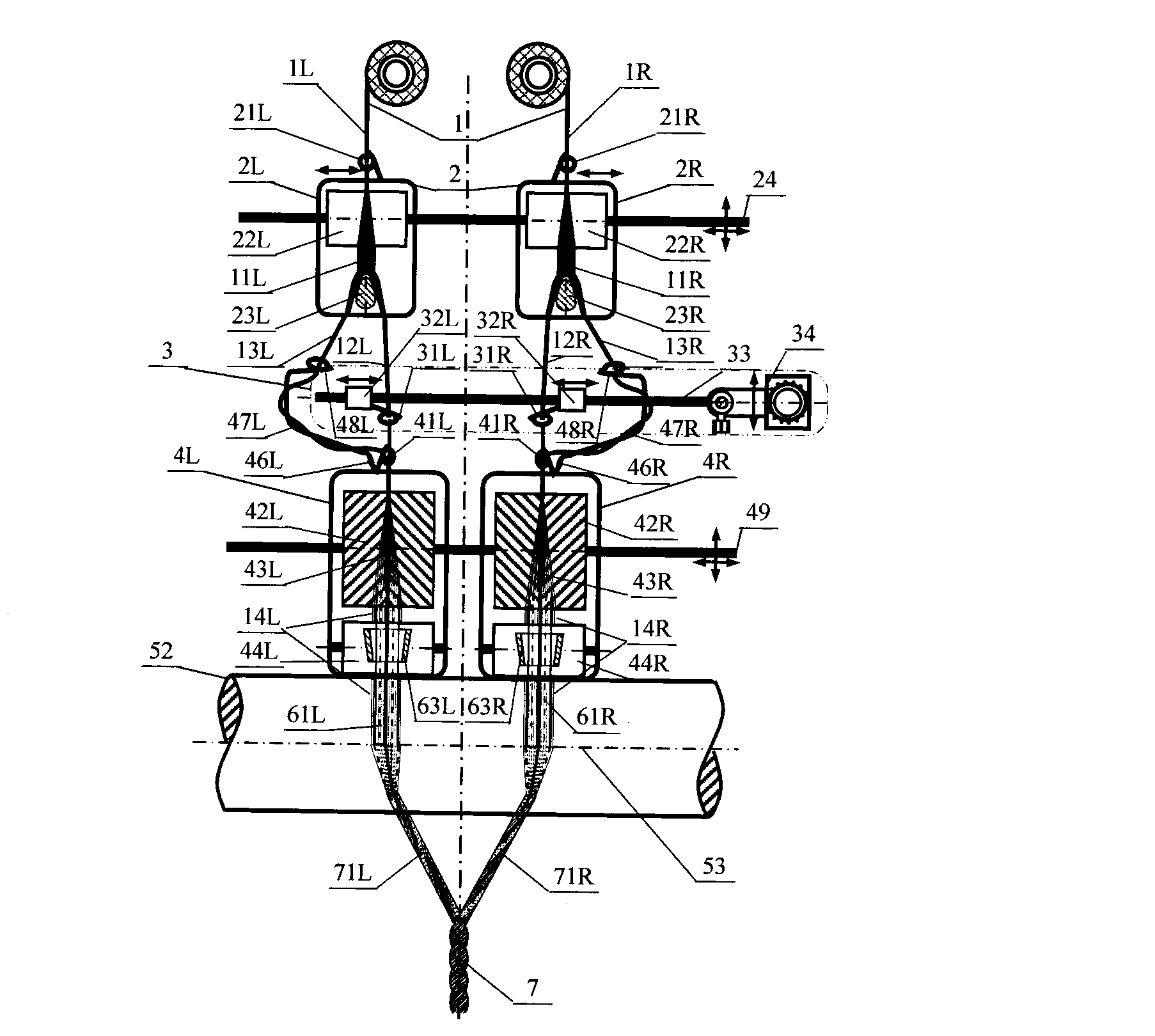

Silk net covering type 2*2 axis composite yarn, spinning method and application

The invention relates to a silk net t covering type 2*2 axis composite yarn, a spinning method and application. The composite yarn is 2*2 axis composite yarn which is formed by covering and compositing two short fiber whiskers on two silk nets respectively and comprises a net wrapping form, a net wrapping net covering form and a net covering form. The composite yarn in the net wrapping form, the net wrapping net covering form and the net covering form can be woven into textiles which are clear in texture, soft and wear-resistant, high in intensity, and attractive in appearance and comfortable and resist fluffing and pilling and high-grade fine fabric. According to the spinning method for the composite yarn, twizzles, bunchers and filament spreading devices are arranged on a ring spinning machine, two bundles of filaments are centered by a left twizzle and a right twizzle, then enter the respective filament spreading devices and are spread so as to form two covering silk nets; the two covering silk nets and the short fiber whiskers which are positioned by the bunchers enter a front roller jaw synchronously in upper and lower layers, the respective short fiber whiskers are wrapped and wound at a twisting triangular area, and the respective short fiber whiskers and the filaments are composited to form the composite yarn. The method is suitable for spinning soft, smooth and clean, high-count protective composite yarn of ultrashort fibers with high scrap falling and flying possibility and weak reclaimed fibers.

Owner:DONGHUA UNIV

Unequal rendezvous point spinning method of asymmetrical beam splitting spread filament, composite yarn and application

InactiveCN102704114BReduce dosageHigh breaking strengthDrafting machinesYarnNon symmetricBeam splitting

Owner:DONGHUA UNIV

Non-equal convergent point double tow-screen composite yarn, spinning method and application

Owner:DONGHUA UNIV

Upper covering type splitting yarn spreader for yarns, method and application

InactiveCN102704132BRealize cover-type protectionClear textureYarnPulp and paper industryFilament yarn

The invention relates to an upper covering type splitting yarn spreader for yarns. The yarn spreader is characterized by comprising a splitting roller, wherein the left end and the right end of the splitting roller are respectively provided with a thimble bracket; the thimble bracket on one end is connected with a fixed connection rod; one end of a tripod is connected with the fixed connection rod; the other end of the tripod is respectively connected with a pressing roller which is used for transferring spread long filament bunches to the splitting roller, a spreading roller which is used for spreading the long filament bunches and a locating yarn guider which is used for feeding the long filament bunches into a center position; and the fixed connection rod is arranged on a ring spinning frame. The invention further provides a composite spinning method and application for the yarn spreader. The yarn spreader provided by the invention can be used for spinning protective, soft, smooth and high-count composite yarns from ultrashort, easily-flaky and easily-flying fibers and shorter and weaker recycled fibers.

Owner:DONGHUA UNIV

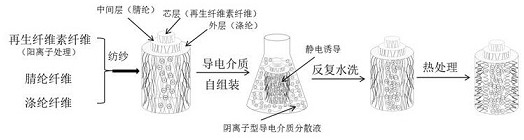

A kind of flexible conductive yarn and preparation method thereof

The invention relates to a flexible conductive yarn and a preparation method thereof. The conductive yarn constructs a three-layer concentric sheath core structure by using a mechanism of internal andexternal transfer of blended yarn. An outer layer is wrapped with a polyester staple fiber, which has good electrical insulation and mechanical properties, can effectively protect a core layer and isolates a current; the core layer is formed by a continuous regenerated cellulose fiber-based conductive medium and has good electrical conductivity; and an intermediate layer is composed of a heat-shrinkable acrylic fiber, which effectively stabilizes the yarn structure and isolates the conductive medium for protecting the core layer. The mechanism of internal and external transfer of the blendedyarn is utilized to construct the three-layer concentric sheath core structure to make the conductive yarn have excellent flexibility, stable structure and characteristics of being washable.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Coaxial tow net composite yarn prepared from tows in different numbers, spinning method and application

