Method for positioning bottle bodies on production line based on machine vision

A technology of machine vision and positioning method, applied in the field of visual positioning, can solve the problems such as the low positioning accuracy of template matching method, the inability to reduce the false detection rate of products, and the reduction of real-time detection process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

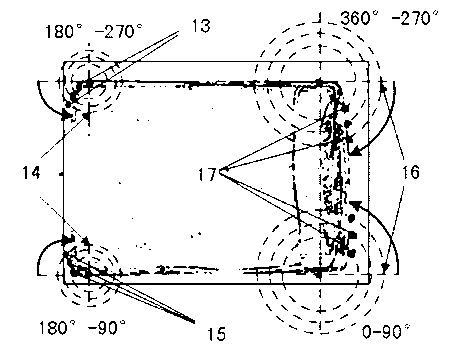

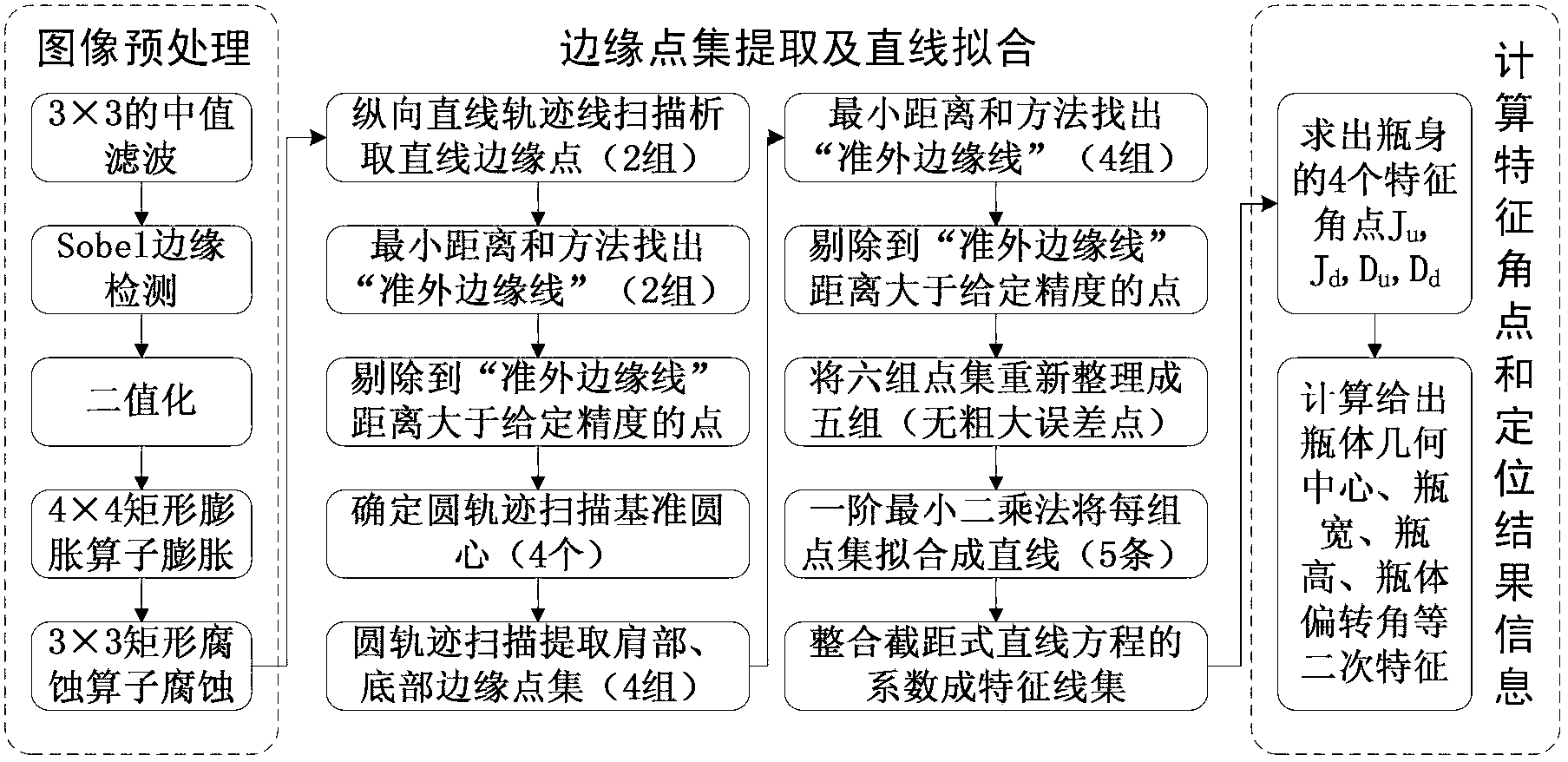

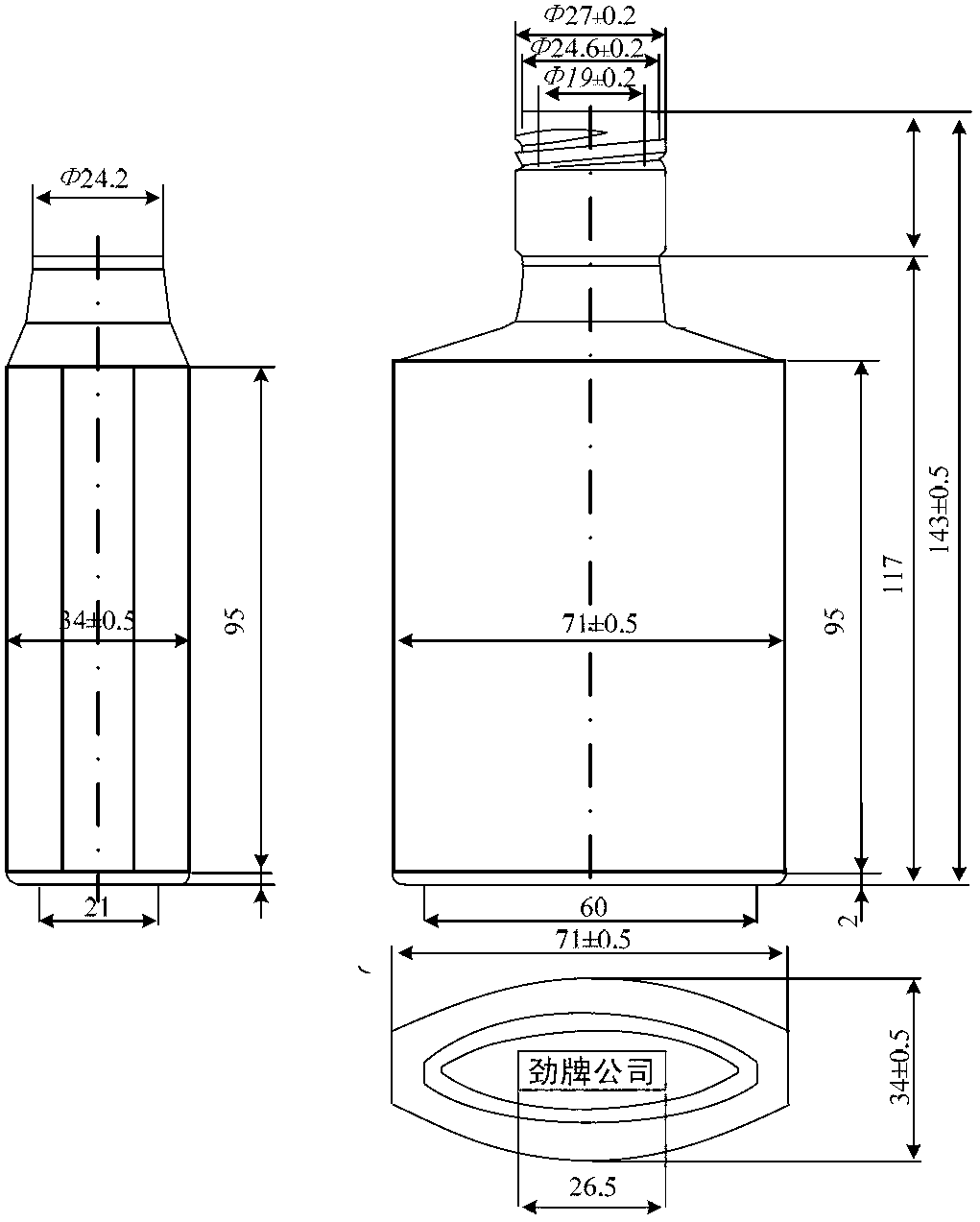

[0122] Such as figure 1 and figure 2 Shown, the special-shaped bottle body visual positioning method of the present invention, its concrete process is:

[0123] 1. Image preprocessing.

[0124] Since the image of the bottle body inevitably has various external and internal interferences during the process of sensing, collecting, transmitting, and processing, it is necessary to perform specific preprocessing operations on the image before positioning. Considering not to lose too much edge detail while filtering, the present invention first performs a 3×3 median filtering operation on the original image. Then use the Sobel edge detection operator to perform edge detection on the filtered image, and give a threshold of 8 to binarize the edge image; next, use a 4×4 rectangular expansion operator to perform an expansion operation on the initial edge image; Then use a 3×3 rectangular erosion operator to perform an erosion operation on the expanded edge image.

[0125] 2. Extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com