Method for drying domestic waste and drying drum for same

A technology for drying drums and wastes, applied in the field of drying drums for household wastes, can solve problems such as inapplicability, and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Application DE 10 2007 010 070 A1 is a description of the structural design of an MPS plant, the components of said plant and the methods used in this plant, in particular with regard to the tumble dryer, which is hereby incorporated by reference in its entirety.

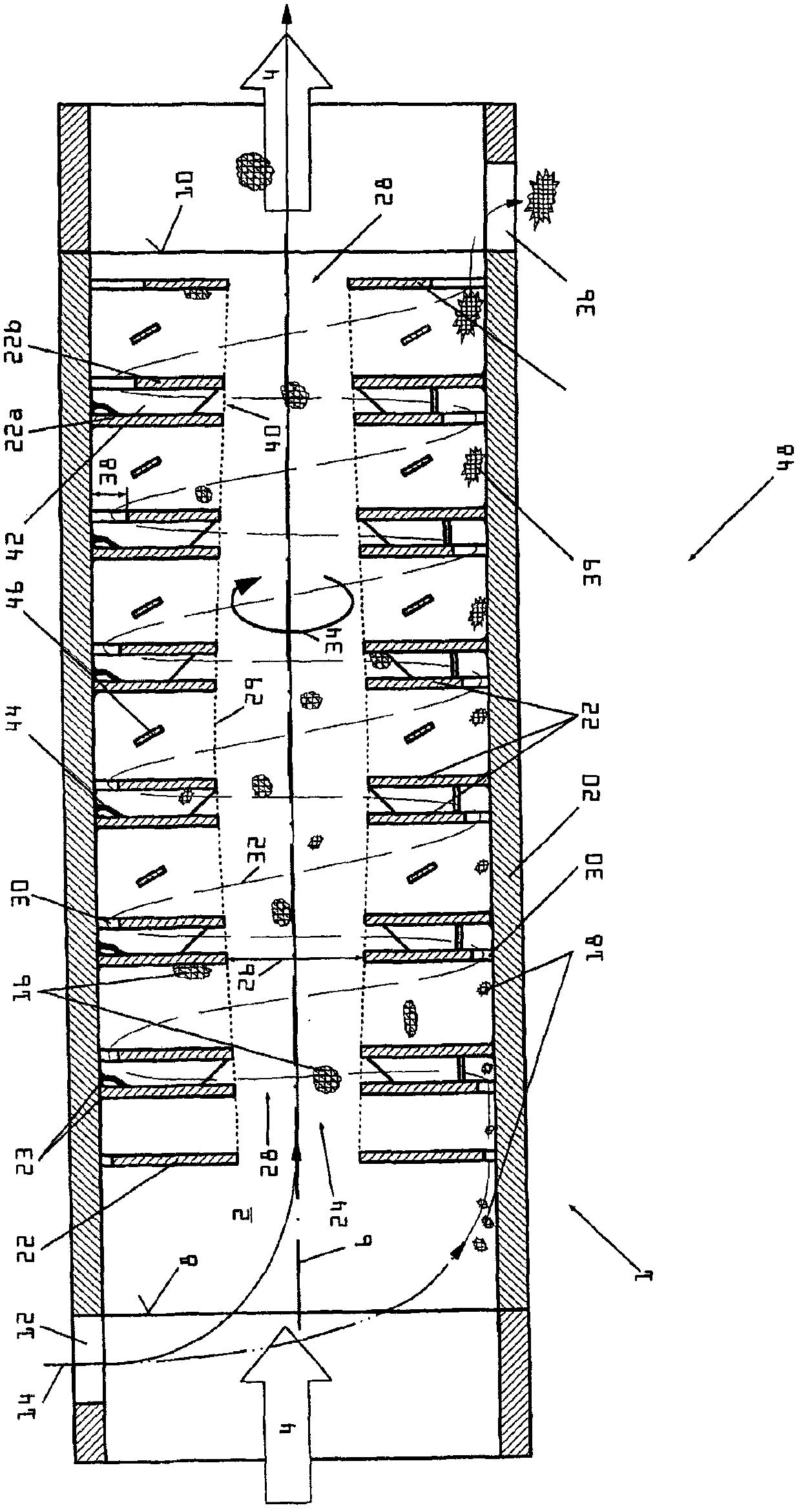

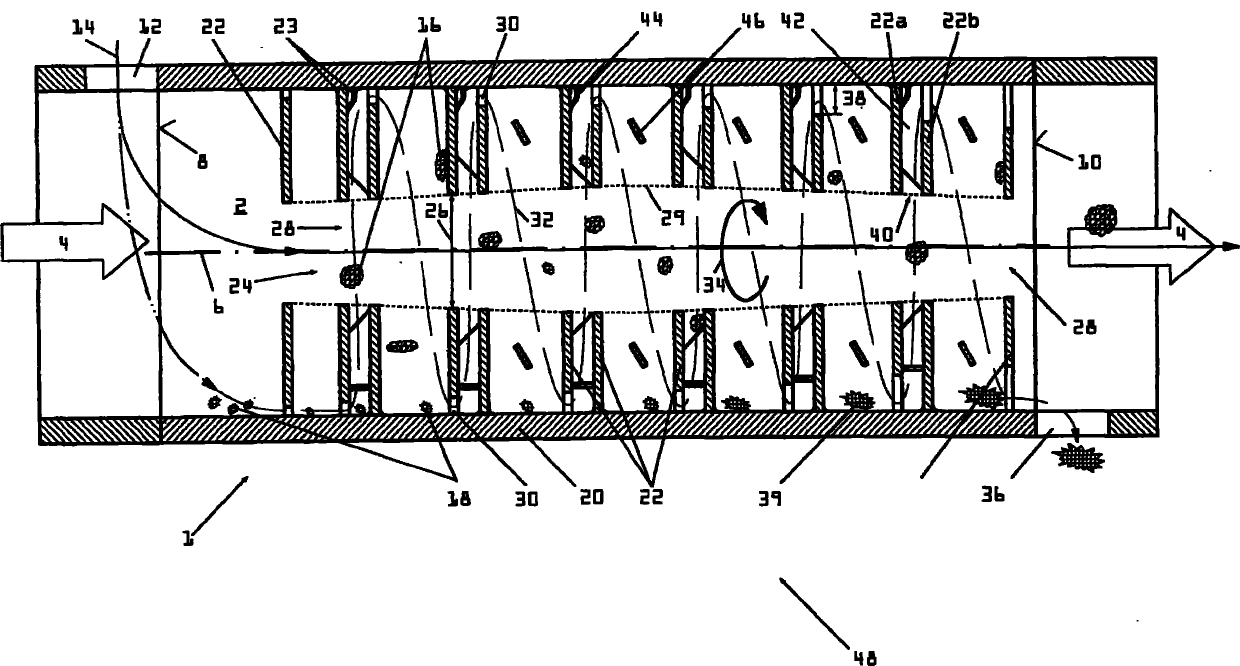

[0076] The drying drum 1 has an interior space 2 through which a hot air flow flows in a longitudinal direction 6 . The hot air flow 4 enters the interior space 2 through an upstream inlet 8 , from which it is discharged through an outlet 10 . Depending on the composition of the household waste varying from one area to an adjacent area, the temperature of the hot air stream 4 can vary from 300°C to 500°C. The speed of the hot air flow can be between 20m / s and 40m / s. The object to be achieved is shock drying of the material flow. To ensure this, the material flow is controlled within the drying drum by means of process variables such as temperature and humidity. For example, if the temperature drops and / or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com