Owner:DONGHUA UNIV

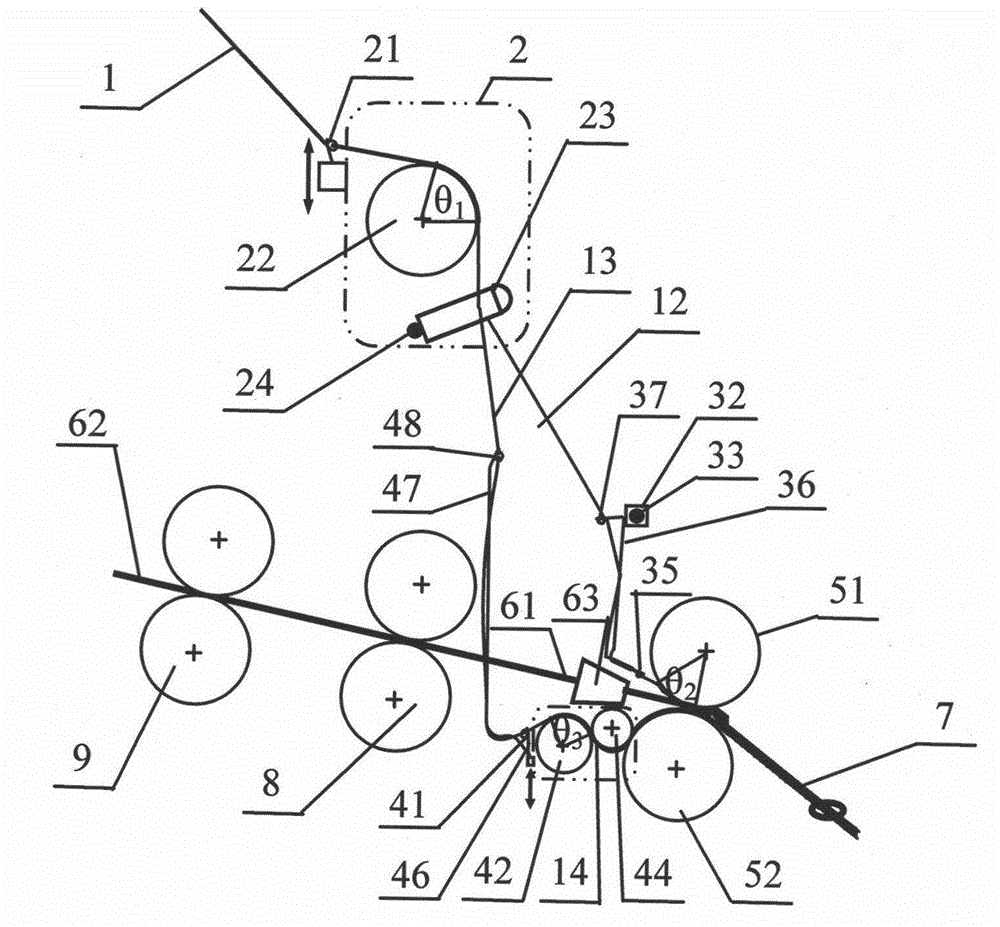

Composite yarn compounded by double yarns through using filament screens to cover downwards and support upwards, spinning method and application

The invention relates to a composite yarn compounded by double yarns through using filament screens to cover downwards and support upwards, a spinning method and application thereof. The composite yarn is a double-screen composite yarn with a 3*2 axis formed by clamping and wrapping short fiber yarns through a pair of double filament screens. The composite yarn with three types, consisting of double screen wrapping / double screen wrapping, screen-wrapping screen covering / screen-wrapping screen covering and double screen wrapping / screen-wrapping screen covering, can be woven into textiles and high-grade fine fabrics with clear texture, softness, abrasion resistance, high strength, anti-fluffing anti-pilling property, beautiful appearance and comfortableness. The method for producing the composite yarn comprises the following steps of: arranging a yarn guiding hook and a filament spreading device on a ring spinning frame, dividing four bunches of long filaments into two uplink bunches and two downlink bunches through the filament guiding hook, feeding the uplink bunches and the downlink bunches into respective filament spreader for spreading, forming two paths of covering filament screen and support filament screen, clamping and wrapping the respective short fiber yarns at a twisting triangular region, and compounding to form the double-screen composite yarn. The method provided by the invention is suitable for spinning protective, soft and smooth composite yarns from ultrashort, easily-flaky and easily-flying fibers and shorter and weaker recycled fibers.

