Nano island film with enhanced Raman signal and method for preparing nano island film

A Raman signal and homogeneity technology, applied in the field of nano-island film preparation and detection, can solve the problems of poor uniformity and high cost of nano-island films, and achieve the effects of low cost, low preparation cost and reliable experimental results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

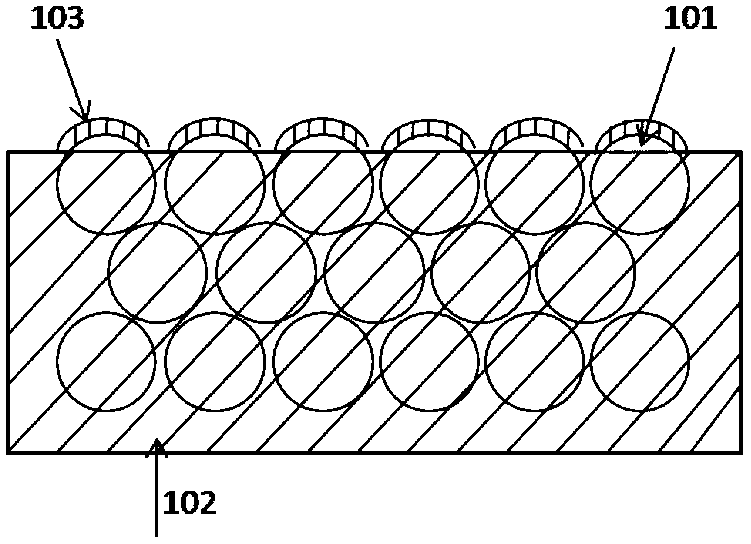

[0026] The preparation method of the nano-island membrane of the present invention:

[0027] Step 1) Prepare a silica ethanol solution with a volume ratio of 1:400~1:100, insert the glass slide vertically, and take out the glass slide after 3-5 days to obtain 3-5 layers distributed in an array And it is a silicon dioxide layer composed of closely arranged silicon dioxide particles;

[0028] The particle size of the silica particles is 50-500nm;

[0029] Step 2) Distribute silica gel baffles on both sides of the silica layer, and then pour polystyrene toluene solution with a volume ratio of 1:10 on the silica layer on the surface of the glass slide to cover the silica layer , dry for 3-5 days, after forming a solid polystyrene membrane, it will automatically fall off from the surface of the glass slide, so that the silicon dioxide particles on the solid surface of the polystyrene membrane protrude from the surface of the polystyrene membrane;

[0030] Step 3) Soak the diaphra...

Embodiment 1

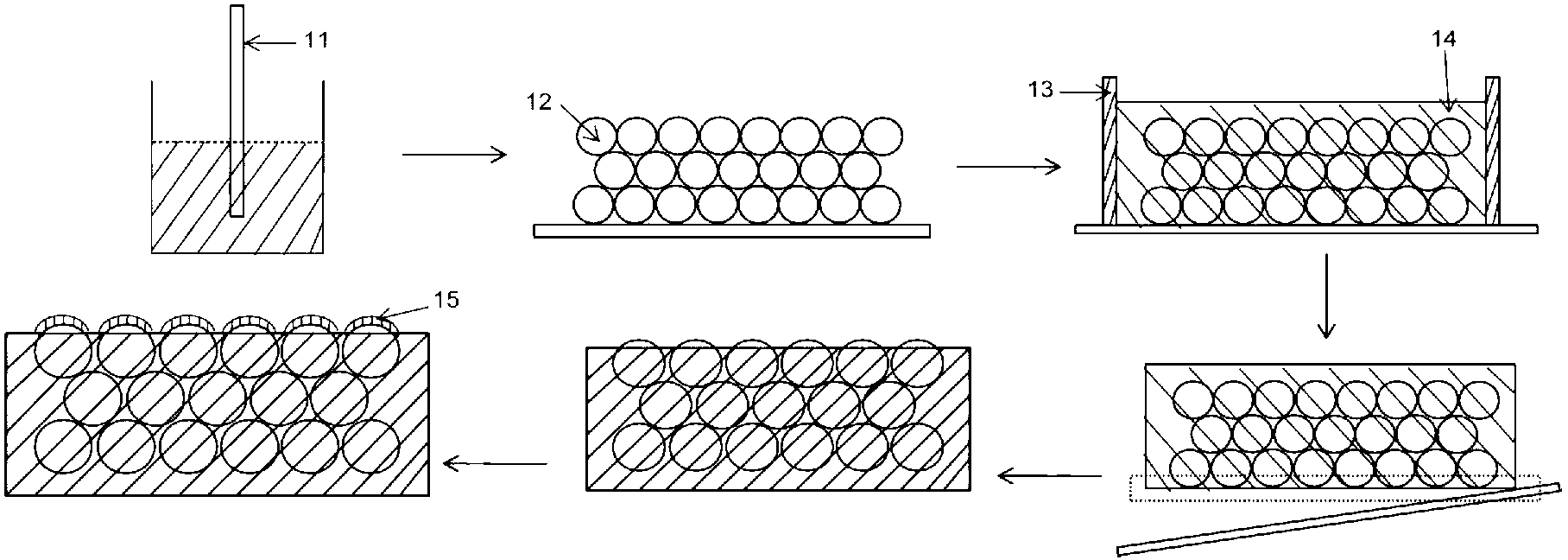

[0034] Embodiment 1: the preparation of a kind of nano-island film

[0035] Such as figure 2 As shown, configure a silicon dioxide / ethanol solution with a volume ratio of 1:200, insert the slide glass 11 vertically, and take out the slide glass after 3-5 days to obtain 3-5 layers of layers distributed in an array and in the form of The silicon dioxide layer 12 is composed of closely arranged silicon dioxide particles. Silica gel baffles 13 are arranged on both sides of the silicon dioxide layer. After pouring polystyrene / toluene solution 14 with a volume ratio of 1:10, dry for 3-5 days, and the polystyrene film will automatically fall off to obtain a dry product. Polystyrene membrane. On the side of the polystyrene membrane that is in contact with the glass slide, there will be some exposed silica. Put the polystyrene membrane into 50 ml of ethanol solution, add 30 microliters of 3-aminopropyltriethoxysilane, place it on a shaker at 150 rpm for 12 hours, then take it out a...

Embodiment 2

[0036] Embodiment 2: the preparation of a kind of nano-island film

[0037] Such as figure 2As shown, configure a silicon dioxide / ethanol solution with a volume ratio of 1:400, and insert the slide glass 11 vertically, and take out the slide glass after 3-5 days to obtain 3-5 layers of layers distributed in an array and in the form of The silicon dioxide layer 12 is composed of closely arranged silicon dioxide particles. Silica gel baffles 13 are arranged on both sides of the silicon dioxide layer. After pouring a polystyrene / toluene solution 14 with a volume ratio of 1:10, and drying for 3 days, the polystyrene film will automatically fall off, and dry polystyrene film can be obtained. vinyl film. On the side of the polystyrene membrane that is in contact with the glass slide, there will be some exposed silica. Put the polystyrene membrane into 50 ml of ethanol solution, add 30 microliters of 3-aminopropyltriethoxysilane, place it on a shaker at 150 rpm for 12 hours, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com