Anti-counterfeiting label with ultraviolet-cured glue film

An anti-counterfeiting label and ultraviolet light technology, applied in the field of adhesives and anti-counterfeiting labels, can solve the problems of no public anti-counterfeiting labels, no public adhesive tape anti-counterfeiting labels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0197] Example 1: RFID anti-counterfeiting label with UV-curable adhesive film

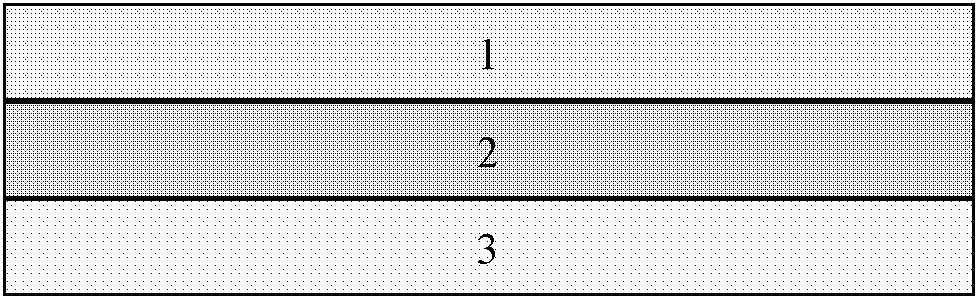

[0198] The RFID anti-counterfeiting label is composed of the following three layers: 1) PET surface material layer with RFID printed circuit and chip; 2) UV-curable adhesive film; 3) PET release film (Xiamen long days).

[0199] The RFID anti-counterfeiting label is made of a PET surface material layer with an RFID printed circuit and a chip attached to a UV-curable adhesive film on a PET release film.

[0200] Operation: 1) Irradiate 1.0-2.0J / cm through the PET release film 2 UV light with a wavelength of 260 to 380nm; 2) Peel off the PET release film within 5 minutes of open time, and stick the label on the substrate to be pasted; 3) The film is cured after 72 hours at room temperature. The label parameters, usage conditions and experimental results of Example 1 are shown in Table 6.

[0201] Table 6. Tag parameters, usage conditions and experimental results

[0202]

[0203] After the fi...

Embodiment 2

[0205] The RFID and laser holographic anti-counterfeit labels with UV-curable adhesive film were prepared according to Example 1, the difference being that: the UV-curable adhesive film contained EVA components, and the anti-counterfeit surface material layer was RFID and laser holographic surface material layer.

[0206] The anti-counterfeiting label is composed of the following three layers: 1) PET surface material layer or laser holographic surface material layer with RFID printed circuit and chip; 2) UV-curable adhesive film; 3) PET surface material layer that can transmit ultraviolet light Release film (Xiamen Changtian).

[0207] The PET surface material or laser holographic surface material with RFID circuit and chip is directly attached to the adhesive film surface of the PET release film with adhesive film to obtain a UV-curable adhesive film; and PET release film RFID anti-counterfeiting labels or laser holographic anti-counterfeiting labels.

[0208] Operation: 1) ...

Embodiment 3

[0212] Example 3: Laser holographic anti-counterfeiting label with UV-curable adhesive film

[0213] A laser holographic anti-counterfeiting label with a UV-curable adhesive film was prepared according to Example 1, except that the UV-curable adhesive film contained methacrylate, and the anti-counterfeit surface material layer was a laser holographic surface material layer.

[0214] The laser holographic anti-counterfeiting label structure with UV-curable adhesive film consists of the following three layers: 1) laser holographic anti-counterfeiting surface material (PET and paper); 2) UV-curable adhesive film; and 3) UV-transmissible PET release film (Micron) with a thickness of 50 μm.

[0215] The PET or paper surface material with the laser holographic anti-counterfeiting function label is directly attached to the adhesive film surface of the PET release film with the adhesive film, and the laser holographic anti-counterfeiting with the UV-curable adhesive film and the PET r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com