Owner:DONGHUA UNIV

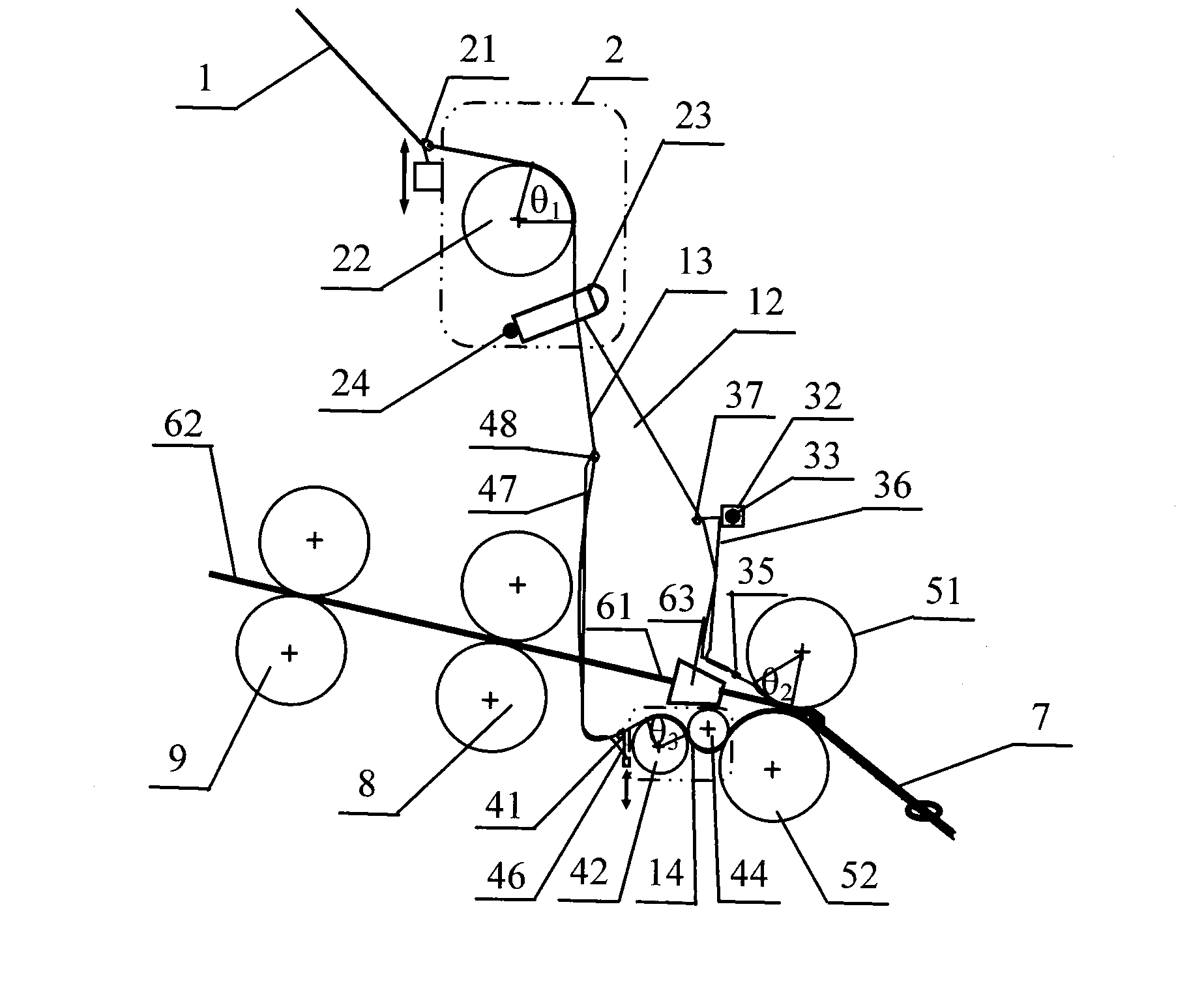

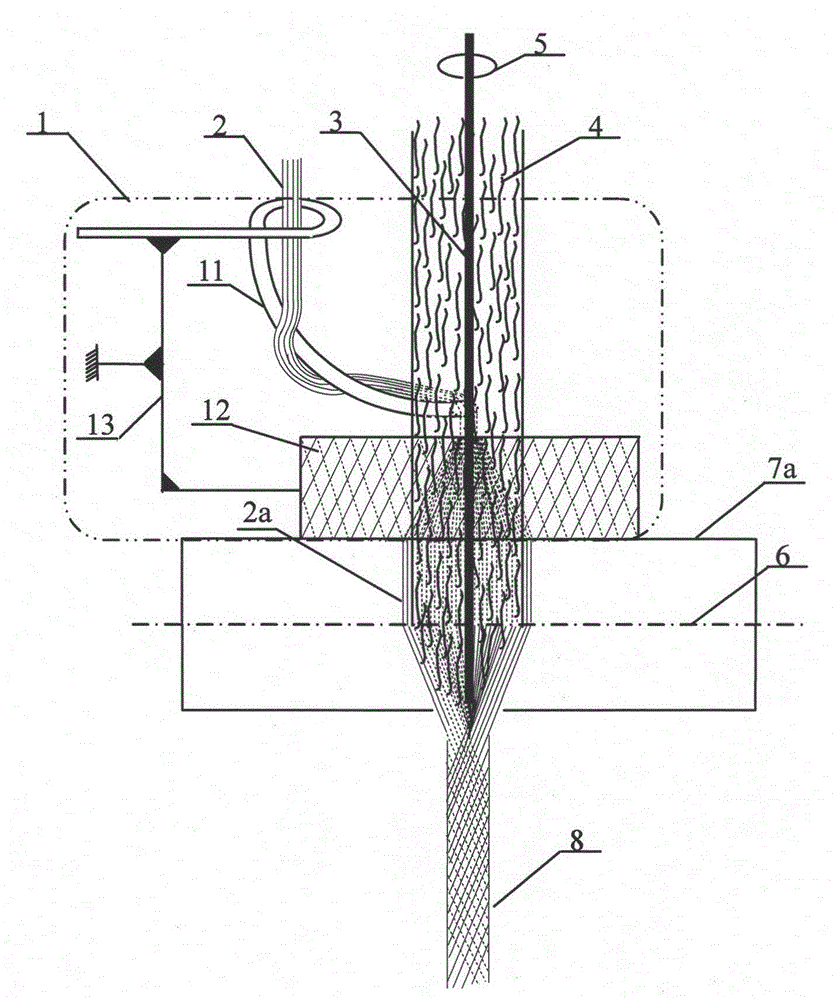

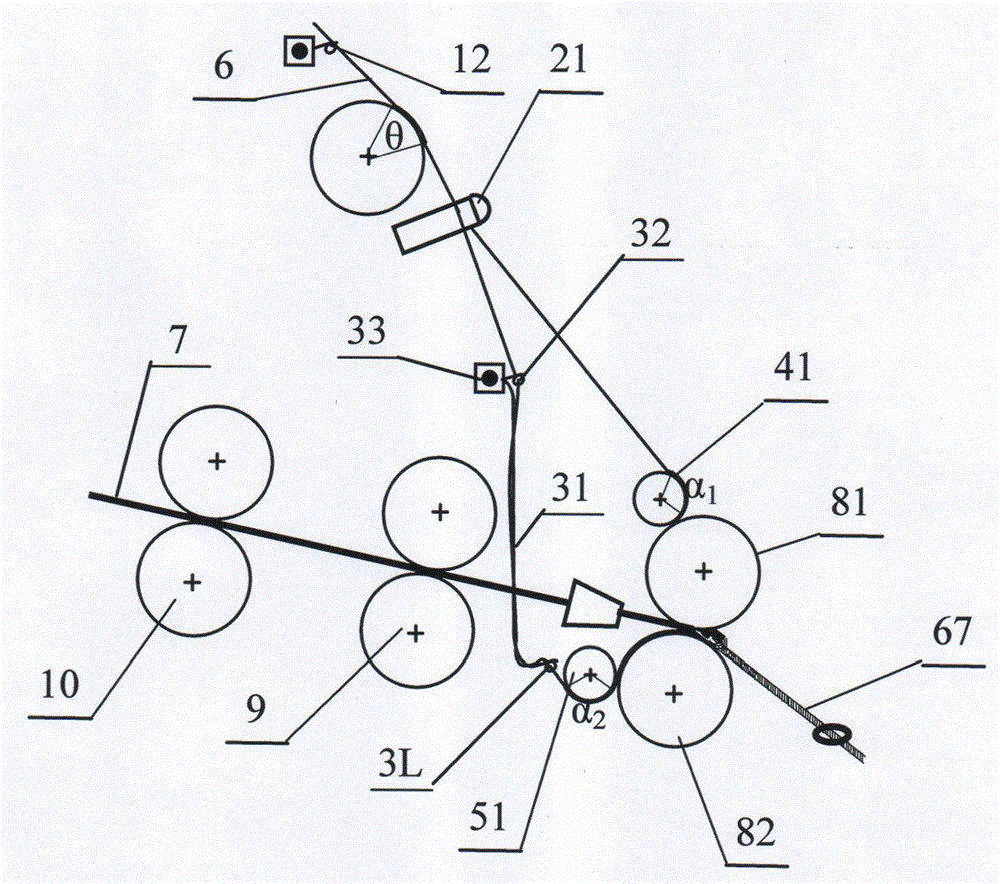

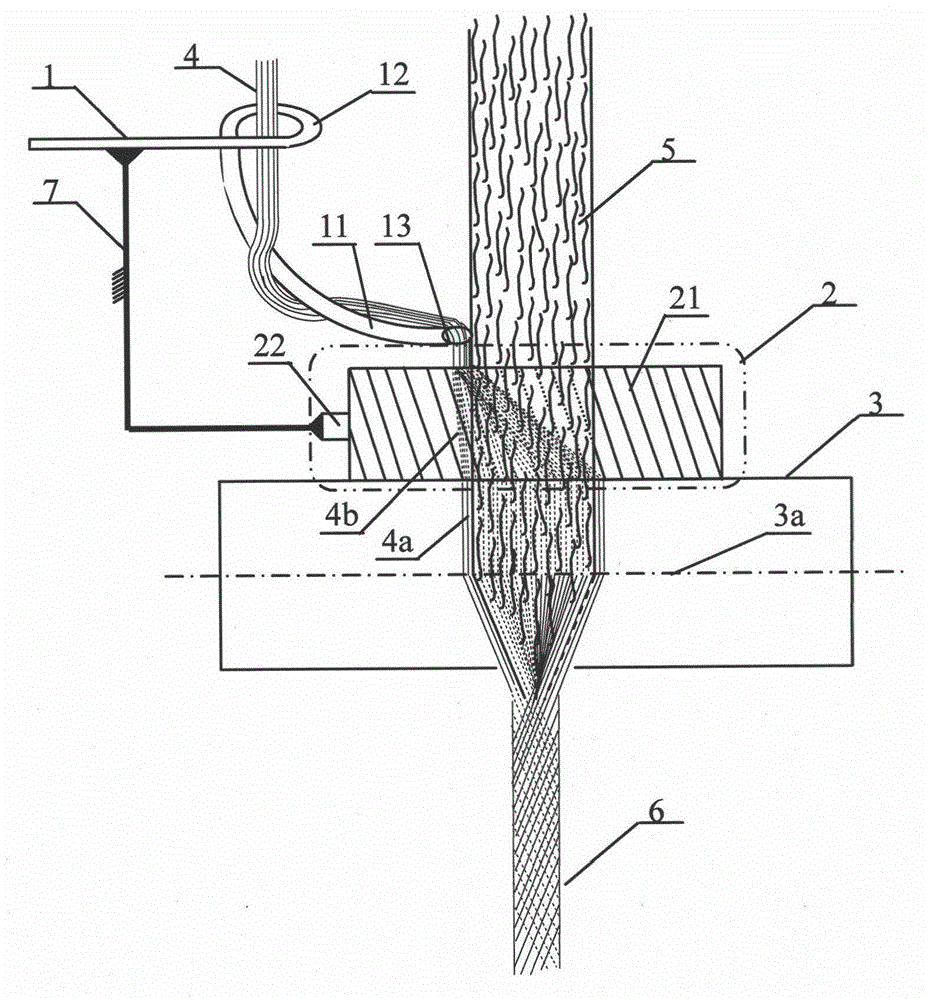

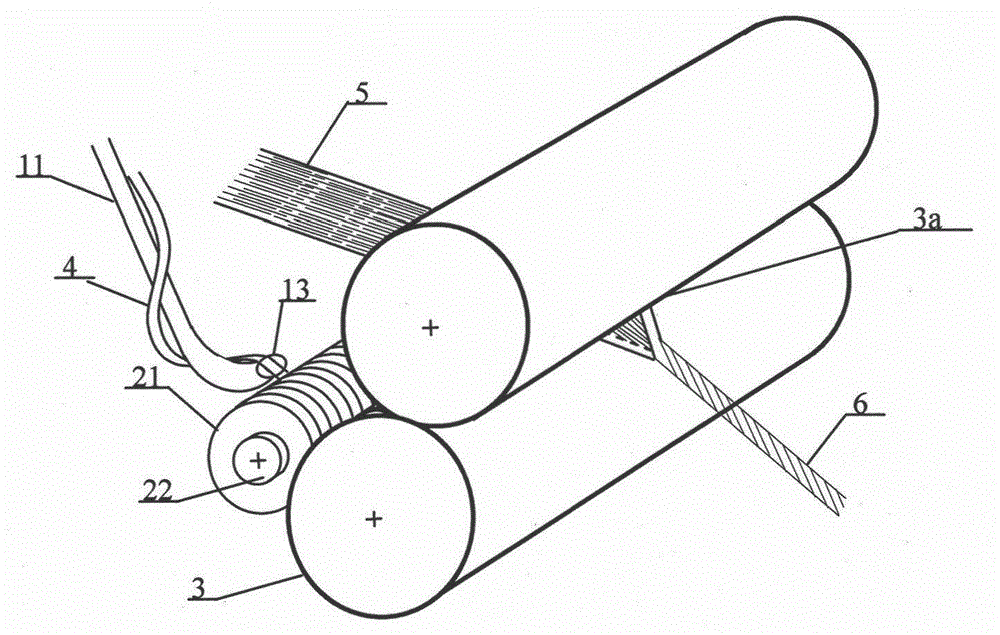

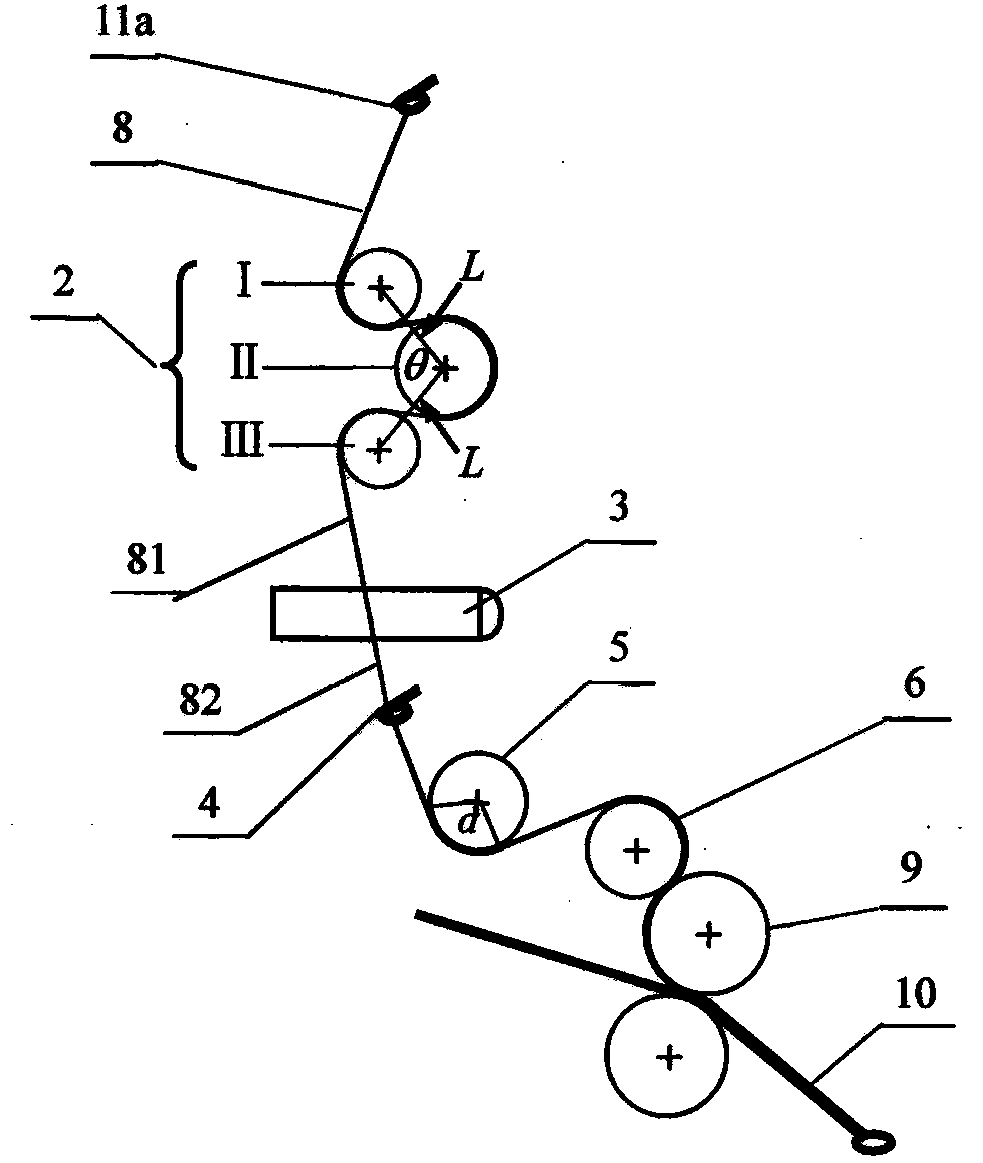

A Bottom Support Type Composite Spinning Mechanism, Method and Application of Filament Helically Expanded

The invention relates to a lower support type composite spinning mechanism for spirally spreading a filament, a process adopting the mechanism and application thereof. The mechanism is composed of a yarn guider and a screw-thread yarn spreading device. The technological steps are as follows: downwards guiding the filament through the yarn guider and guiding the filament into the threaded yarn spreading device located below a short fiber whisker strip; enabling the fed filament to spread uniformly along the screw thread by following the rotation of the screw-thread yarn spreading device to form a lower support filament mesh due to the guiding function of a screw thread and feeding the filament and the short fiber whisker strip passing above into a front roller synchronously; and wrapping the short fiber whisker strip on the lower filament mesh under the action of twisting to form a composite yarn. The mechanism is light, practical, and convenient to install and adjust, can improve fiber spinning efficiency and high count of the fibers efficiently, reduce flying, dropped chips and fluff in spinning and is suitable for composite spinning of high count soft and smooth yarns of shorter, weaker and ultra-short fibers.

