Relevant method for improving signal-to-noise ratio of passive nucleon level gage

A material level gauge and signal-to-noise ratio technology, which is applied in the field of improving the signal-to-noise ratio of passive nuclear material level gauges, can solve problems such as the inability to fundamentally eliminate the influence of environmental rays on material level measurement, and achieve the elimination of environmental impacts and increase reliability. Reliability, the effect of increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with the accompanying drawings, and its methods can be realized by those skilled in the art.

[0026] The invention provides three sets of methods that can be replaced with each other according to the actual situation, and is based on the improvement of the existing passive nuclear material level meter measurement and calculation method.

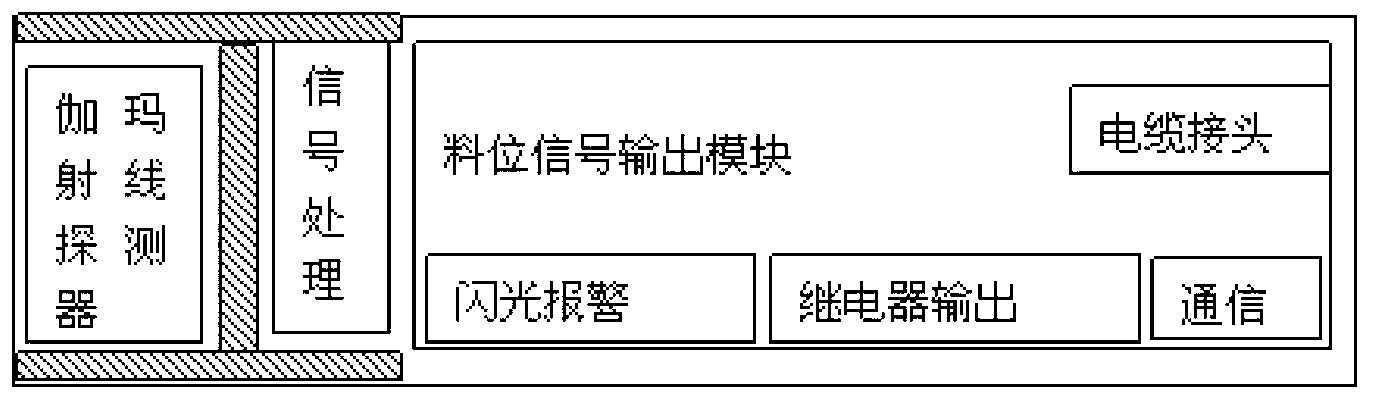

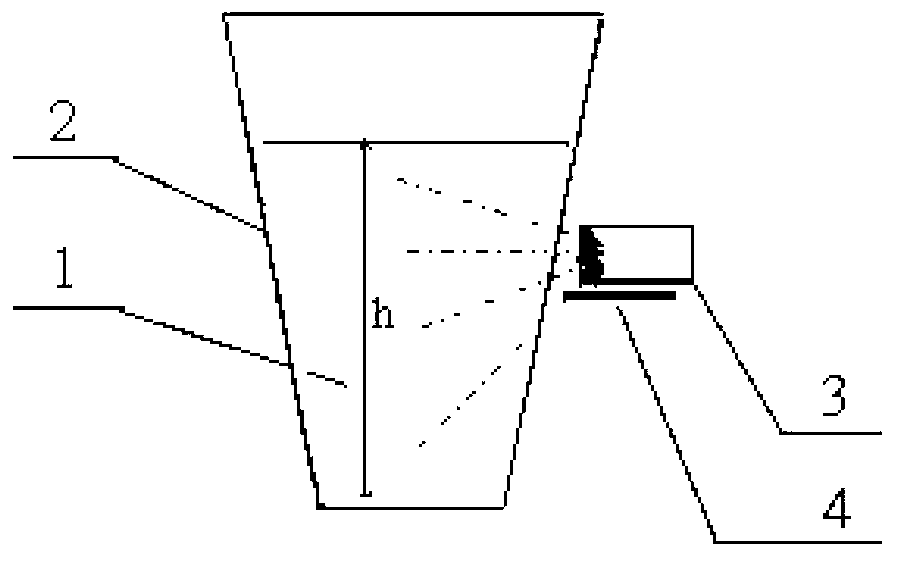

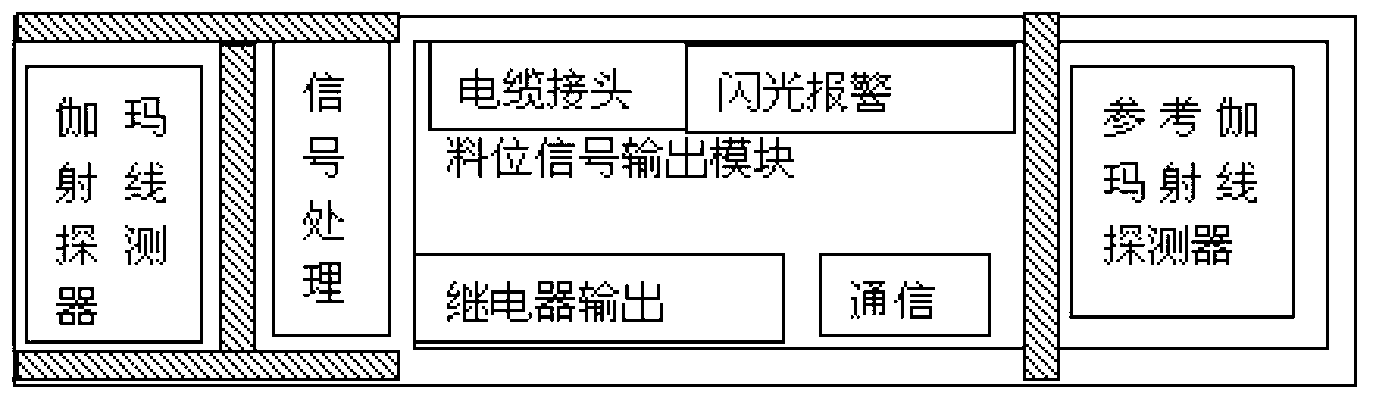

[0027] The passive nuclear material level meter used in the embodiment is as figure 1 It mainly includes: (1) Gamma ray detector, choose NaI scintillation detector, used to measure the gamma ray intensity of the measured material and the environment where the measured container is located; (2) Signal processing module, used to process the collected The gamma ray intensity signal, combined with the electronic circuit that sends out the alarm signal according to the preset switch point, cancels the alarm signal, or outputs the continuous material level signal according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com