A kind of cement teaware preparation process based on inverted mold technology

A preparation process and tea utensil technology, which is applied in the field of cement handicraft preparation, can solve the problems of destroying the tea appreciation situation, etc., and achieve the effect of cheap materials, low energy consumption, simple preparation method and curing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

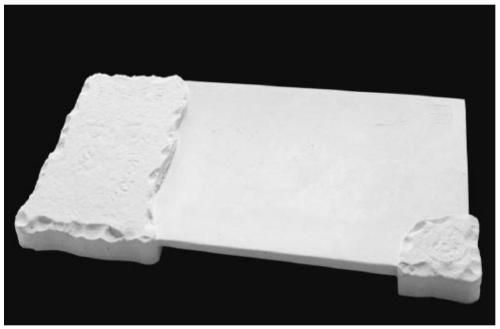

[0034] A kind of cement tea set (cement tea tray) preparation technology based on inverted mold technology, comprises the following steps:

[0035] 1) Mold frame preparation: choose the Wujinshi tea tray prepared to be molded as a template, and its specific size is 580mm×270mm×80mm, and use 12 10mm long nails to support the tea tray in the center of the cardboard mold frame with a size of 60cm×30cm×12cm ;

[0036] 2) Preparation of mold pouring material: choose 903 translucent silica gel as the mold pouring material, weigh about 18L of silica gel according to the volume of the mold frame, add curing agent and mix (tetraethyl silicate, the additive accounts for 2% of the mass of silica gel), and then add cement ( Accounting for 1% of the mass of silica gel), stir evenly as mold pouring material;

[0037] 3) Mold preparation: Pour the mold pouring material into the mold frame until it exceeds 10mm from the top of the tea tray, carefully remove the air bubbles in the silica gel,...

Embodiment 2

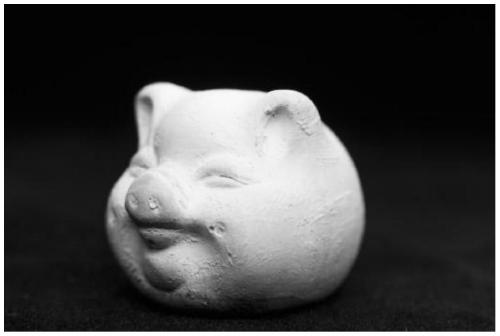

[0041] A kind of cement tea utensil (cement tea pet) preparation technology based on inverted mold technology, comprises the following steps:

[0042] 1) Mold frame preparation: choose the tea pet that is ready to be molded as a template, and its specific size is 50mm×30mm×30mm, and use 4 10mm long nails to support the tea tray in the center of the cardboard mold frame with a size of 60mm×50mm×50mm middle;

[0043] 2) Prepare mold pouring material: choose 903 translucent silica gel as the mold pouring material, weigh about 150ml of silica gel according to the volume of the mold frame, add curing agent and mix (tetraethyl silicate, the additive accounts for 1% of the mass of silica gel), and stir evenly to make a mold pouring material;

[0044] 3) Mold preparation: pour the mold pouring material into the mold frame until it exceeds 10mm from the top of the tea pet, carefully remove the air bubbles in the silica gel, let it stand for about 40 minutes, and then remove the mold a...

Embodiment 3

[0048] A kind of cement tea set (cement teacup) preparation process based on inverted mold technology, comprises the steps:

[0049] 1) Mold frame preparation: select the tea cup to be molded as the template, its specific size is 40mm (cup mouth diameter) × 30mm (height) × 10mm (cup bottom diameter), use 4 10mm long nails to fix the tea tray Centered and supported in a cardboard formwork with a size of 50mm×50mm×40mm;

[0050] 2) Prepare mold pouring material: choose 903 translucent silica gel as the mold pouring material, weigh about 105ml of silica gel according to the volume of the mold frame, add curing agent and mix (tetraethyl silicate, the additive accounts for 1% of the mass of silica gel), and stir evenly to make a mold pouring material;

[0051] 3) Mold preparation: Pour the mold pouring material into the mold frame until it exceeds 10mm from the top of the tea cup, carefully remove the air bubbles in the silica gel, let it stand for about 40 minutes, and then remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com