Owner:DONGHUA UNIV

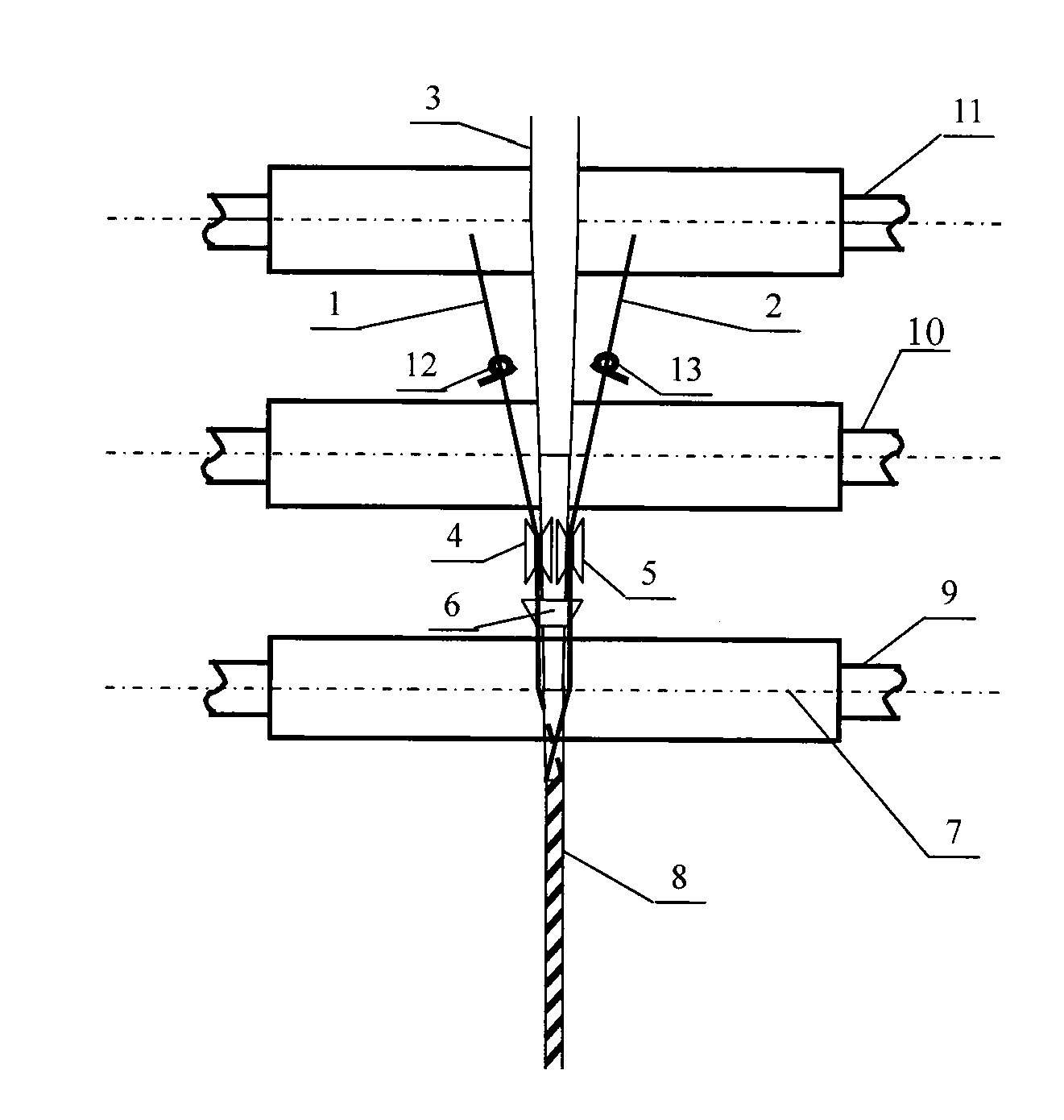

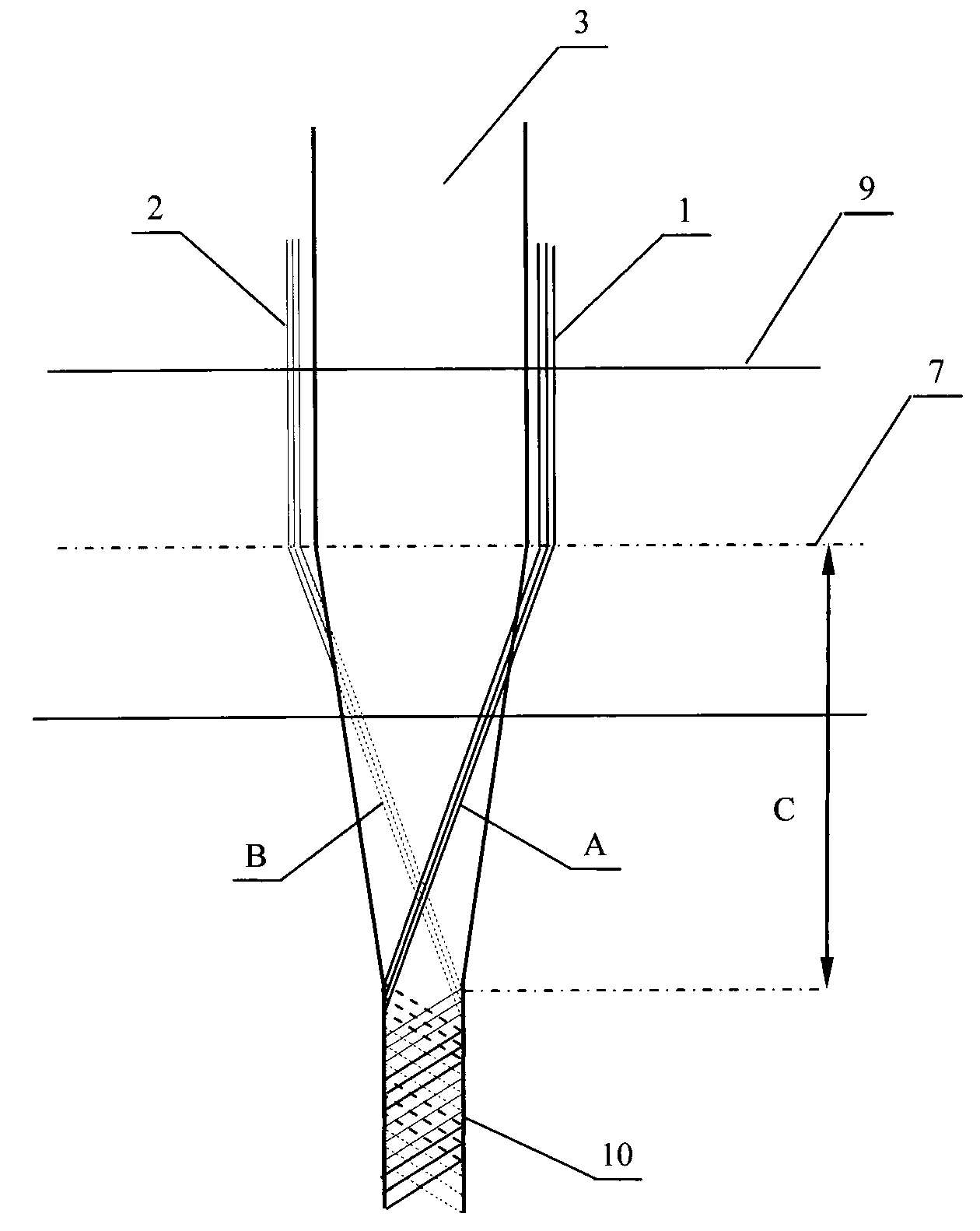

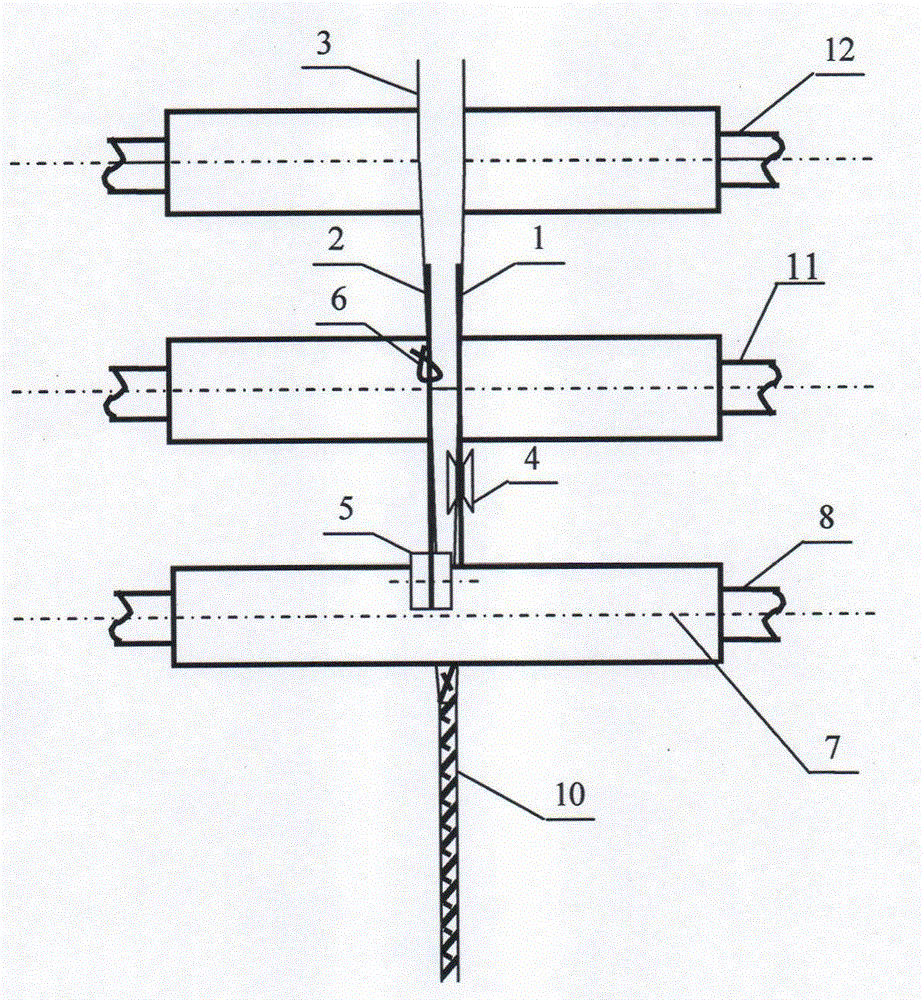

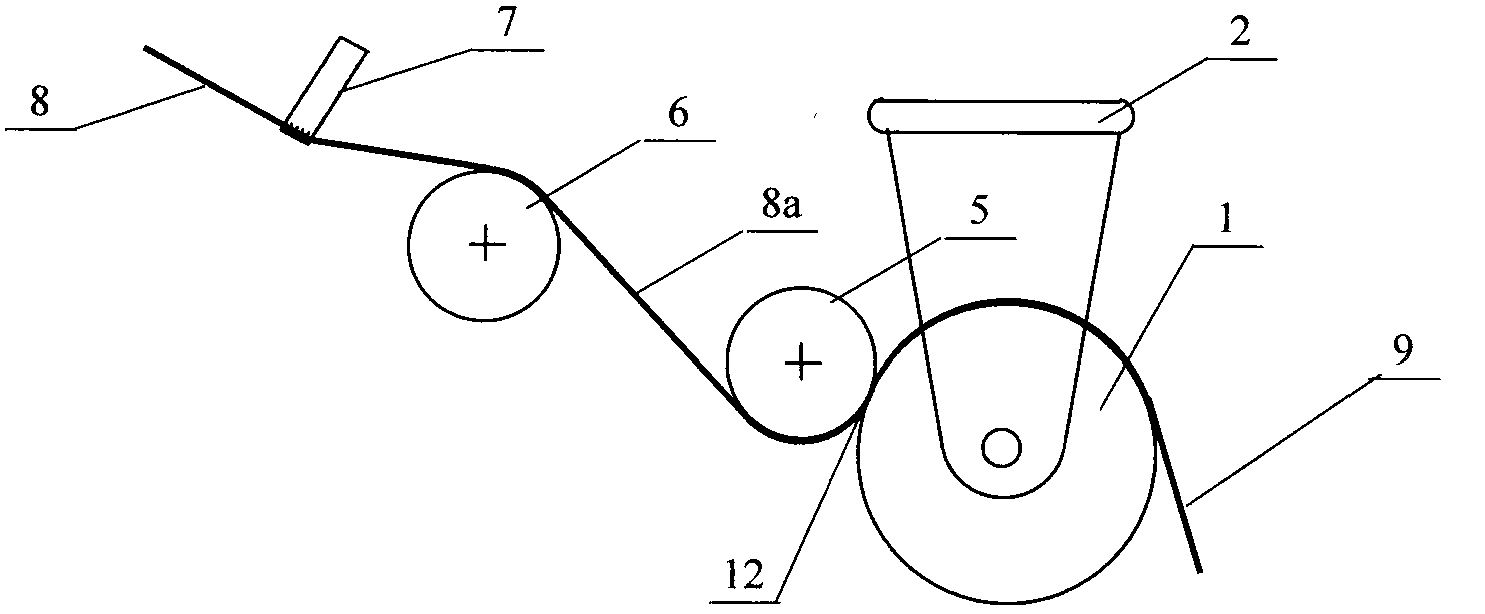

Smooth composite spinning mechanism and method of short fiber whisker strip clamped by double filaments via unequal tension

The invention relates to a smooth composite spinning mechanism, method and application of a short fiber whisker strip clamped by double filaments via unequal tension. The mechanism is composed of a tension disk used for locating a tension filament and controlling tension thereof, a yarn guide hook used for locating a low-tension filament and a holding roller used for keeping the tension. The composite spinning method comprises the steps of: synchronously feeding the tension filament, the low-tension filament as well as the short fiber whisker strip into a front roller to enable the short fiber whisker strip to be wrapped by the two filaments in a traction zone; and forming a three-shafting spinning yarn with the short fiber whisker strip covered by the tension filament from the upside and support by the low-tension filament from the downside, wherein the composite yarn is a smooth composite yarn which is formed by spirally twisting the tension filament and the short fiber whisker strip and externally coating the low-tension filament. The mechanism is light, practical, convenient to install, controllable and adjustable, can produce yarns with steady structure and is suitable for composite spinning of high-count smooth yarns and superfine yarns of short fibers.

