A process for the recovery of volatile aroma compounds from vegetable material

A plant material, volatile technology, applied in tea spices, food science, essential oils/spices, etc., can solve problems such as inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The invention is now demonstrated using examples. The examples are for illustration only and do not limit the scope of the invention in any way.

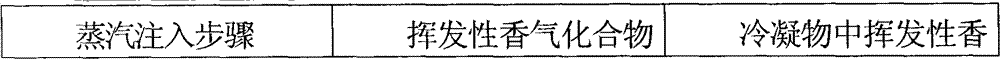

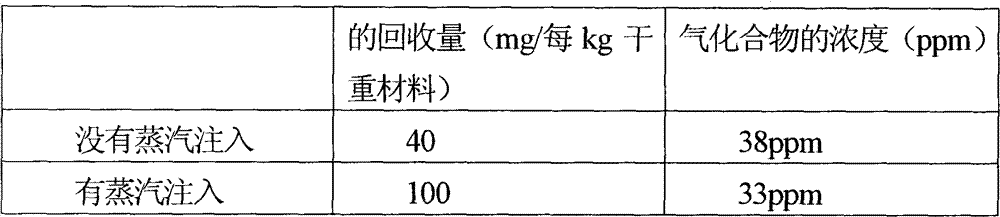

[0071] Effect of Injected Steam

[0072] The experiment was carried out by exposing 180 g of black tea leaves (from Kenya) as plant material to air. The temperature of the air entering the dryer was 110° C., and the moisture content was 11 g / kg of dry air. The plant material contained 2.33 kg of moisture per kg dry weight of plant material. The flow rate of air entering the dryer was 3.2 kg / hr. The total air exposure was 40 kg per kg dry weight of plant material. Dryer exhaust consists of an air stream carrying aroma volatiles and moisture released from the plant material during the drying process. Injection of steam at a temperature of 100°C and a rate of 96 g / hr into the dryer exhaust stream produces a gaseous mixture. The amount of steam added was 30 g / kg of gaseous mixture. The gaseous mixture was fed to a spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com