High-speed impact film tribology testing machine and method for evaluating film impact frictional property

A high-speed impact and impact friction technology, which is applied in the direction of testing wear resistance, scientific instruments, strength characteristics, etc., can solve the problems of inability to evaluate impact tribological properties, etc., and achieve the effect of compact structure, high precision and strong function expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, rather than limiting it in any way.

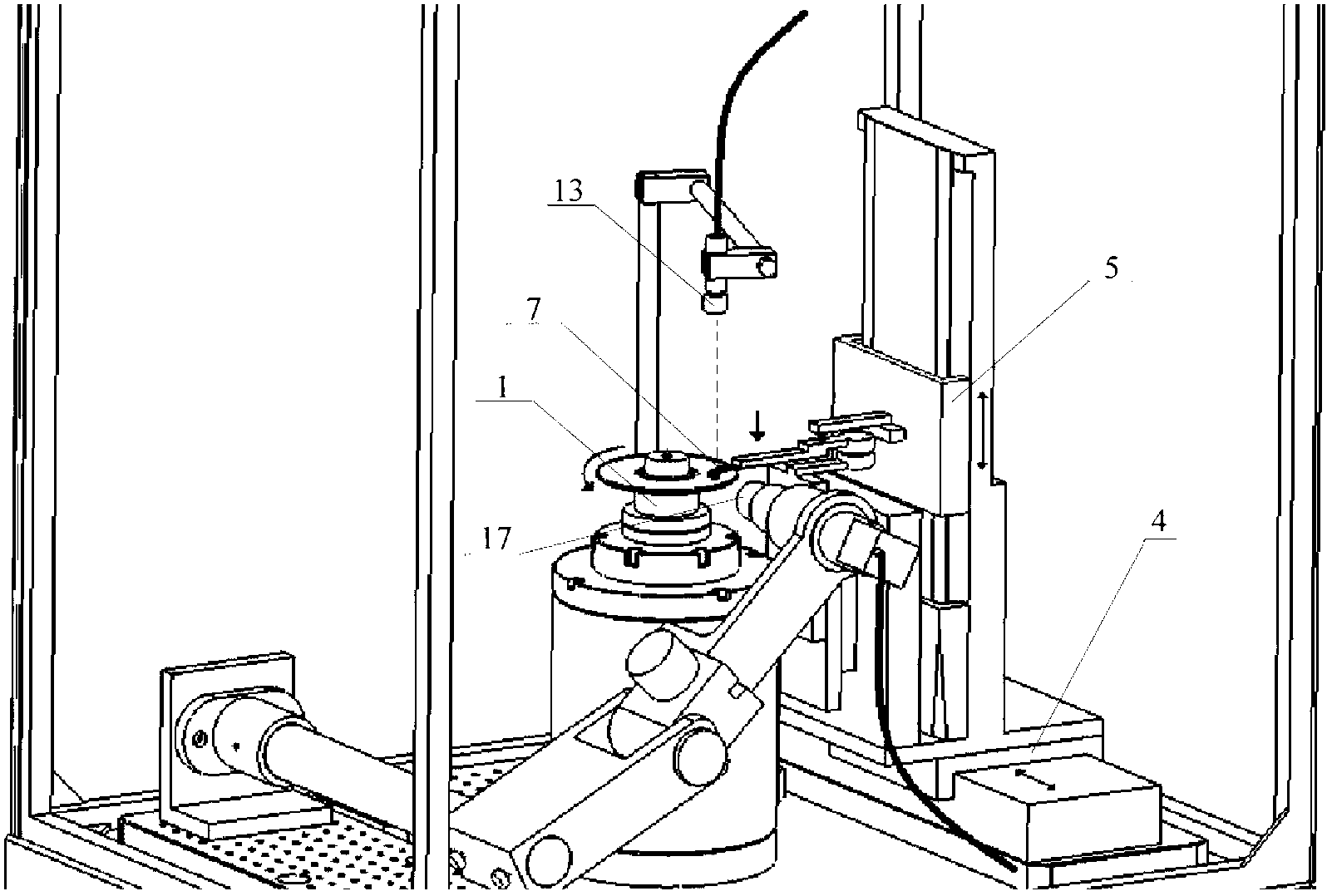

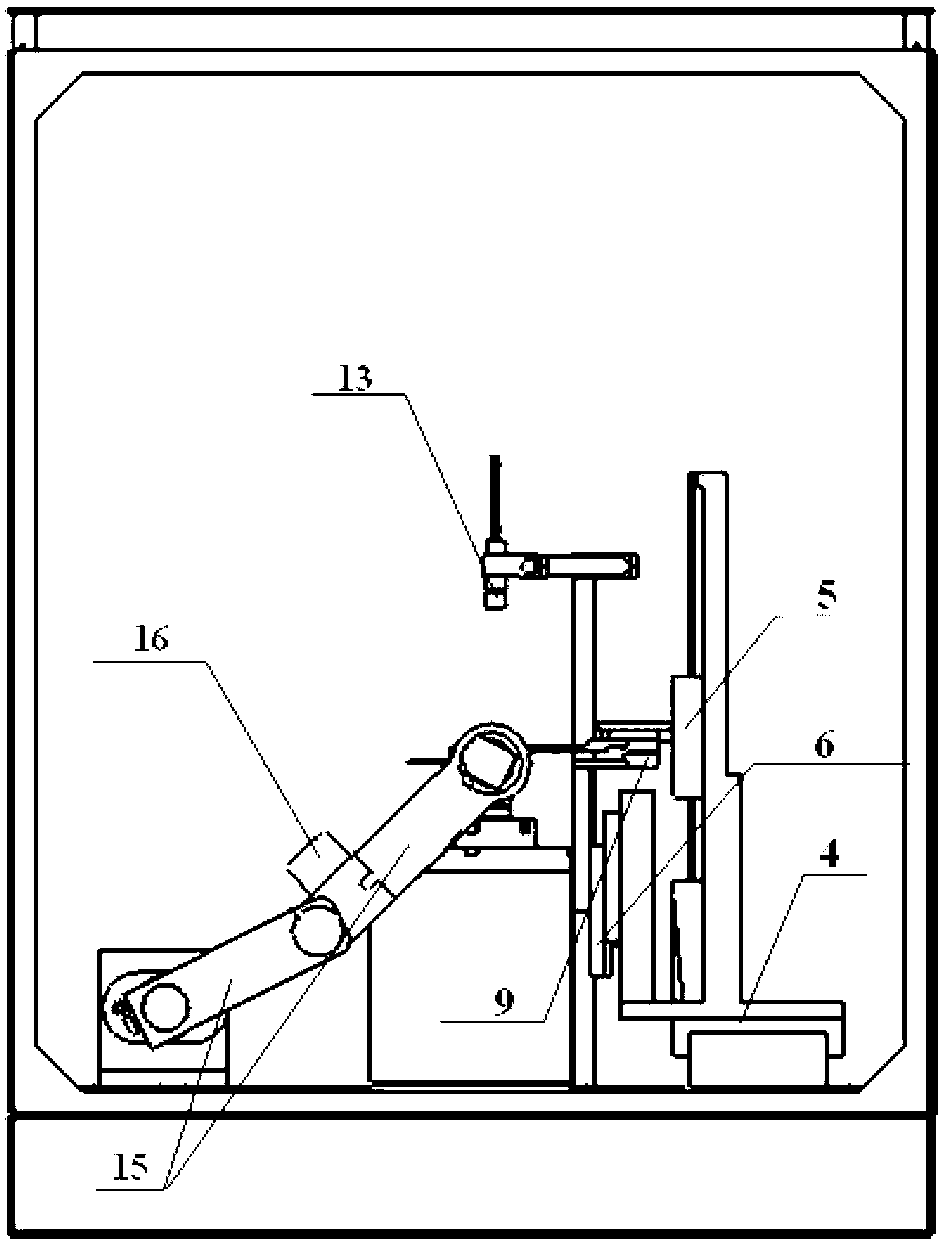

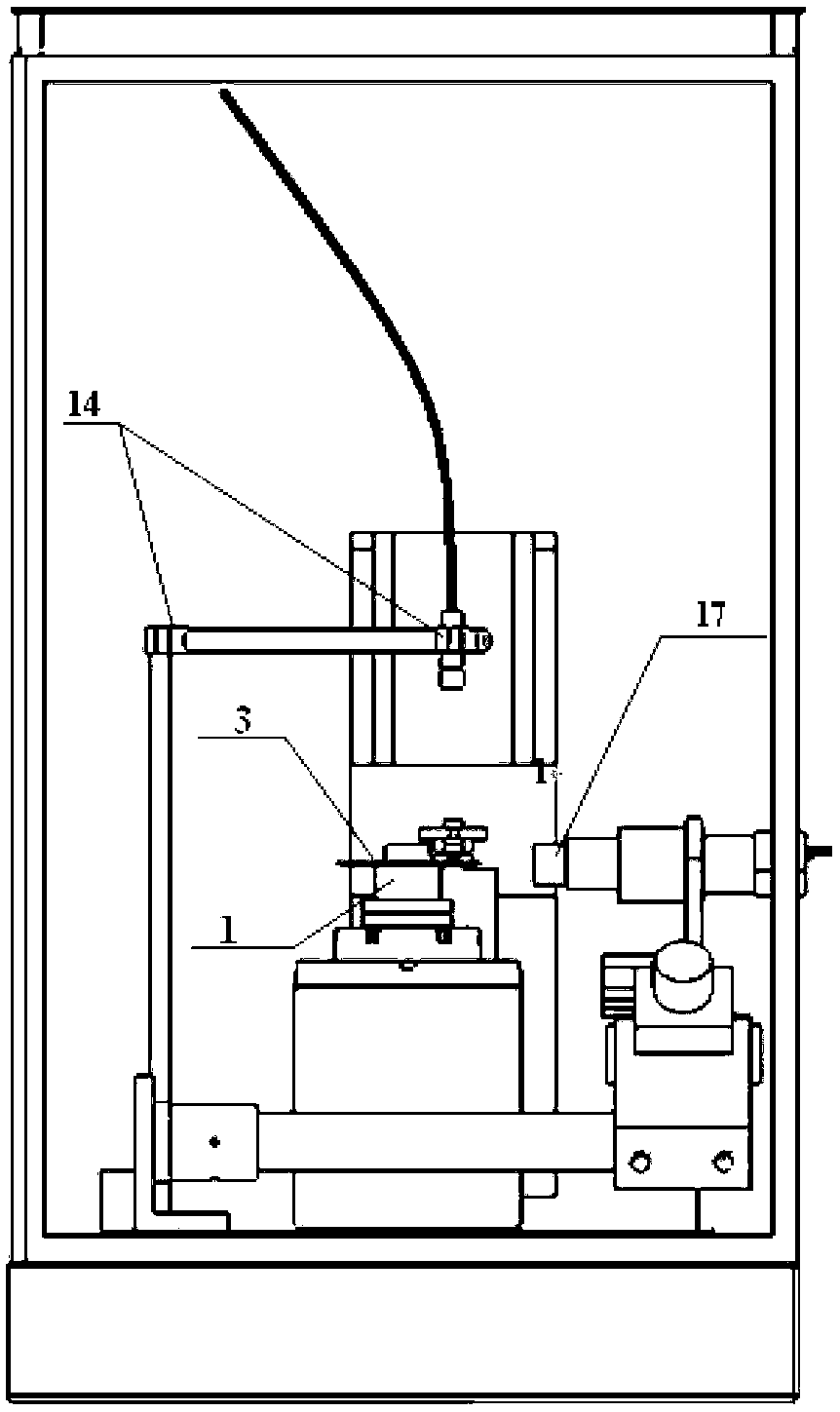

[0029] Figure 1-7 The reference signs in are: 1. Air levitation motor, 2. Negative pressure hole, 3. Film sample, 4. Planar sliding platform, 5. Vertical lifting platform, 6. Manual fine-tuning lifter, 7. Cantilever beam, 8 , nanoscale stretchable piezoelectric ceramic tube, 9, capacitive sensor, 10, impact ball fixture, 11, acoustic wave vibrometer sensor, 12, impact ball, 13, laser head of Doppler laser vibrometer, 14, Rotary hinge, 15, multi-degree-of-freedom microscope support, 16, displacement knob, 17, CCD microscope, 18, first support, 19, second support, 20, third support.

[0030] In this embodiment, the high-speed impact film tribology testing machine is mainly composed of a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com