Owner:DONGHUA UNIV

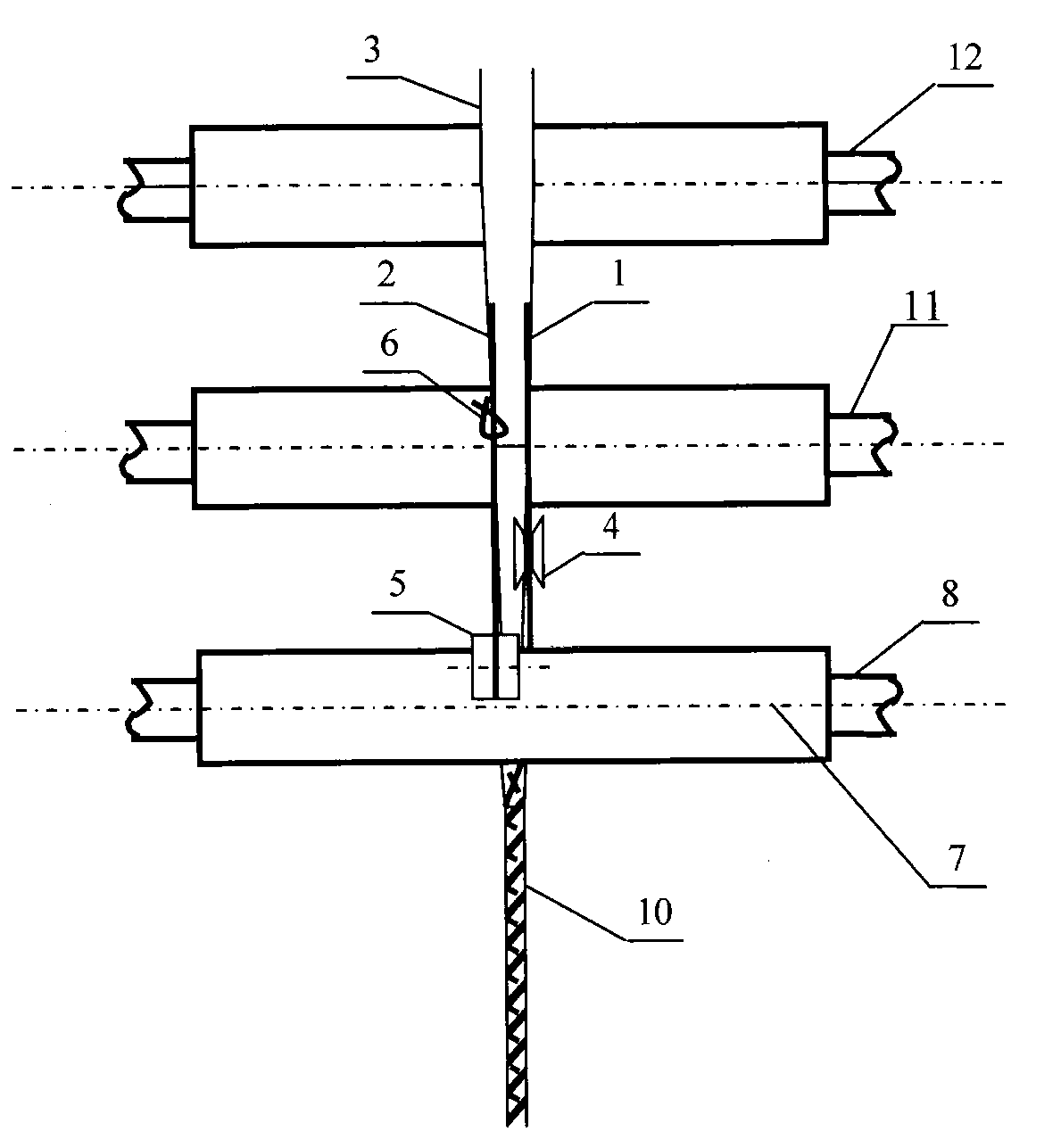

Upper covering type splitting yarn spreader for yarns, method and application

The invention relates to an upper covering type splitting yarn spreader for yarns. The yarn spreader is characterized by comprising a splitting roller, wherein the left end and the right end of the splitting roller are respectively provided with a thimble bracket; the thimble bracket on one end is connected with a fixed connection rod; one end of a tripod is connected with the fixed connection rod; the other end of the tripod is respectively connected with a pressing roller which is used for transferring spread long filament bunches to the splitting roller, a spreading roller which is used for spreading the long filament bunches and a locating yarn guider which is used for feeding the long filament bunches into a center position; and the fixed connection rod is arranged on a ring spinning frame. The invention further provides a composite spinning method and application for the yarn spreader. The yarn spreader provided by the invention can be used for spinning protective, soft, smooth and high-count composite yarns from ultrashort, easily-flaky and easily-flying fibers and shorter and weaker recycled fibers.

Owner:DONGHUA UNIV

Coaxial bidirectional filament spreading device of beam-splitting filament and application

Owner:DONGHUA UNIV

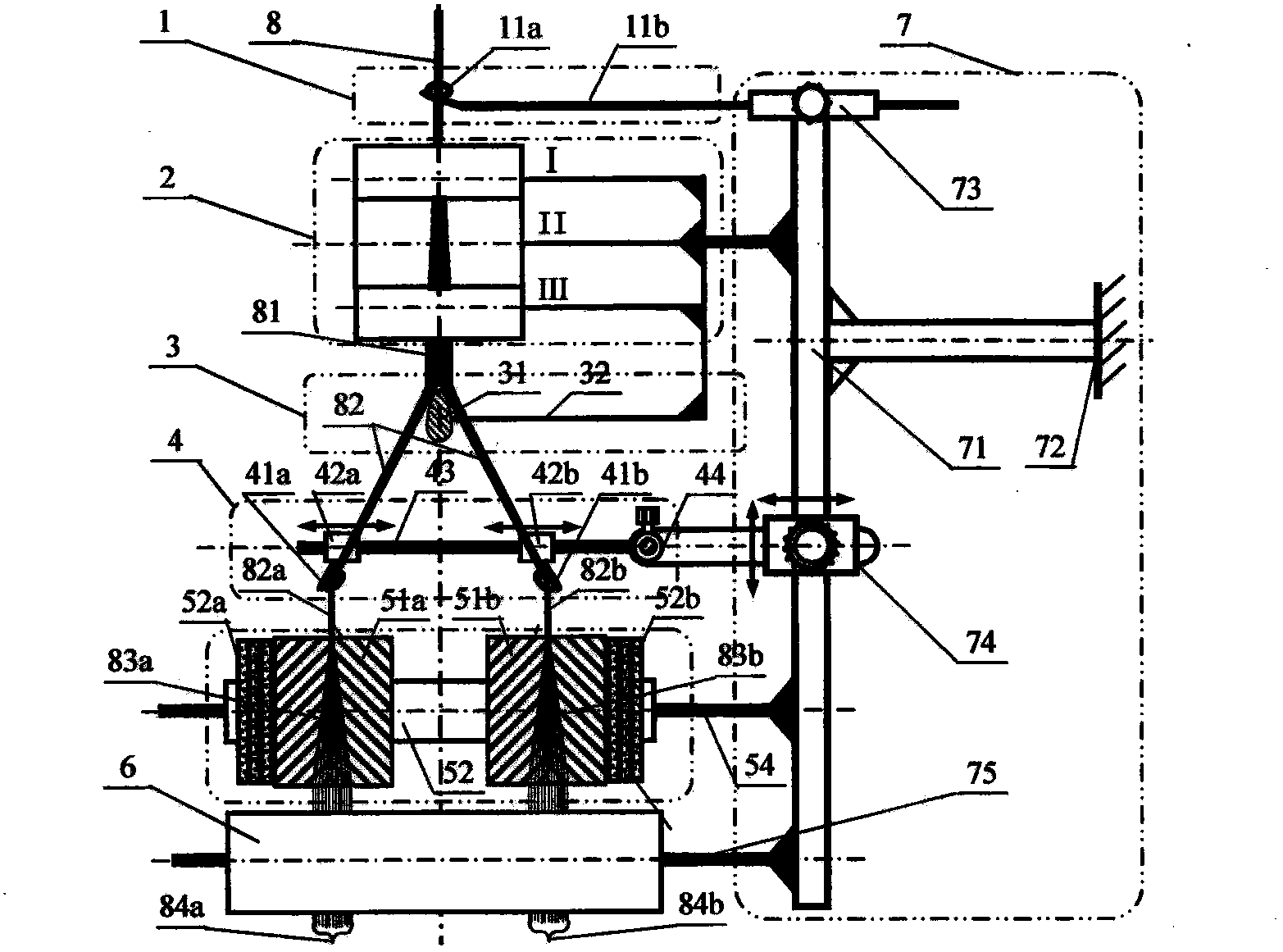

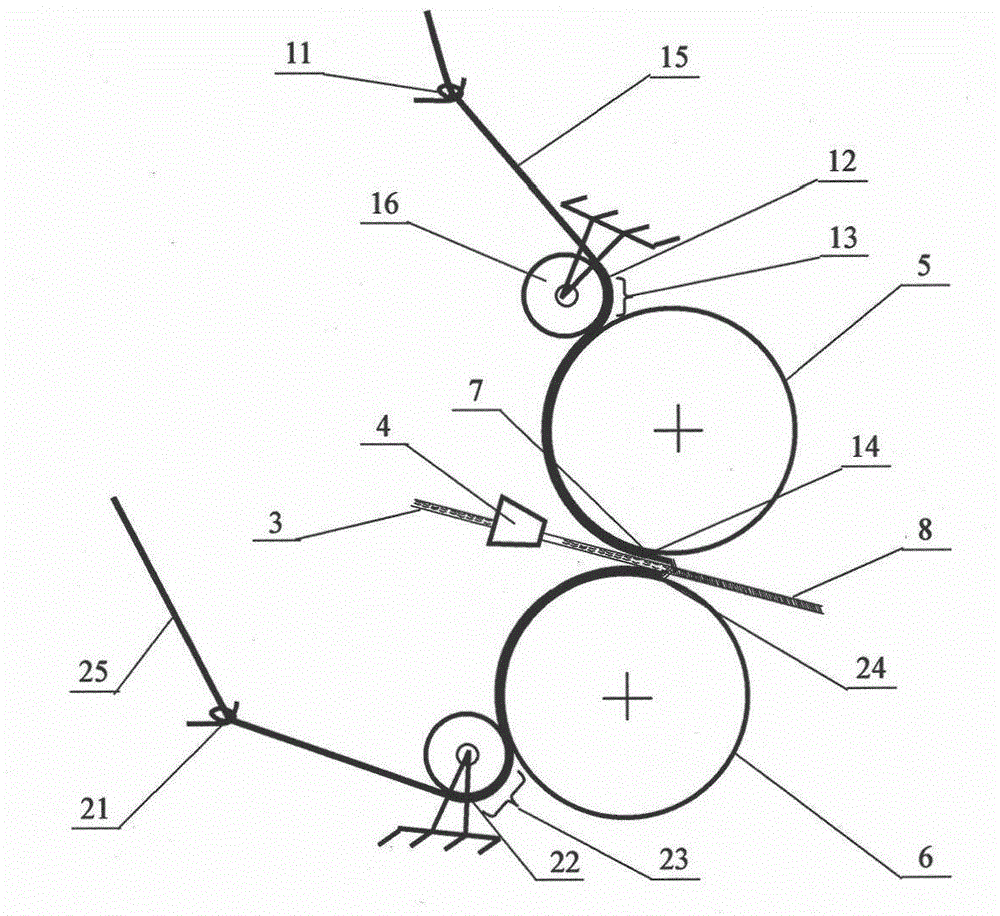

Two-roller differential two-stage split yarn spreader, spinning method and its application

