Surface plasmon lens integrated with metal nano-cavity

A surface plasmon and metal nanotechnology, applied in the field of nanophotonics, can solve problems that are not easy to realize and limit practical applications, and achieve the effects of easy processing, easy use, and high-quality preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the present invention will be further explained through examples in conjunction with the drawings.

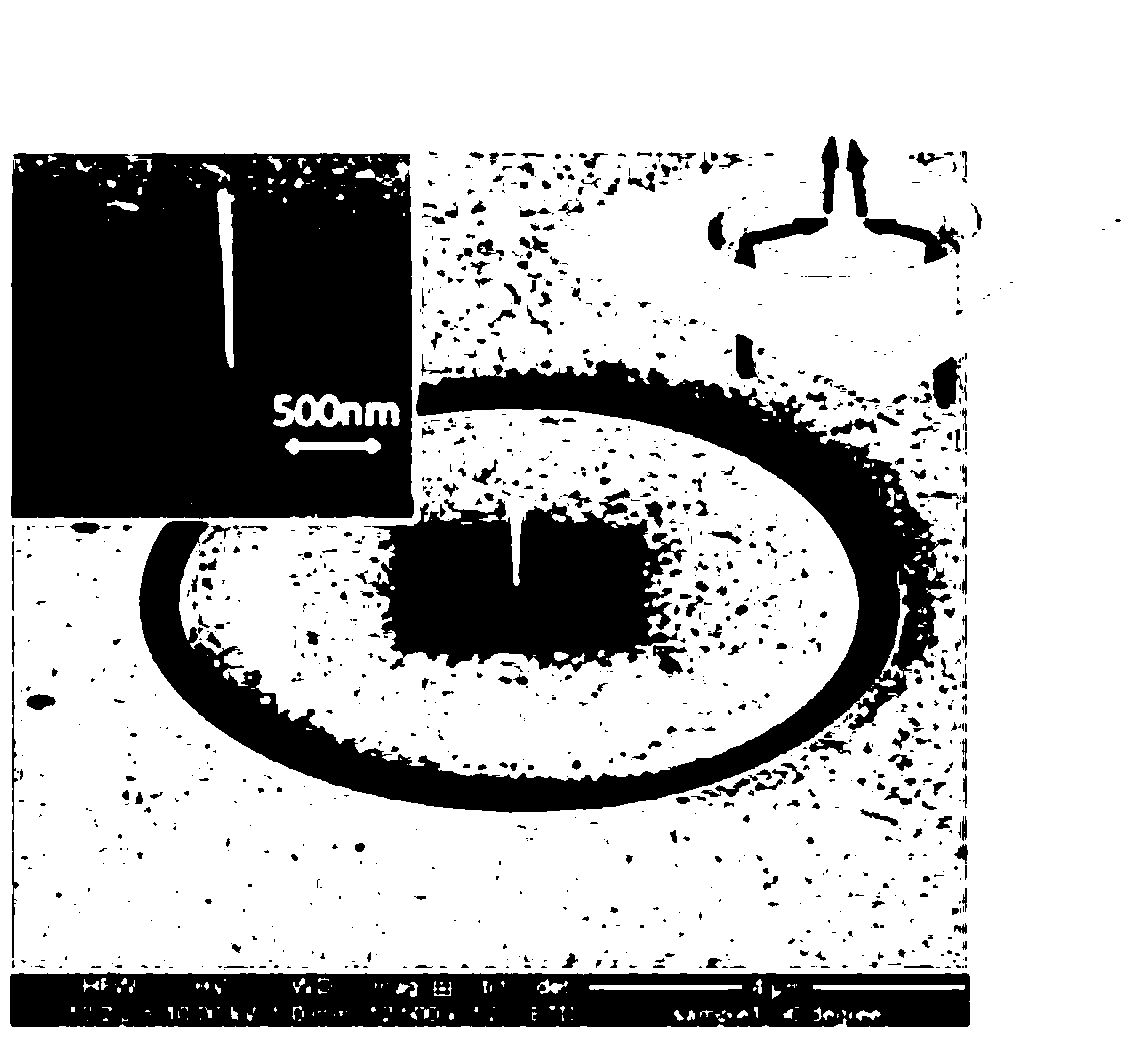

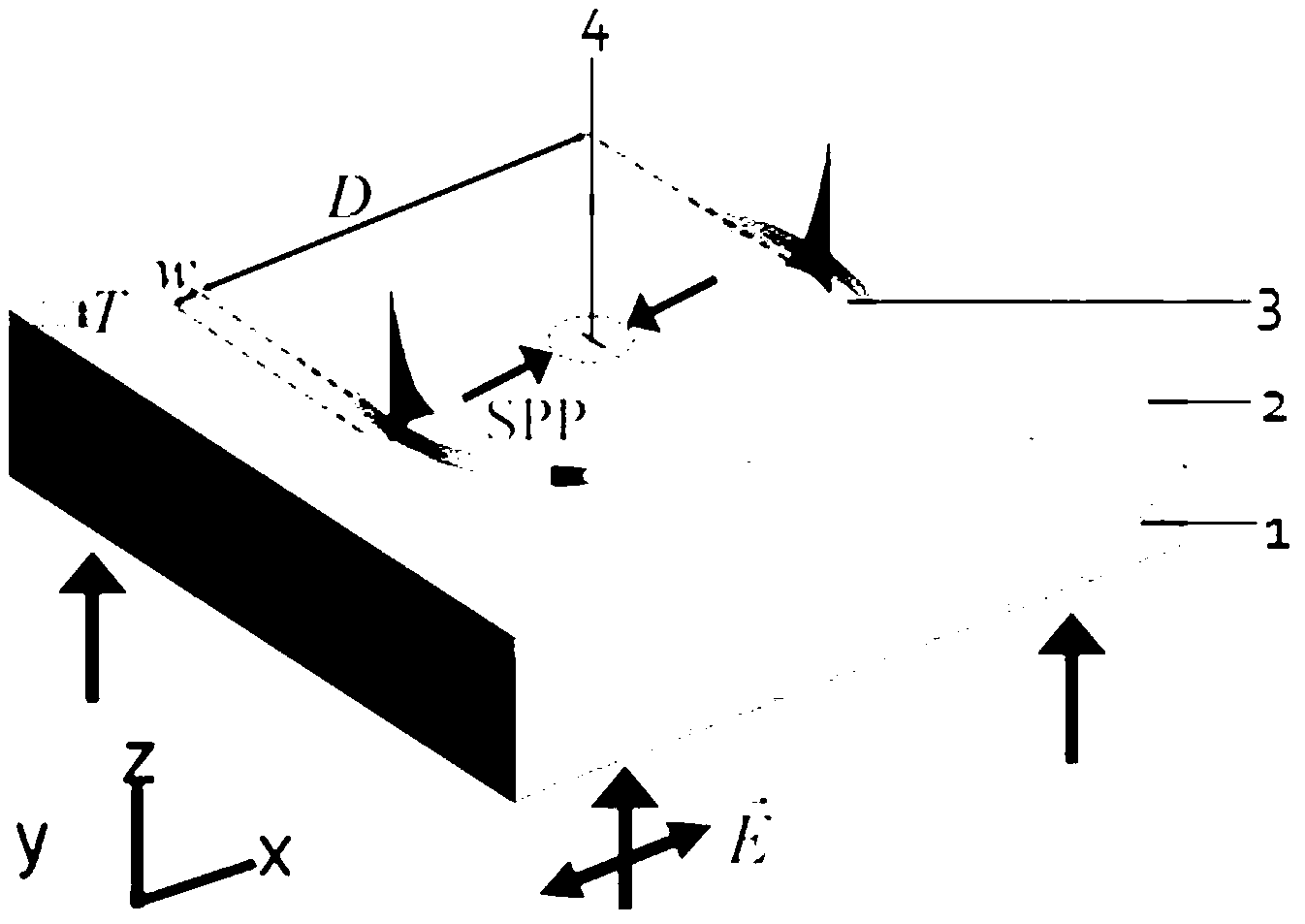

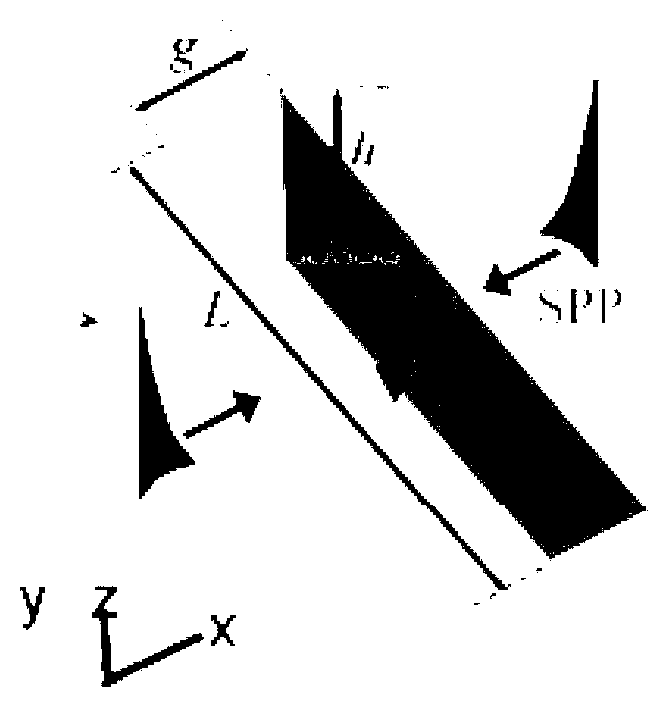

[0025] The surface plasmon lens of the integrated metal nanocavity of the present invention includes: a substrate 1, a gold film 2, a nano-slit ring 3 and a metal nanocavity 4; wherein the gold film 2 is plated on the upper surface of the substrate 1; The nano slit ring 3 is located on the gold film 2 and penetrates the gold film; and the metal nano cavity is a rectangular shallow groove located in the center of the nano slit ring, such as figure 2 Shown. The substrate uses optical glass.

[0026] Incident wavelength λ 0 Take 830nm, the corresponding refractive index of gold is 0.08+5i. The inner diameter D and the width w of the nano slit ring are 5m and 100nm, respectively. The thickness T of the gold film is selected as 750nm, so that the thickness of the remaining gold film from the bottom of the metal nanocavity to the upper surface of the substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com