Test device for verifying the cooling and heating cycle performance of engine radiators

A technology of cold and heat cycle and test device, applied in the field of automobiles, can solve the problems of insufficient guarantee of product quality, short product development cycle, insufficient verification, etc., and achieve the effect of simple structure, low cost and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

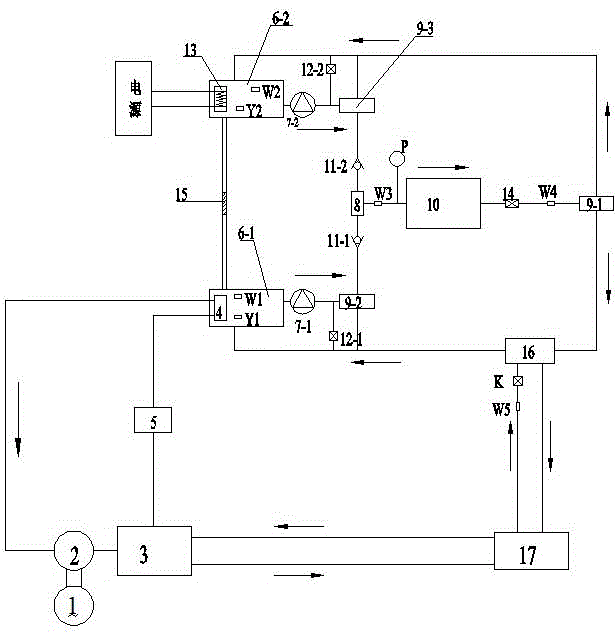

[0035] This embodiment is a test device for verifying the cooling and heating cycle performance of the engine radiator, and its structural connection block diagram is as follows figure 1 shown.

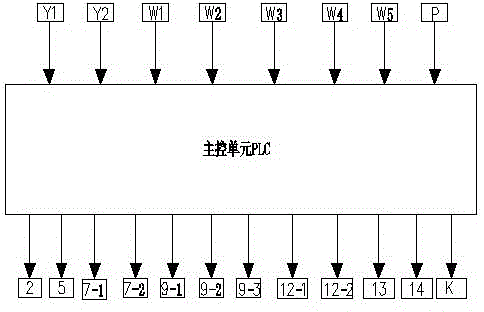

[0036] The test device includes a cooling circuit for providing cold water for the radiator's cold and hot cycle performance test, a main circuit for the radiator's cold and hot cycle performance test, and a primary cooling device for the water flowing back to the cold water tank in the cold water cycle. An external circulating water circuit and a control system for controlling the work of the whole device. in:

[0037] (1) The cooling circuit includes motor 1, compressor 2, condenser 3 and evaporator 4. The output power of the motor 1 is connected to the compressor 2, the outlet of the compressor 2 is connected to the inlet of the condenser 3, the outlet of the condenser 3 is connected to the inlet of the evaporator 4 through the expansion valve 5, and the outlet of the evaporator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com