The invention relates to a twin-roll differential type two-stage splitting yarn unfolding device, a spinning method and application of twin-roll differential type two-stage splitting yarn unfolding device. The twin-roll differential type two-stage splitting yarn unfolding device consists of a positioning a yarn guiding hook, two symmetrical splitting rolls for unfolding the yarns and clutches thereof, a differential mechanism for carrying out transmission on two split rolls as well as a fixing frame for mounting various parts of the yarn unfolding device on a ring spinning frame. According to the spinning method, long filaments are positioned at the splitting midline of a primary splitting roll through a yarn guiding hook; primary splitting and yarn unfolding are finished by winding; and then secondary splitting and yarn unfolding are finished by symmetrically winding and secondarily splitting roll. Due to the utilization of speed difference of the two splitting rolls, the splitting and yarn unfolding can be effectively and controllably realized under the rotation of splayed threads. The yarn unfolding device can be applied to spinning of protective, soft and smooth and high-count composite yarns formed by super-short fibers, fibers which easily fall scrip and easily fly as well as extremely-short and extremely-weak reclaimed fibers.

Owner:DONGHUA UNIV

Filament beam splitting two-axis unfolding device and application

The invention relates to a filament beam splitting two-axis unfolding device and application thereof. The unfolding device comprises a central snail wire, a flattening roller set, a splitting rod, a pair of snail wires which are used for guiding a two-axis filament, a pair of unfolding rollers and a driving roller, and the unfolding device is connected to a fixation support and is arranged on a ring spinning frame by virtue of the fixation support. A method for realizing filament beam splitting two-axis unfolding is characterized in that a filament is located on a central line of the flattening roller set by virtue of the central snail wire, a tow is unfolded by virtue of the flattening roller set; then the tow is symmetrically split into two tows by virtue of the splitting rod, the two tows are fed by virtue of the snail wires in a way of aligning the central line of each screw thread in an'inverted V' shape, the two tows are unfolded into a silk screen by virtue of the unfolding rollers; and the silk screen is output around the driving roller appressed to a front roller. The unfolding device can be applied to spinning of super-short, easy-flaky and easy-flying fibers, shorter and weak recycling fibers and protective, soft, smooth, high count and superlow count composite yarn.

Owner:DONGHUA UNIV

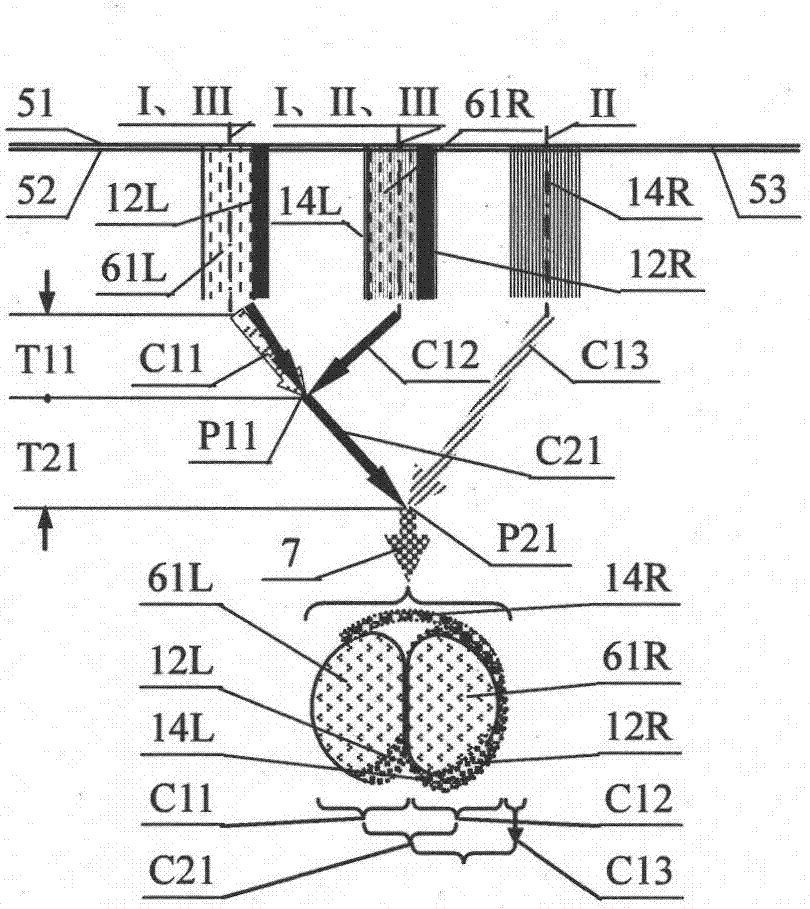

Symmetrical beam splitting filament-spreading synchronous upper-covering and lower-supporting composite yarn, spinning method and application

The invention discloses a symmetrical beam splitting filament-spreading synchronous upper-covering and lower-supporting composite yarn, a spinning method and application thereof. The composite yarn is a pair of 3*2 shafting double-mesh composite yarn which is formed by compounding after a short fiber whisker strip is wrapped by double filament meshes and halving a filament, that is to say, a two double-mesh wrapping, two-mesh wrapping and coating, double-mesh wrapping and mesh wrapping and coating composite yarn; and the yarn can be used for weaving soft, abrasion-resistant, beautiful and comfortable textile with clear texture, high intensity and pilling resistance and high-level fine fabrics. The method for realizing the double-mesh composite yarn comprises the steps of: adopting a splitter and filament spreading devices both of which are mounted on a ring throstle; symmetrically splitting two beams of the filaments into four beams including two upstream beams and two downstream beams by the splitter; enabling the upstream beams and the downstream beams to enter into respective filament spreading devices for filament spreading so as to form tow paths of upper-covering and lower-supporting filament meshes and clamp as well as wrap respective short fiber whisker strip in a twisting triangular zone; and then compounding to form the double-mesh composite yarn. The method is suitable for spinning of protective, soft, smooth and high-count composite yarns of fibers which are ultra-short, easy to drop scraps and easy to generate flying and shorter and weaker fibers.

Owner:DONGHUA UNIV

Top covering and bottom supporting type three-shafting composite yarn, spinning method and applications thereof

The invention relates to a top covering and bottom supporting type three-shafting composite yarn and a spinning method thereof. The composite yarn is of a three-shafting composite spun yarn prepared by using an upper-layer filament and a lower-layer filament to clamp and protect chopped fiber strands, so that the formed filament is of a composite yarn in form of cored layer chopped fiber strands being wound by the filaments. The spinning method comprises the steps of firstly installing a top covering yarn spreader, a bottom supporting yarn spreader and a clustering device on a common fine yarn spinning machine; then spreading two filament clusters by an upper yarn spreading roll and a lower yarn spreading roll into two filament layers, synchronously feeding in a front roller jaw together with chopped fiber strand passing through the clustering device in three-shafting manner, and respectively using the two filament layers to clamp the chopped fiber strands by means of top covering and bottom supporting; and when the two filament layers and the chopped fiber strands come out the front roller jaw, forming composite yarns in form of the chopped fiber strands being wound by the two filament layers under twisting action. The method is applicable to spinning of protective type soft, smooth and high-count composite yarns for ultrashort fibers which are easy to fall crumbs and easy to fly, as well as shorter and weaker reclaimed fibers.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com