A kind of mixed type papermaking pigment and preparation method thereof

A mixed-type, mixed slurry technology, applied in the field of papermaking pigments, can solve the problems of narrow particle size distribution range, agglomerated pulp lumps, etc., achieve the effects of narrow particle size distribution range, improve performance, and reduce the content of large particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

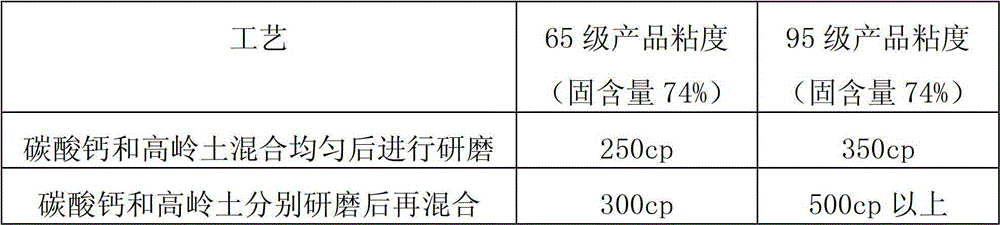

Method used

Image

Examples

Embodiment 1

[0035] Calcium carbonate, washed kaolin and water are mixed to obtain a slurry with a solid content of 78%, and the above slurry is discharged to the buffer tank; the slurry in the buffer tank is subjected to open circulation grinding, that is, the slurry comes out of the buffer tank Finally, it enters the grinding equipment for grinding, and the ground slurry is transported back to the buffer tank by the delivery pump, and a dispersant is added during the grinding process. The amount of the dispersant added is 1.0% of the dry weight. When the ground slurry After the content of particles with a particle size of less than 2 μm is ≥95%, stop grinding; finally, sort the slurry after grinding to remove large particles: the slurry after grinding first enters the screening equipment for a sorting treatment, and then enters the centrifuge Machine for refined secondary sorting.

[0036] The main indicators of grade 95 paper-making pigments obtained by the above process are: the solid ...

Embodiment 2

[0038] Calcium carbonate, washed kaolin and water are mixed to obtain a slurry with a solid content of 76%; the mixed slurry is ground, and a dispersant is added during the grinding process, and the amount of the dispersant added is 0.3% of the dry weight ;When the content of particles with a particle size of less than 2 μm in the ground slurry is ≥65%, stop grinding; finally, sort the ground slurry to remove large particles, and the ground slurry first enters the screening equipment for First sorting treatment, and then into the centrifuge for refined secondary sorting treatment.

[0039] The main indicators of grade 65 paper-making pigments obtained by the above process are: the solid content of paper-making pigments is 75.8%, the weight ratio of calcium carbonate and kaolin is 95:5, the particle size is less than 2μm, the content is 66%, and the 45μm water sieve residue 0.003%.

Embodiment 3

[0041] Mix calcium carbonate, washed kaolin and water to obtain a slurry with a solid content of 80%, and discharge the above slurry to the buffer tank; carry out open circulation grinding on the slurry in the buffer tank, that is, the slurry comes out of the buffer tank Finally, it enters the grinding equipment for grinding, and the ground slurry is transported back to the buffer tank by the delivery pump, and a dispersant is added during the grinding process. The amount of the dispersant added is 1.5% of the dry weight. When the ground slurry After the content of particles with a particle size of less than 2 μm is ≥95%, stop grinding; finally, sort the slurry after grinding to remove large particles: the slurry after grinding first enters the screening equipment for a sorting treatment, and then enters the centrifuge Machine for refined secondary sorting.

[0042] The main indicators of grade 95 paper-making pigments obtained by the above process are: the solid content of pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com