A kind of flexible conductive yarn and preparation method thereof

A flexible conductive and yarn technology, applied in the field of flexible wearable electronic devices, can solve problems such as limitations, and achieve stable electrical properties, good electrical insulation and mechanical properties, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

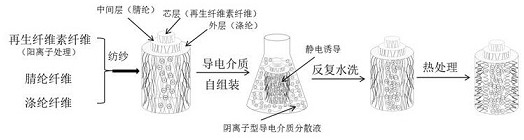

[0023] The preparation method of flexible conductive yarn, the steps are as follows:

[0024] Put the viscose fiber with a length of 48mm and a fineness of 0.9D in a solution composed of a cationic modifier with a concentration of 0.5% and a temperature of 50°C for 30 minutes, wash with water and dry, and combine with a length of 40mm and a fineness of 1.2D acrylic fiber and polyester fiber with a length of 34mm and a fineness of 1.5D are mixed in the drawing process at a blending ratio of 40 / 10 / 50, and a multi-component with three-layer concentric sheath-core structure is obtained through roving and spinning processes Spun yarn. Then place the multi-component spun yarn in the conductive medium dispersion liquid which is anionic carbon nanotubes, the concentration of the dispersion liquid is 0.5%, the temperature is 20°C, and it is treated for 30 minutes. After washing, it is dried at room temperature, and the treatment is repeated five times. The process prepares the conduct...

Embodiment 2

[0026] The preparation method of flexible conductive yarn, the steps are as follows:

[0027] (1) Cationic treatment: place regenerated cellulose fibers with a length of 46mm and a fineness of 0.9D in a chitosan solution with a concentration of 0.5% and a temperature of 50°C for 60 minutes, wash with water and then dry;

[0028] (2) Blending: The regenerated cellulose fiber after cationic treatment, length 40mm, fineness 1.2D bean curd acrylic fiber (bulky yarn), length 34mm, polyester staple fiber 1.5D fineness are mixed and spun into multi- Component yarn, regenerated cellulose fiber is placed in the core layer of multi-component yarn, acrylic fiber is in the middle layer, polyester staple fiber is distributed in the outer layer; the blending ratio of regenerated cellulose fiber, acrylic fiber and polyester staple fiber is 40:10 :50;

[0029] (3) Conductive medium self-assembly treatment: The multi-component yarn is repeatedly dipped in anionic carbon nanotube dispersion fo...

Embodiment 3

[0032] The preparation method of flexible conductive yarn, the steps are as follows:

[0033] (1) Cationic treatment: place regenerated cellulose fibers with a length of 48mm and a fineness of 0.95D in a DMAC solution with a concentration of 0.8% and a temperature of 70°C for 50 minutes, wash with water and then dry;

[0034] (2) Blending: The cationic-treated regenerated cellulose fiber, length 42mm, fineness 1.25D bean curd acrylic fiber (bulky yarn), length 35mm, polyester staple fiber 1.55D fineness are mixed and spun into multi- Component yarn, regenerated cellulose fiber is placed in the core layer of multi-component yarn, acrylic fiber is in the middle layer, polyester staple fiber is distributed in the outer layer; the blending ratio of regenerated cellulose fiber, acrylic fiber and polyester staple fiber is 40:10 :50;

[0035] (3) Conductive medium self-assembly treatment: The multi-component yarn is repeatedly dipped in the anionic graphene dispersion for self-assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com